Improved manufacturing method for knit goods

A manufacturing method and technology for knitted goods, applied in textile and papermaking, knitting, weft knitting and other directions, can solve the problems of excessively thick knitted fabrics, loss of elasticity of clothing, inability to transform artistic paintings into knitted clothing, etc., and shorten the time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

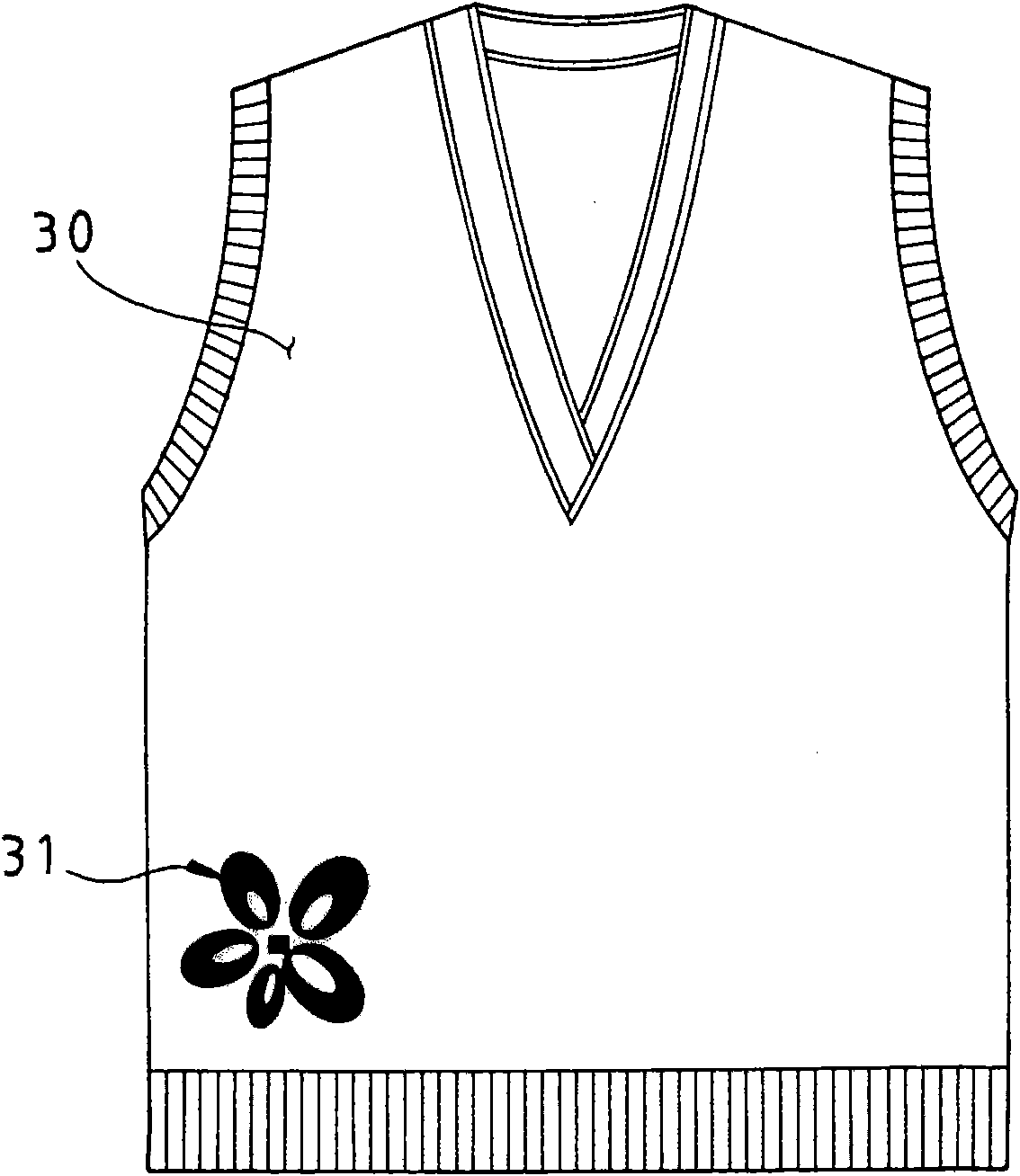

[0071] In order to enable the examiner to understand the characteristics of the manufacturing method and the connotation of the invention in detail, a preferred embodiment of the invention is given hereby, accompanied by a detailed description of the manufacturing flow chart, so that the advantages of the invention can be more clearly understood.

