Method for pressing layer gasket of rigid-flexible product

A technology of gaskets and products, applied in the field of lamination of rigid-flex product layer gaskets, can solve the problems of uneven board surface, easy to fall, gasket corners, curvatures and rigid boards and other problems, so as to maintain the board surface smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further elaborate the technical means and effects adopted by the present invention to achieve the predetermined purpose, please refer to the following detailed description and accompanying drawings of the present invention. It is believed that the purpose, characteristics and characteristics of the present invention should be able to gain a deep and specific understanding from this , however, the accompanying drawings are provided for reference and illustration only, and are not intended to limit the present invention.

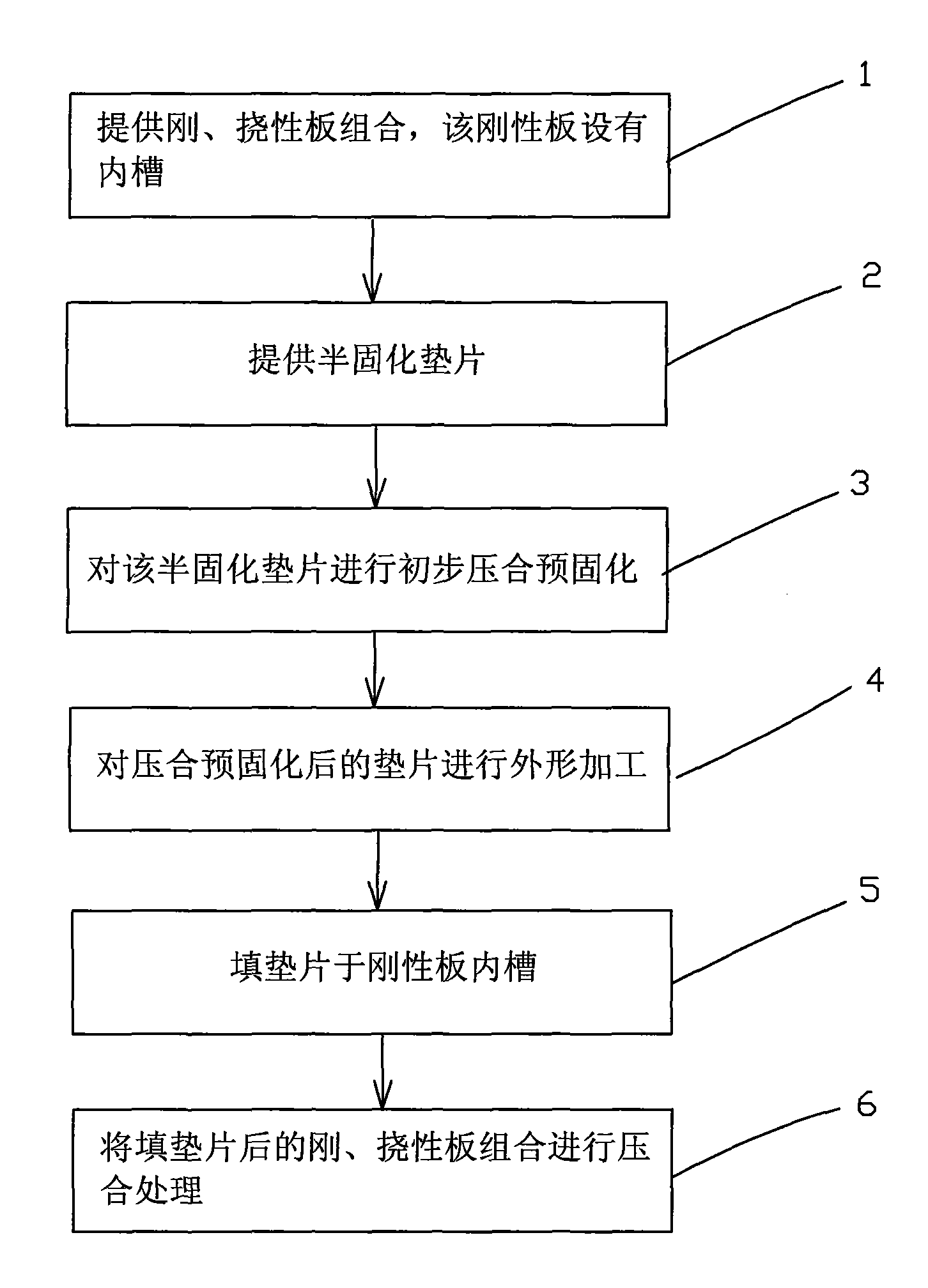

[0021] Such as figure 1 As shown, the pressing method of the rigid-flexible product layer gasket of the present invention includes:

[0022] Step 1, providing a combination of rigid and flexible boards, the rigid board is provided with an inner groove. The step 1 includes step 1.1, processing the semi-finished products of the rigid board; step 1.2, processing the semi-finished products of the flexible board; and step 1.3, pre-laminating the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com