Duplex sawing lumbering technology

A technology, a sawing technology, applied in the field of duplex sawing and lumber making, can solve the problems of complex lumber making equipment and few applications, and achieve the effect of increasing the proportion and broadening the prospect of production and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

[0014] Taking a log with a diameter of 400mm as an example, only sawing a board of one specification, the scanning of the log is carried out on a medical CT. figure 1 It is a 3D log model obtained by applying 3D reconstruction technology after tomographic scanning of the log (the tree species is white ash, with a diameter of 400mm and a scanning length of 700mm).

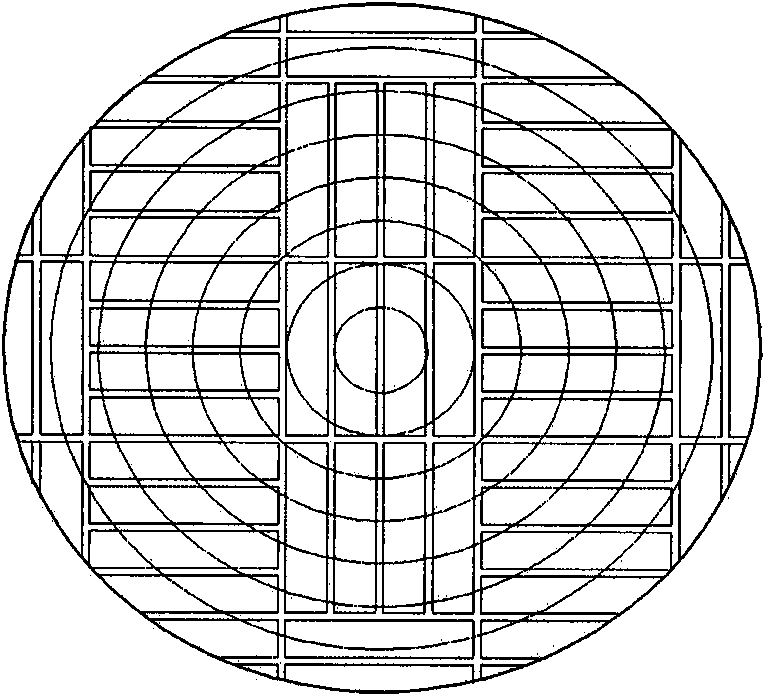

[0015] figure 2 Saw the model for the ladder of the log. For the purpose of producing ordinary solid wood floor slabs, the cross-sectional specification of the slab is 100mm×22mm, and the sawing loss is set to 5mm. At the same time, in order to be suitable for the processing technology of trapezoidal downward sawing and circular sawing equipment, the maximum height of each sawing path shall not exceed the width of the board.

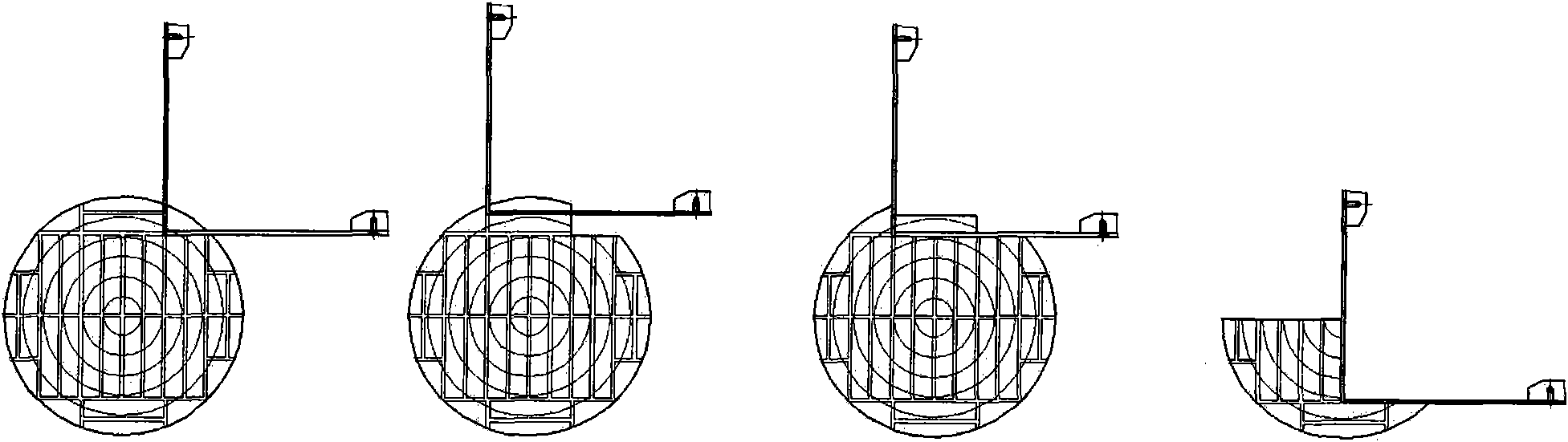

[0016] Duplex circular saw sawing process such as image 3 Shown: According to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com