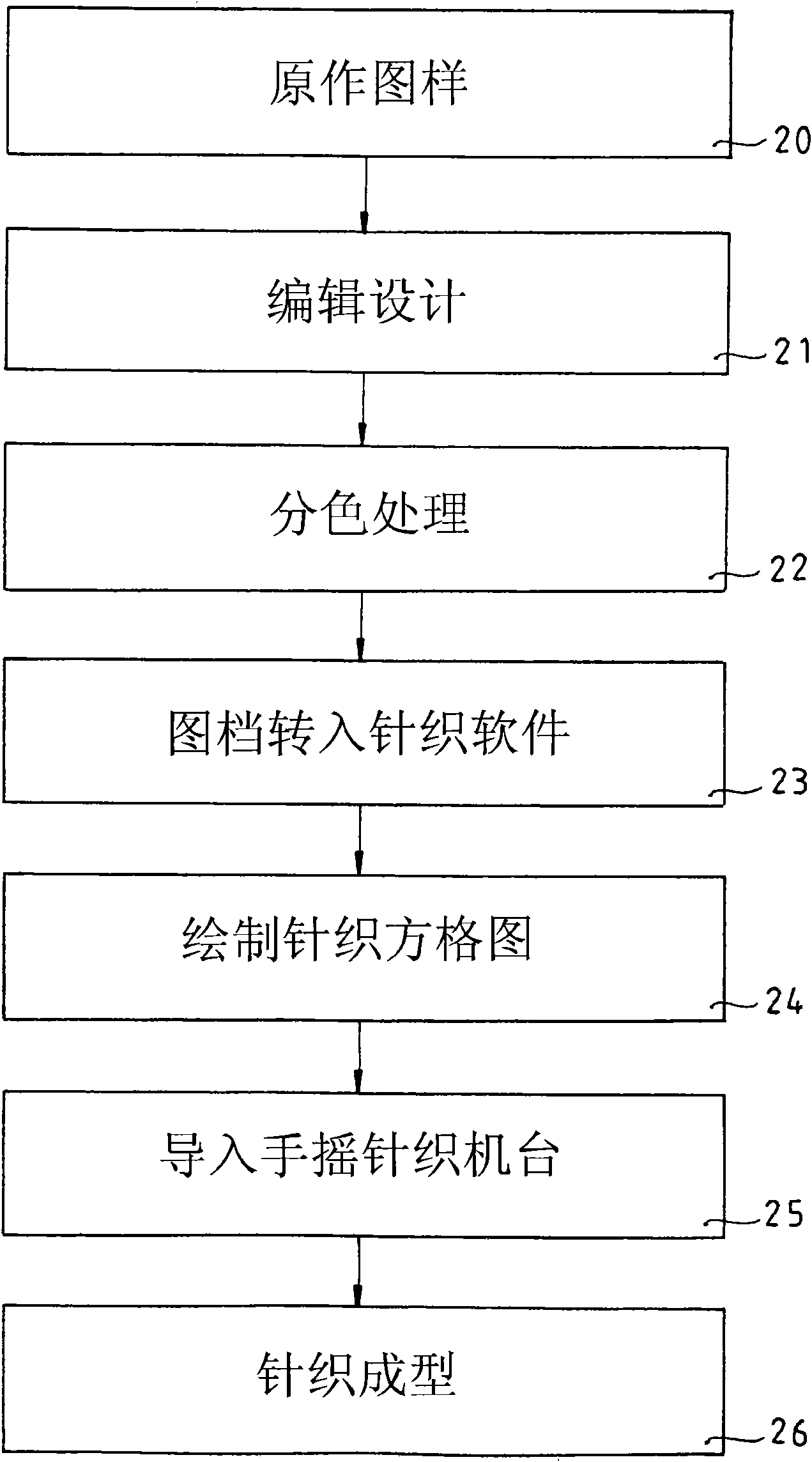

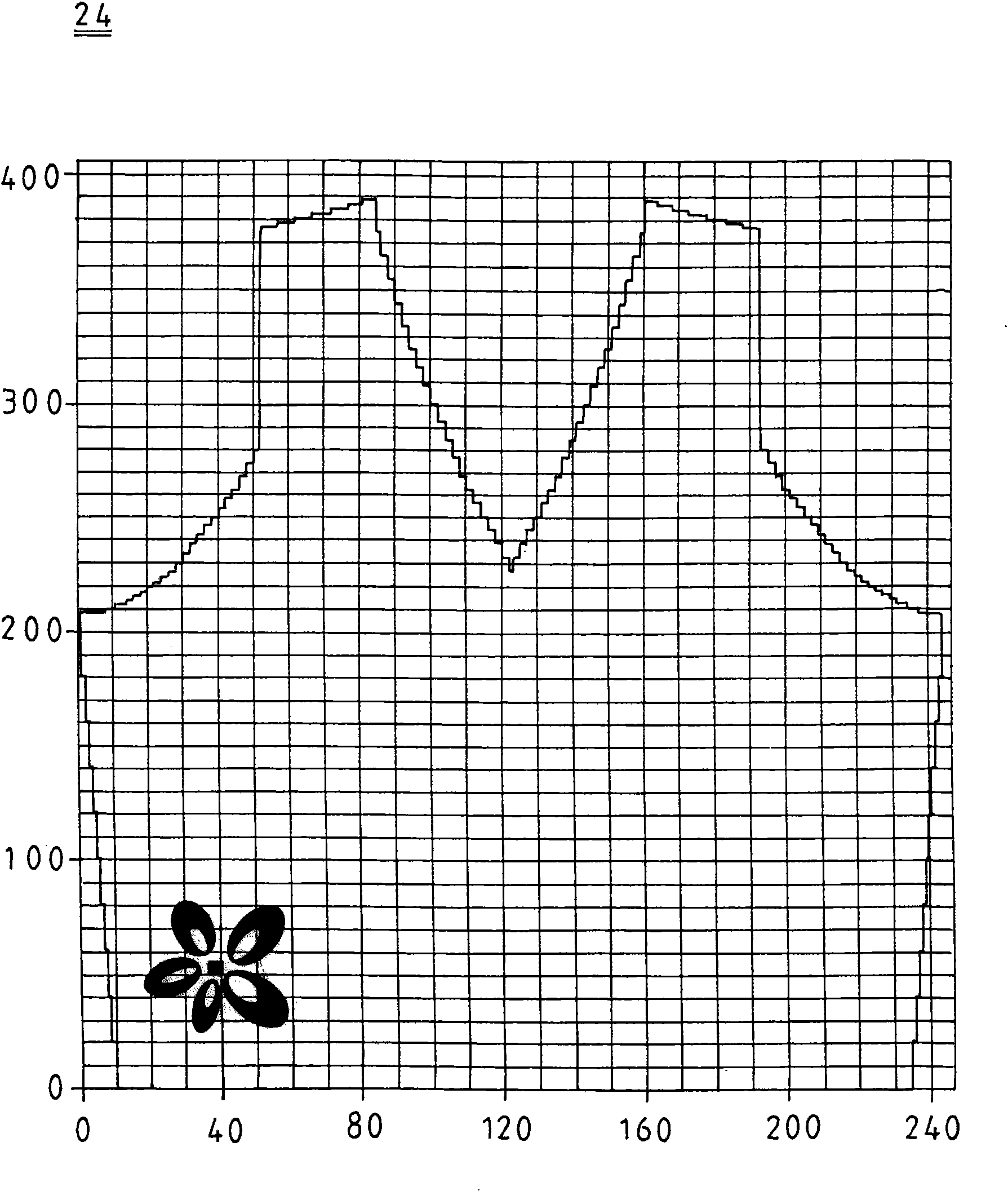

[0072] First, see figure 1 Shown, the improved manufacturing method of knitwear of the present invention comprises the following steps:

[0073] The original drawing 20 is input into a computer for image digitization. The original pattern 20 can be a designer's simple manuscript pattern, or a famous painting with a long history, or even a photo, all of which can be the material of the original pattern 20 of the present invention.

[0074] Disassemble the digitized original pattern 20, and re-edit the design 21 on the knitwear.

[0075] The edited design 21 can be completely copied from the original design 20 according to the actua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com