Testing device for unconfined compression fluid deformation of solution environmental action rock mass

A test device and environment technology, applied in the field of uniaxial rheological test device, can solve the problems of insufficient attention to the rheological law of rock mass, and achieve the effect of easy disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

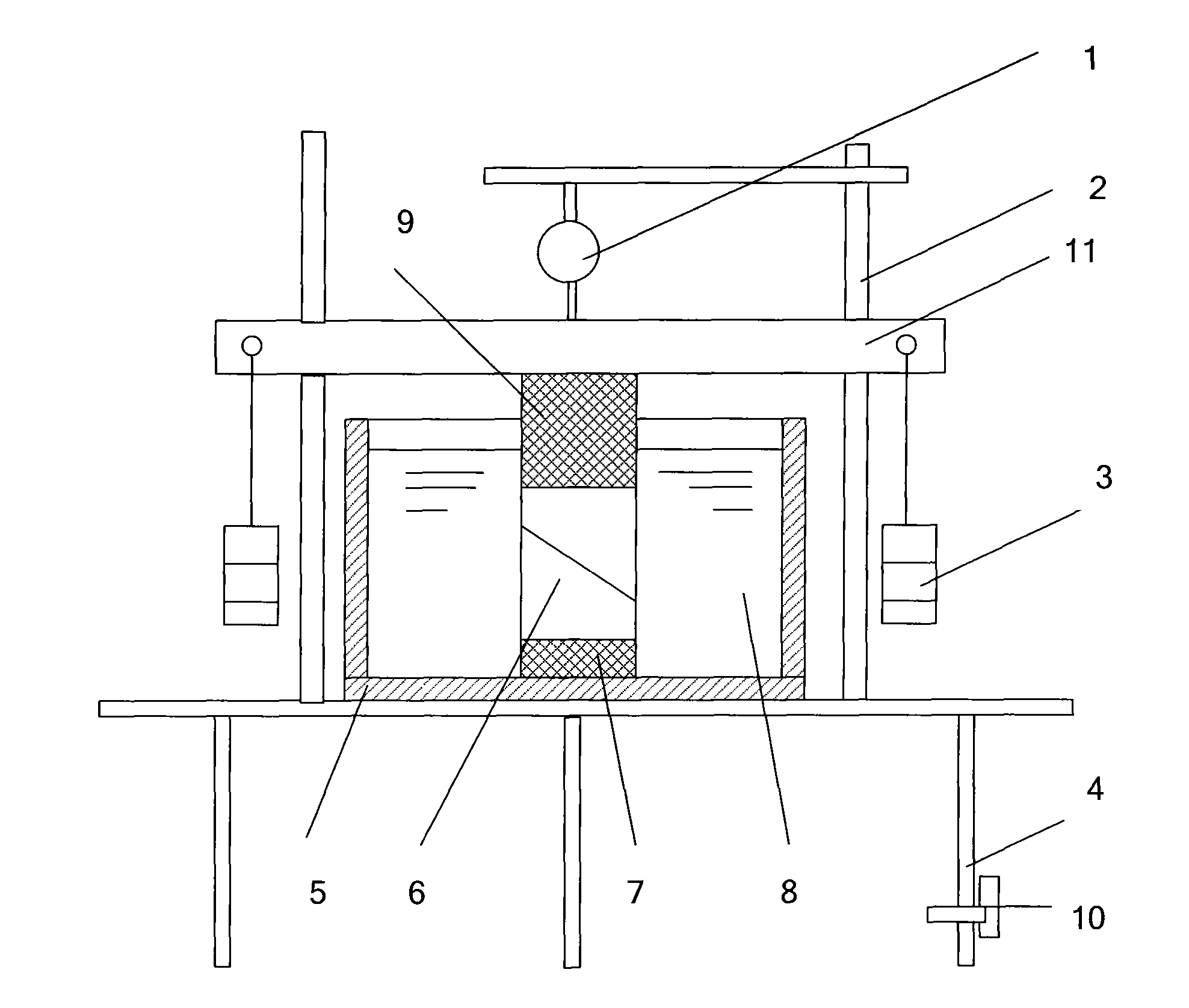

[0016] Embodiment 1: as figure 1 The rock mass unconfined compression rheological test device for the solution environment effect shown in the figure includes: a corrosion-resistant solution cylinder 5, a corrosion-resistant base 7, a corrosion-resistant pressure head 9, a fixed rod frame 2 and a pressure rod 11; the corrosion-resistant base 7 is fixed At the bottom of the corrosion solution cylinder 5; the fixed rod frame 2 is located on both sides of the corrosion solution cylinder 5, and the pressure rod 11 is arranged on the fixed rod frame 2, directly above the corrosion solution cylinder 5, and can move up and down along the fixed rod frame 2; Corrosion-resistant pressure head 9 is provided at the position corresponding to corrosion-resistant base 7 at the lower part of pressure rod 11; Between the corrosion-resistant indenter 9, load weights 3 at both ends of the pressure rod 11, and at the same time, a displacement dial indicator 1 (which can be replaced by a displacem...

