Automatic ultrasonic scanner for welding lines of large workpieces

A technology for large workpieces and scanners, used in instruments, material analysis using sonic/ultrasonic/infrasonic waves, scientific instruments, etc., can solve problems such as difficulties in automatic detection of scanners, and achieve strong and durable loading and unloading, convenient loading and unloading, guaranteeing Effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

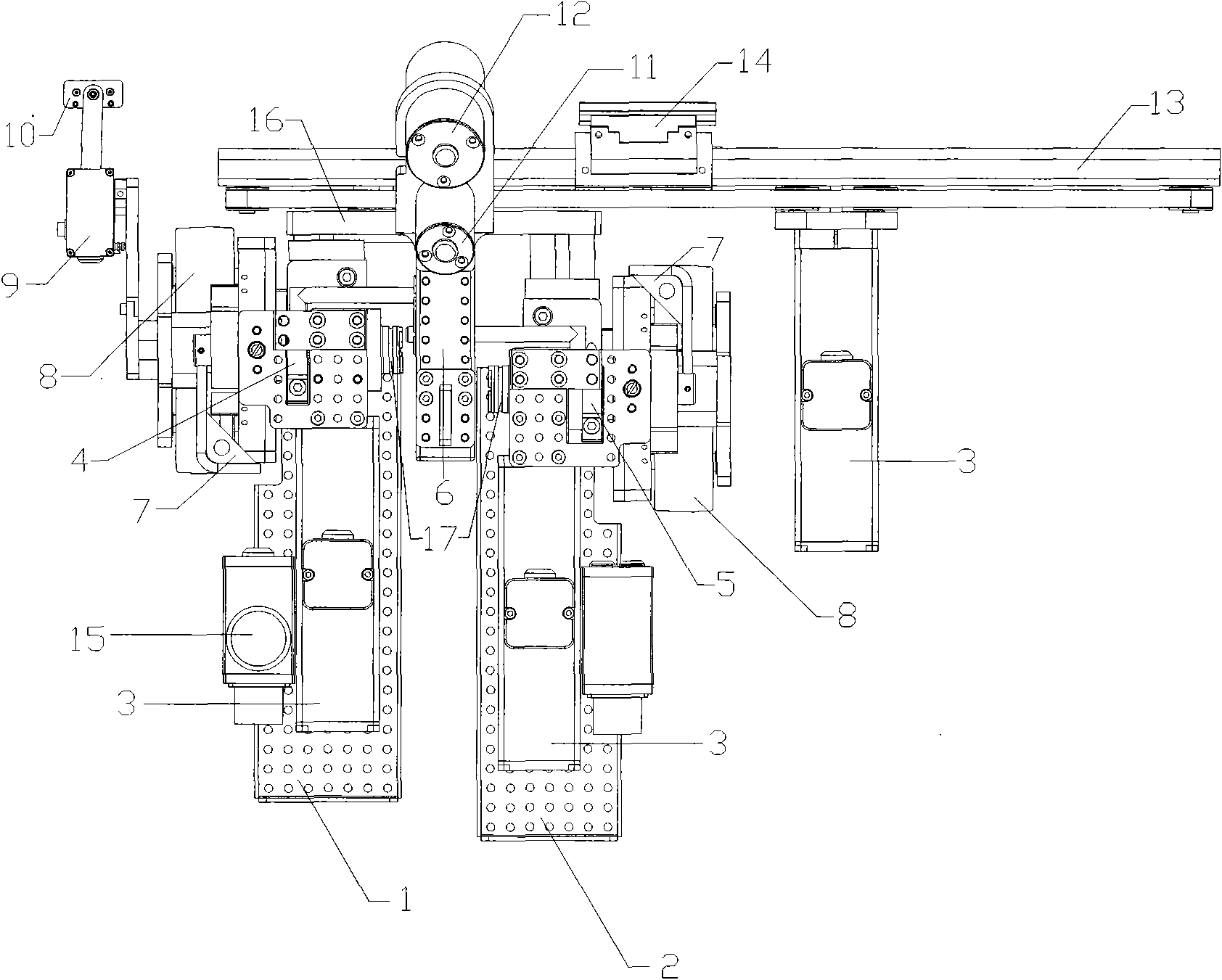

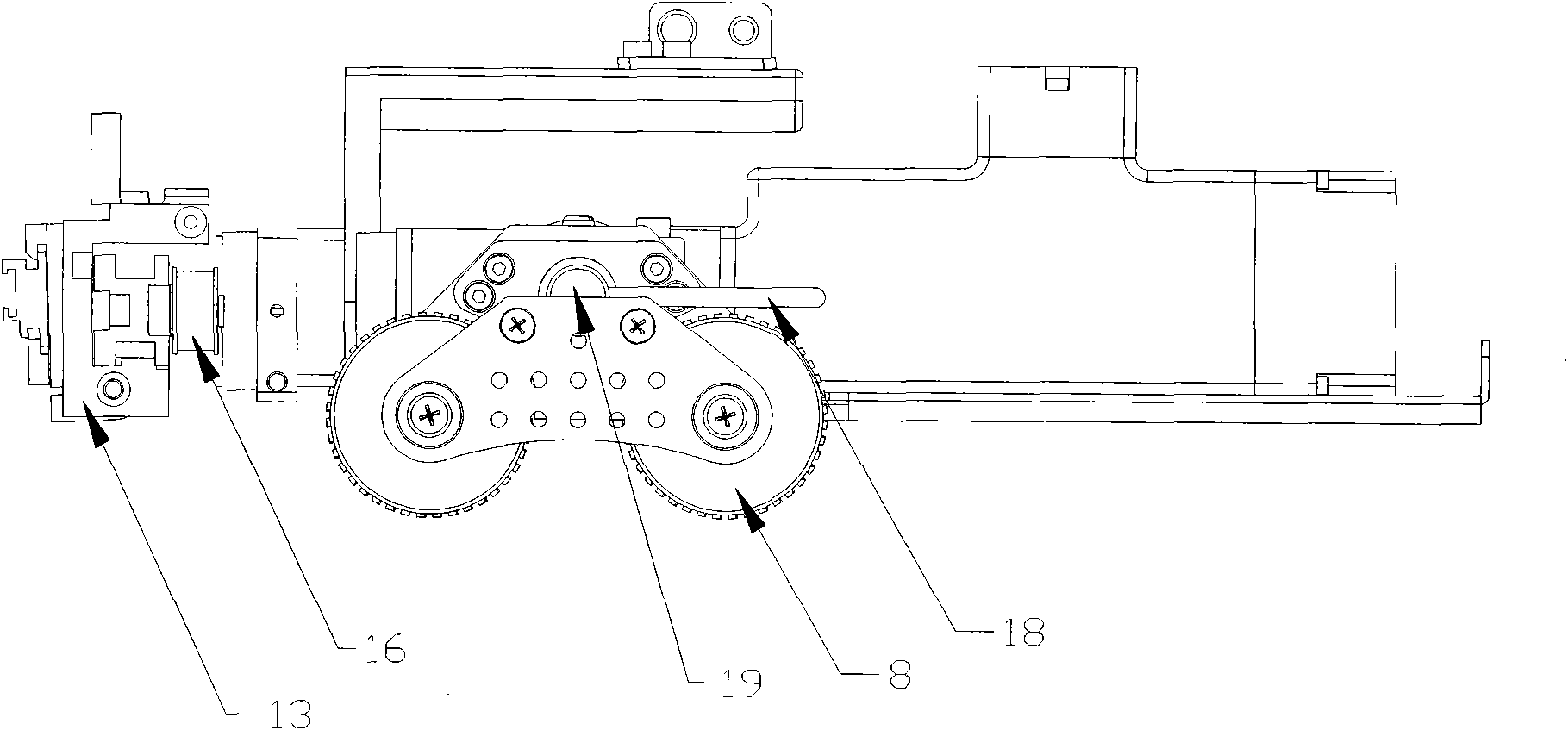

