Electric vacuum pump for automobile

A technology for electric vacuum pumps and automobiles, applied to pumps, parts of pumping devices for elastic fluids, pump components, etc., can solve the problems of easy damage, reduced service life of vacuum pumps, etc., to ensure service life and best braking effect good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

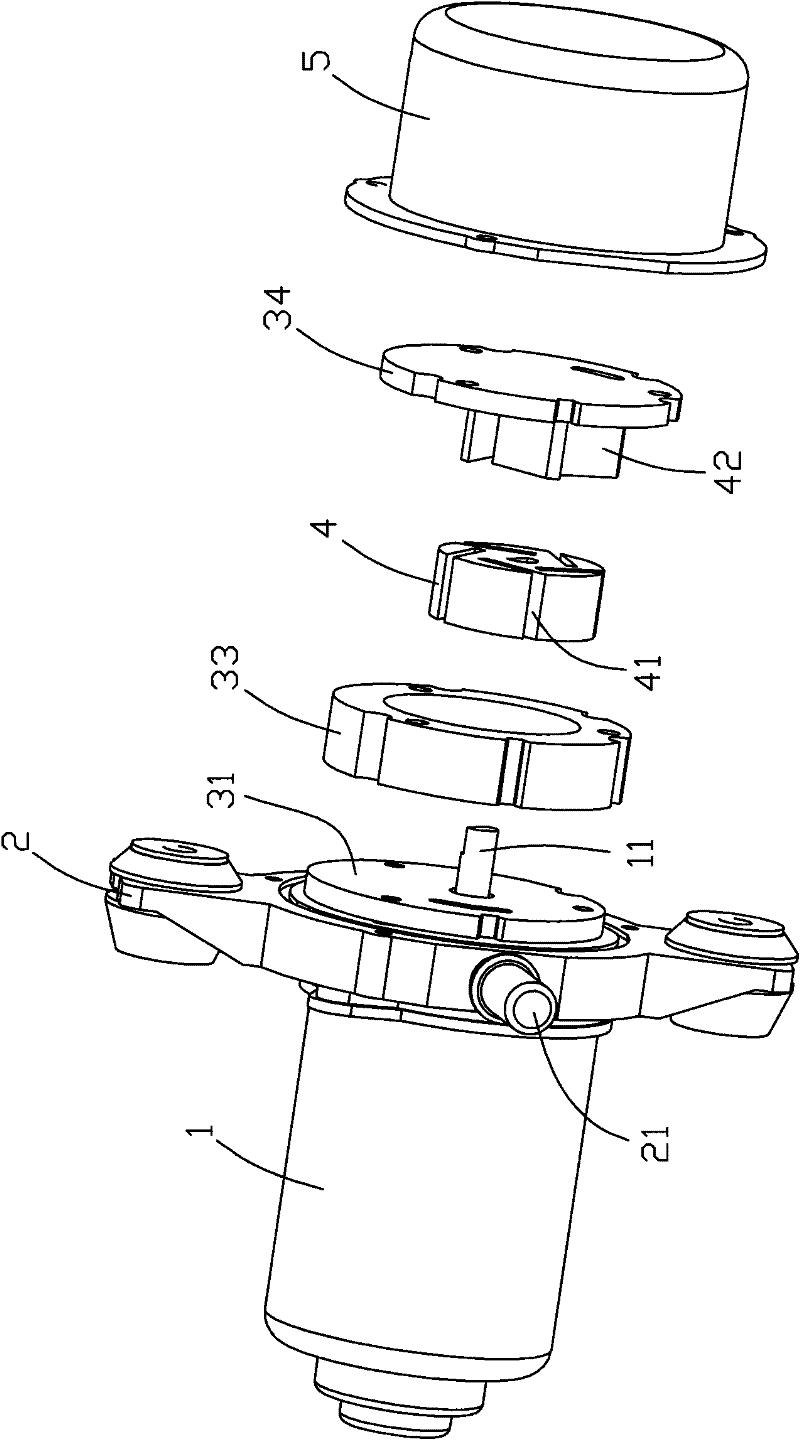

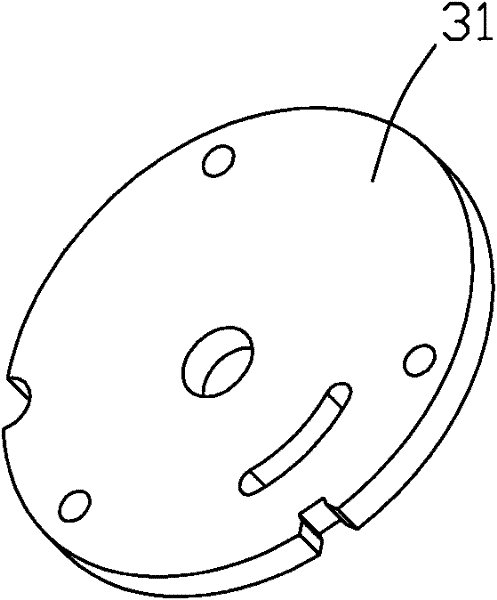

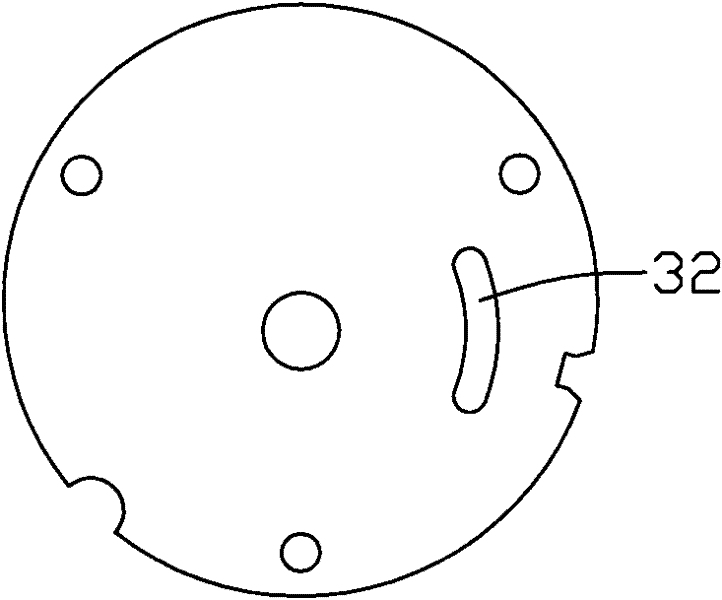

[0027] Such as Figure 1 to Figure 11 As shown, the electric vacuum pump for automobiles of the present invention includes a motor assembly 1, a housing 2, a stator assembly 3, a rotor 4 and a gland 5, and the housing 2 is provided with an air inlet 21 and an air outlet 22, and the stator assembly 3 It forms a radial eccentricity with the output shaft 11 of the motor assembly 1. The blade 42 is slidably connected to the rotor 4. The stator assembly 3 includes a stator seat 31, a stator 33 and a stator cover 34 in sequence. The air inlet slot 32 communicated with the air port 21 , the stator cover 34 is provided with an air outlet slot 35 communicated with the air outlet 22 of the housing 2 , and the axial width of the stator 33 corresponds to the vane 42 . The air intake slot 32 is arc-shaped, and the arc-shaped air intake slot 32 corresponds to the arc shape of the rotor 4 and is arranged at the outer circumference of the rotor 4 . The air outlet groove 35 is arc-shaped, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com