Embodiment 2

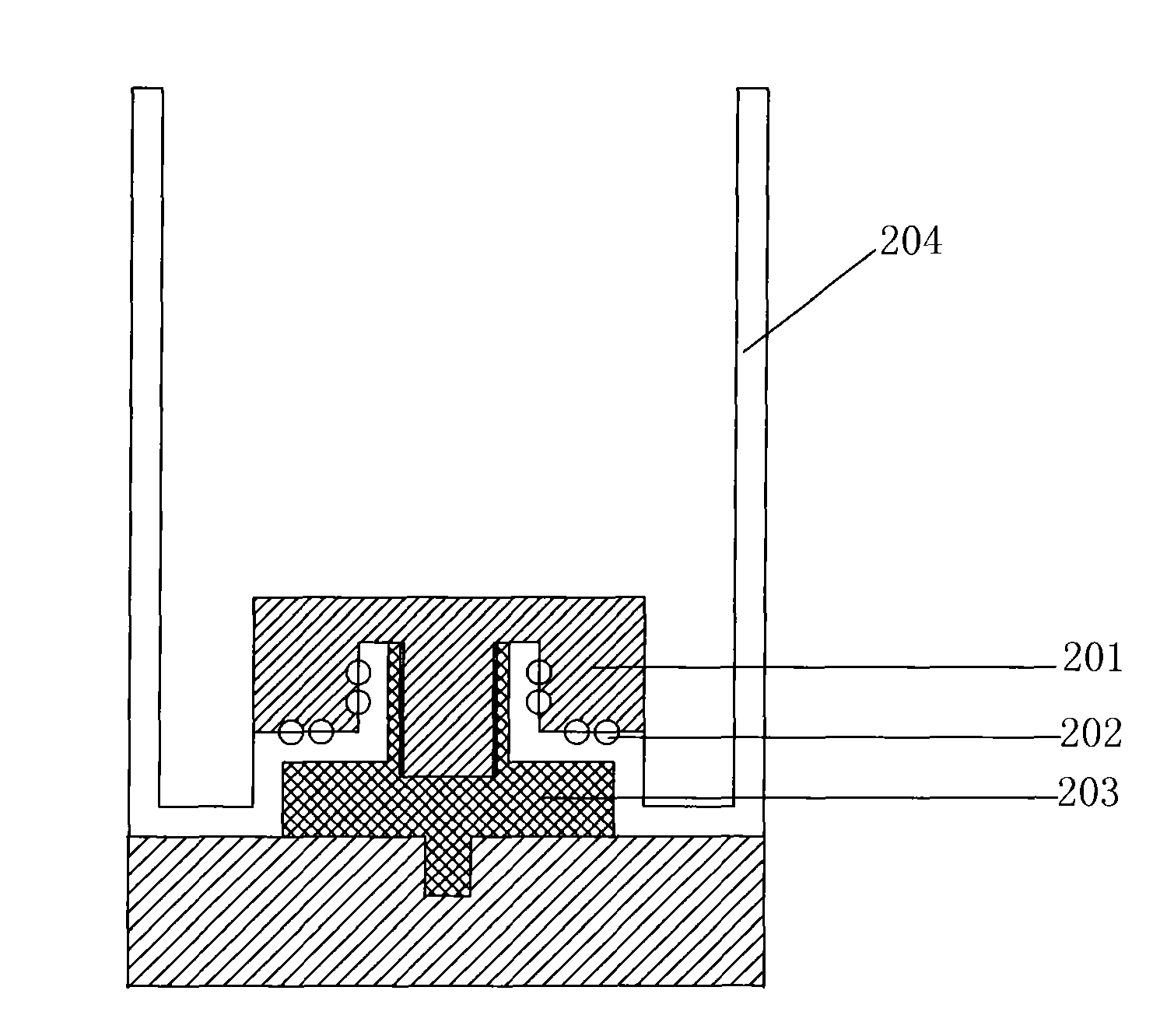

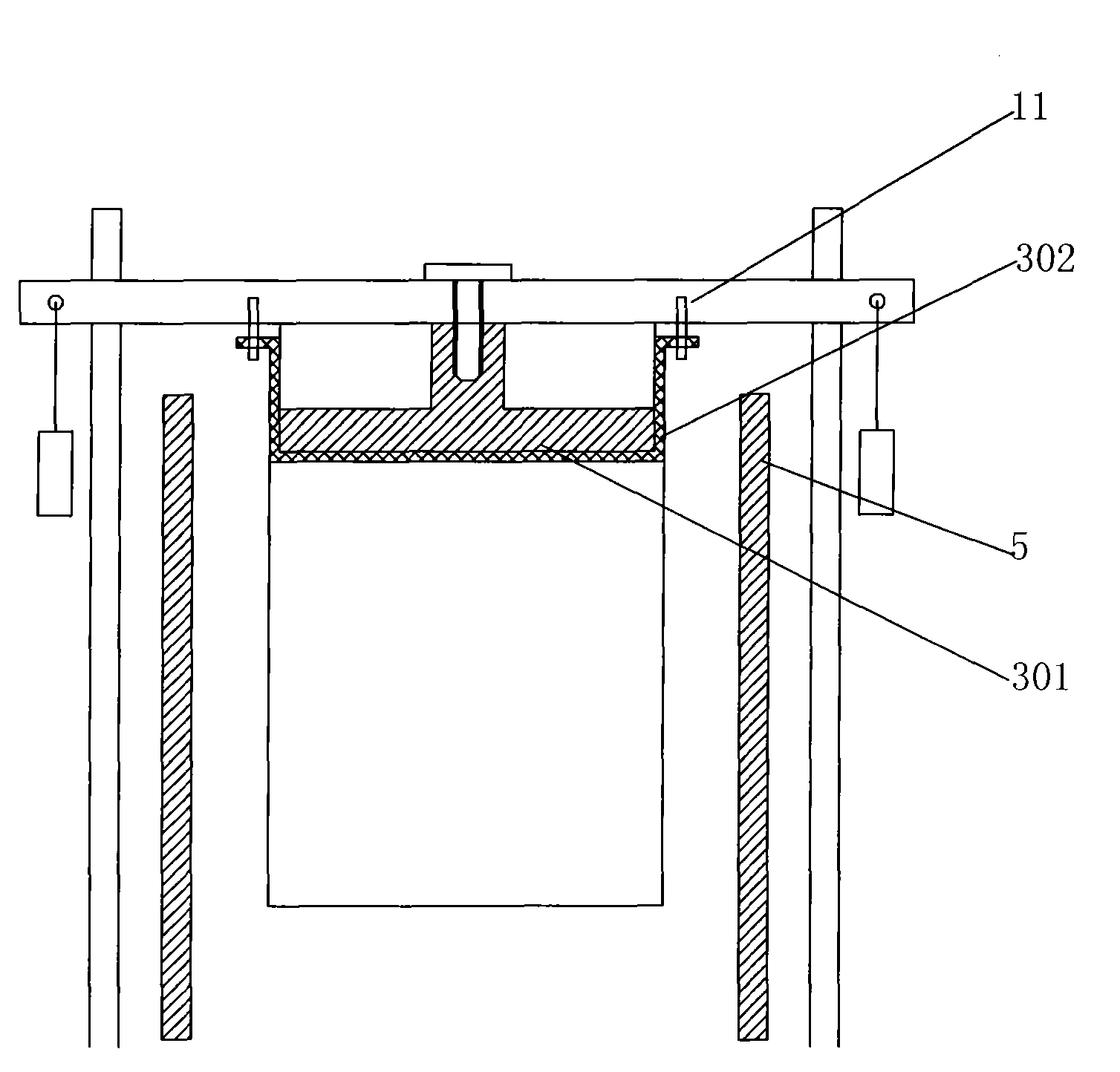

[0017] Embodiment 2: For the convenience of application, the corrosion-resistant base 7 and the corrosion-resistant pressure head 9 are made into detachable structures, such as figure 2 and image 3 As shown, wherein the corrosion-resistant base 7 includes: the bottom pressure head 201 of the test piece and the connecting block 203; the connecting block 203 is connected with the bottom of the corrosion solution cylinder 5 by threads, and a rubber protective layer 201 is arranged on the outside thereof, and the rubber protective layer 201 is covered with the entire inner wall of the corrosion solution cylinder 5; the bottom indenter 2 of the test piece is fastened with the connecting block 4 through threads, and a sealing rubber ring 3 is provided at the joint, so that the bottom indenter 2 of the test piece and the rubber protective layer 201 are tightly connect. The corrosion-resistant indenter 9 includes: the test piece top pressure head 301 and the corrosion-resistant lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com