Synthetic rubber material injecting machine and injecting device thereof

An injection device and synthetic rubber technology, which is applied in the field of synthetic rubber material molding equipment, can solve the problems of general products without suitable structure and inconvenience, and achieve the effects of shortening the production cycle, improving production efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The synthetic rubber material injection machine of the present invention is used for injection molding of granular synthetic rubber material. The granular synthetic rubber material does not undergo self-vulcanization at a temperature lower than 80°C, and can be stored at a temperature of 30°C for a long time without low temperature storage. For the specific content of the granular synthetic rubber material, please refer to the application titled "crosslinkable rubber composition, its use, rubber particles made by it, and the preparation method of the rubber particle" filed by the applicant on June 26, 2009. and injection method” Chinese invention patent application.

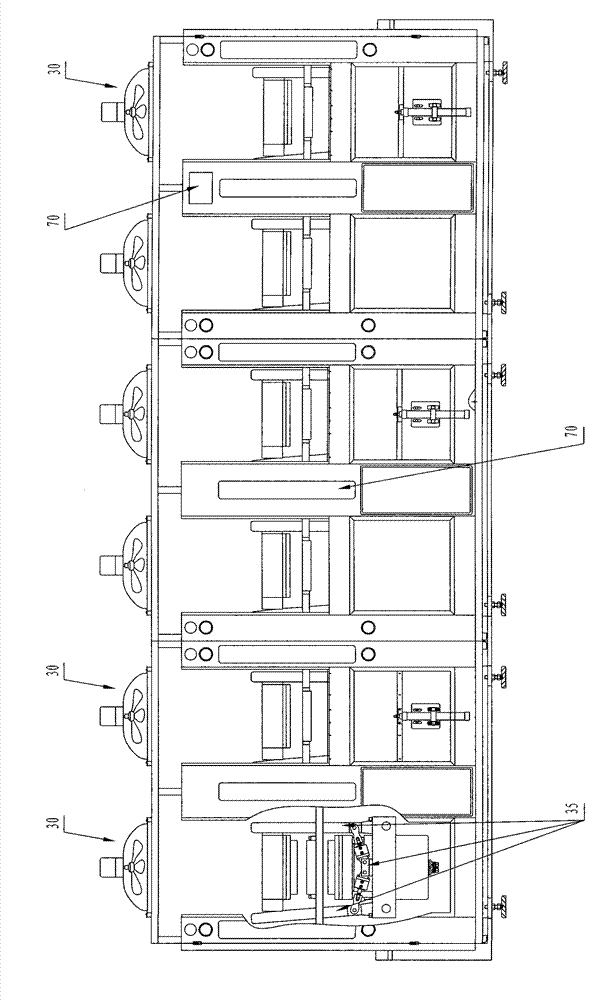

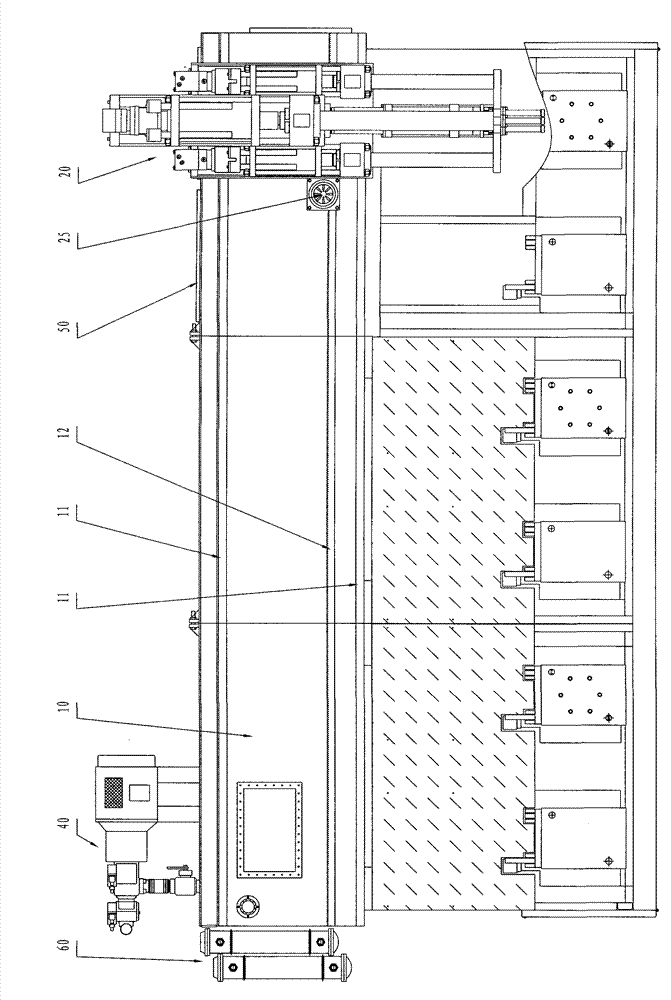

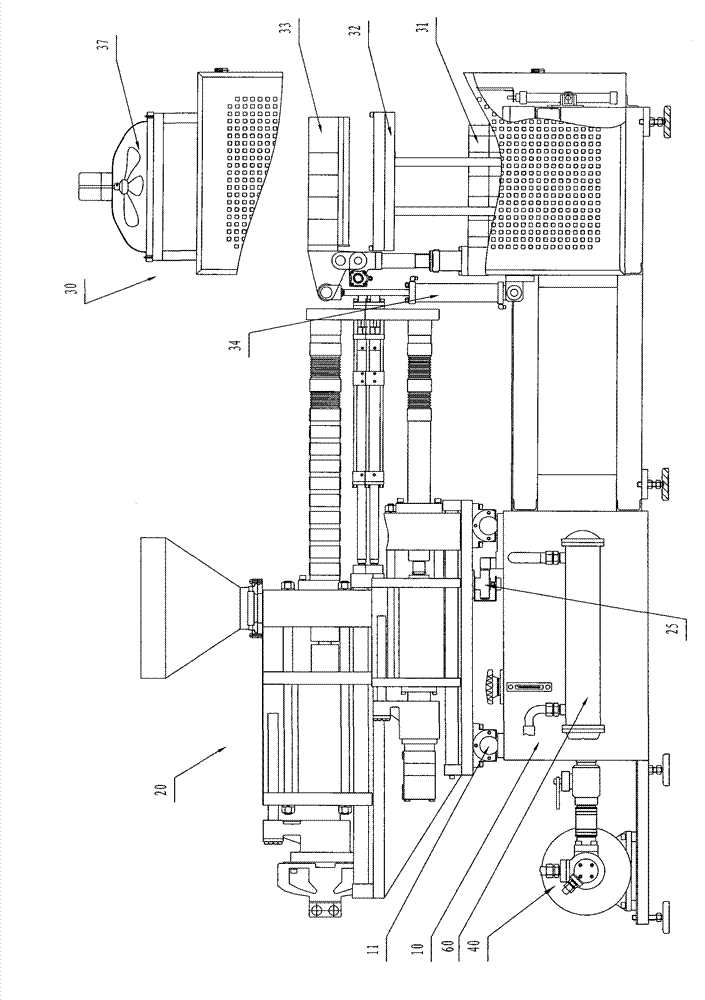

[0031] see Figure 1 to Figure 3 , are respectively the front view of the main structure, the top view of the main structure and the left view of the main structure of the preferred embodiment of the synthetic rubber material injection machine of the present invention. The synthetic rubber material injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com