Bidirectional final motion test fixture and bidirectional final motion test method thereof

A test fixture and fixture technology, which is applied in the application of repetitive force/pulsation force to test the strength of materials, test wear resistance, measuring devices, etc., can solve problems such as coating life evaluation, and achieve the effect of small error and accurate displacement measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

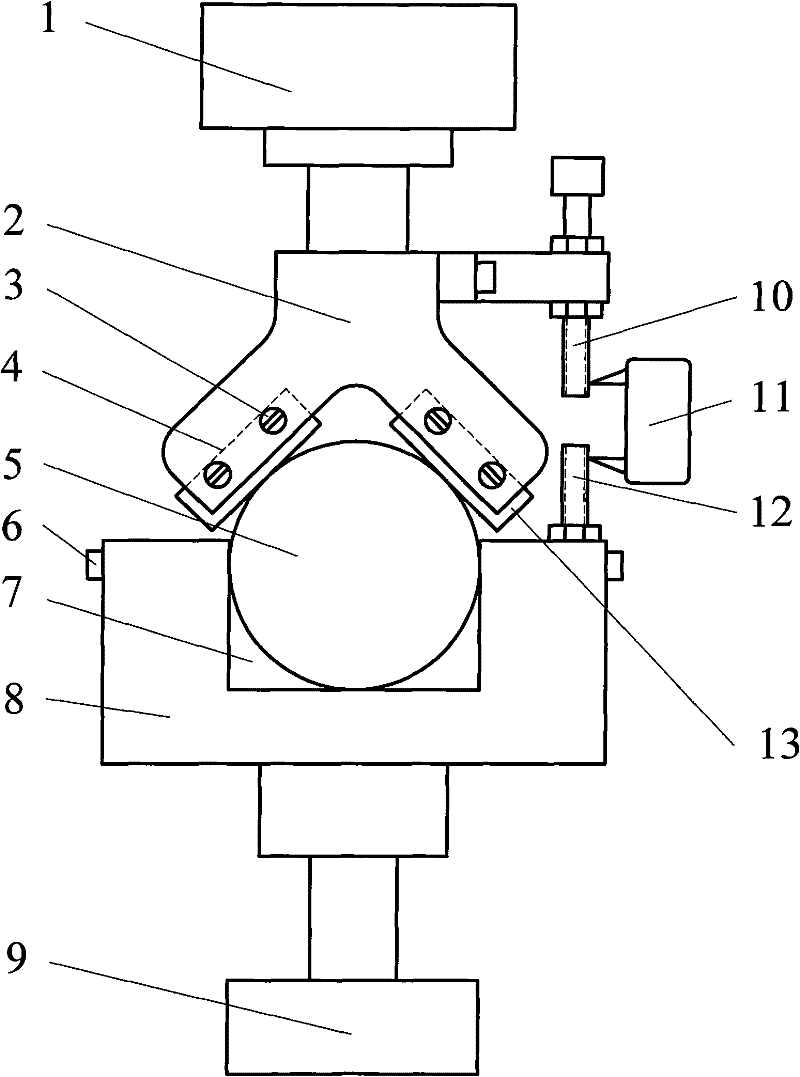

[0038] figure 1 As shown, the first specific embodiment of the present invention is a two-way micro-motion test fixture, including: a plane specimen fixture 2 threaded to the lower part of the load sensor 1 under the beam of the hydraulic servo micro-motion test bench, and a hydraulic servo micro-motion test fixture 2. The ball specimen fixture 8 that is threaded on the piston 9 of the hydraulic cylinder of the test bench. in:

[0039] The plane test piece fixture 2 is in the shape of a "herringbone", and the opposite surfaces on the left and right sides of the bottom of the plane test piece fixture 2 are provided with grooves 4 that are compatible with the plane test piece 13, and on the walls of the groove 4 are provided The screw 3 of the tight plane test piece 13;

[0040] The ball test piece fixture 8 is provided with the ball test piece cavity 7 that is compatible with the ball test piece 5, and the wall of the ball test piece cavity 7 is provided with a screw 6 for t...

Embodiment 2

[0051] The bidirectional fretting test fixture of this embodiment is exactly the same as that of Embodiment 1.

[0052] Its experimental method is also basically the same as Example 1, and the difference is only the following two operations:

[0053] A. Test piece installation: place two plane test pieces 13 in the grooves on both sides of the plane test piece fixture 2 .

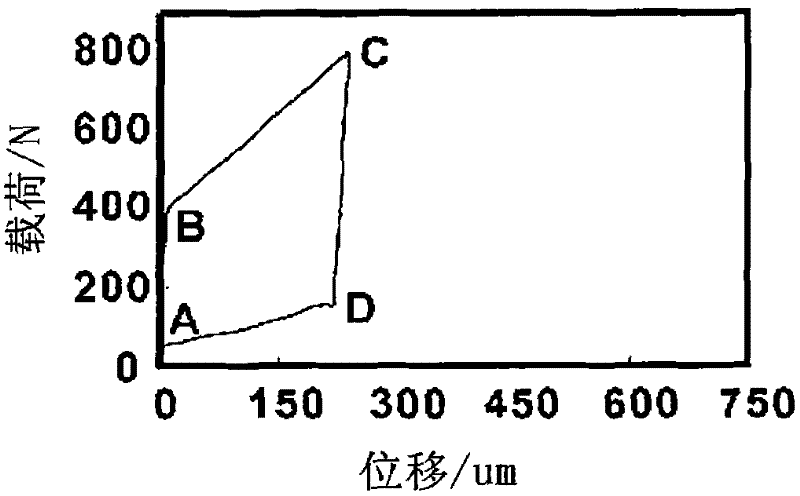

[0054] D. Micro-motion experiment: the load sensor 1 data is cleared, the computer measurement and control system controls the piston 9 to move the ball specimen fixture 8 upward according to the set loading speed, and applies a load to the plane specimen 13, so that the ball specimen 5 is pressed into the plane The test piece 13 reaches the set depth; then the piston 9 reciprocates up and down with the set displacement amplitude centered on the position of the depth, and the displacement amplitude is less than twice the set depth value; the piston 9 reciprocates to The set number of cycles; while the pist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com