Connection liner structure of twist beam-type rear suspension

A rear suspension and torsion beam technology, applied in the field of automobile rear suspension system, can solve the problems of high rigidity and can not meet the handling stability performance and smoothness at the same time, and achieve the effect of small rubber rigidity and improved torsional rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

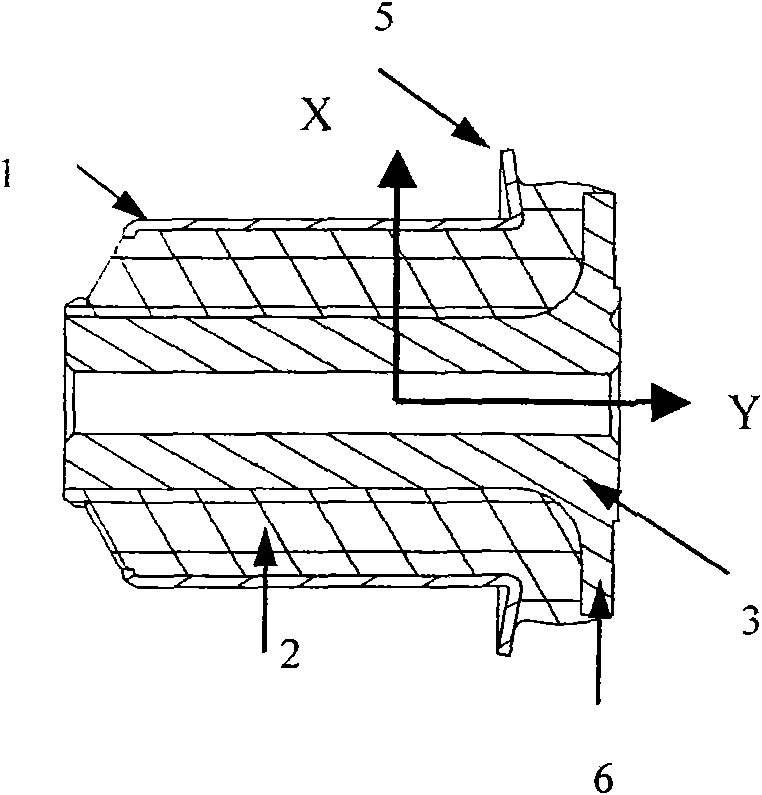

[0015] see image 3 , Figure 4 , The torsion beam type rear suspension connection bushing is composed of an inner lining pipe 3, an outer lining pipe 1, a rubber material 2 and a plane rubber washer 4. Among them, the outer liner 1 is set outside the inner liner 3, and the axial annular space between the two liners is filled and bonded with rubber material 2, that is, the rubber material 2 has no flanging, and its length is limited to the inside Between the liner 3 and the cylindrical surface of the outer liner 1. And between the inner liner flange 6 and the outer liner flange 5, a flat rubber washer 4 is set. Then reserve gap between the inner sides of 6.

[0016] When installing, after the bushing is installed on the base through bolts, the flange plate of the inner liner is on the inner side of the base, and a small gap is maintained between the inner side of the flange plate of the inner liner and the rubber pad, and the outer side of the flange plate of the inner line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com