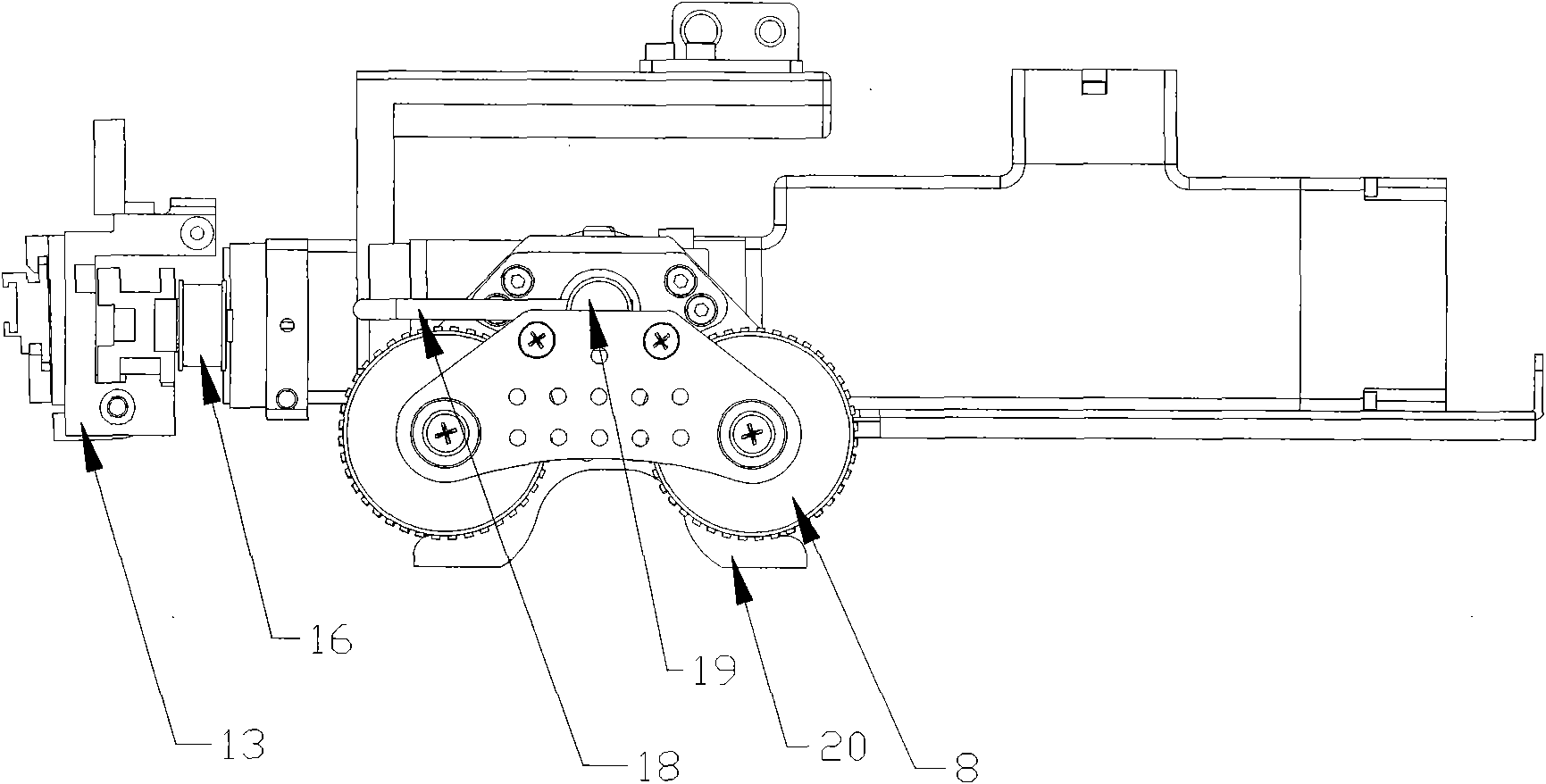

[0019] see Figure 1-3 , the present invention provides an automatic ultrasonic scanner for large workpiece welds, comprising a main frame I1 and a main frame II2, the main frame I and the main frame II are arranged left and right, and magnetic wheels 8 are respectively installed below them, and the magnetic wheels The wheels are two groups of left and right, and each group includes two front and rear magnetic wheels. The magnetic wheels of each group are respectively connected under the main frame I and the main frame II through their respective magnetic wheel frames. The main frame I and the main frame The IIs are connected by an adjustable connection that can adjust the mutual longitudinal rotation angle. Thus by changing the longitudinal angle between the main frame I and the main frame II, the inclination angle between the left and right magnetic wheels respectively installed under the main frame I and the main frame II can be changed to adapt to workpieces with different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com