Household appliance service environment simulation device

A service environment and simulation device technology, applied to measuring devices, instruments, scientific instruments, etc., can solve problems such as unit failure, inability to evaluate the service life of the whole machine, and difficulty in adapting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

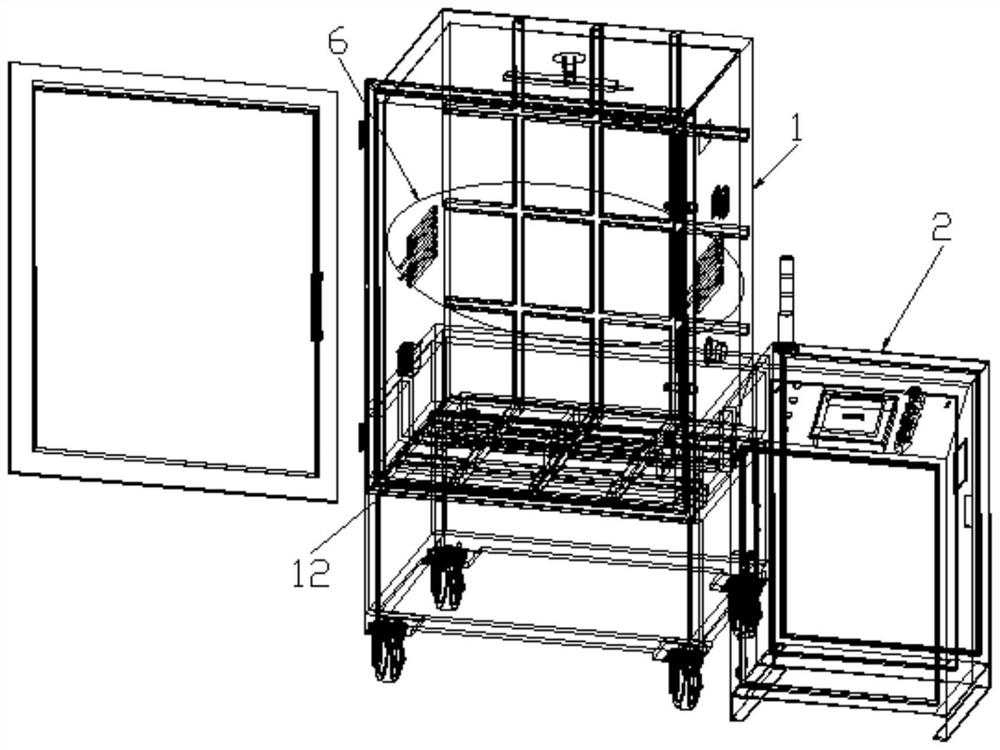

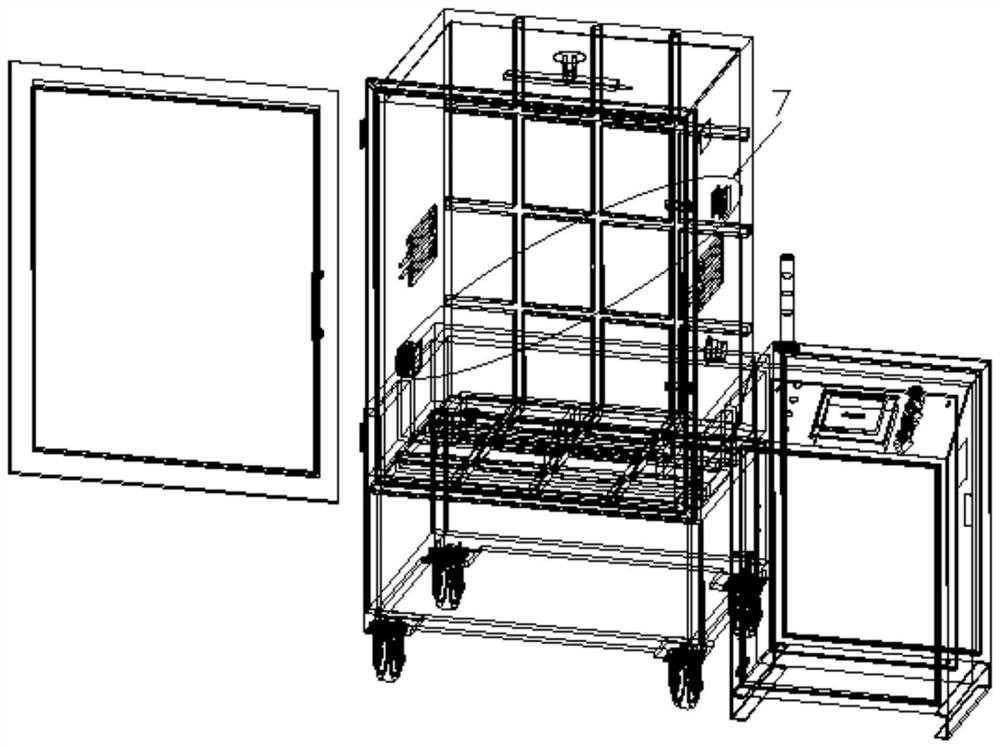

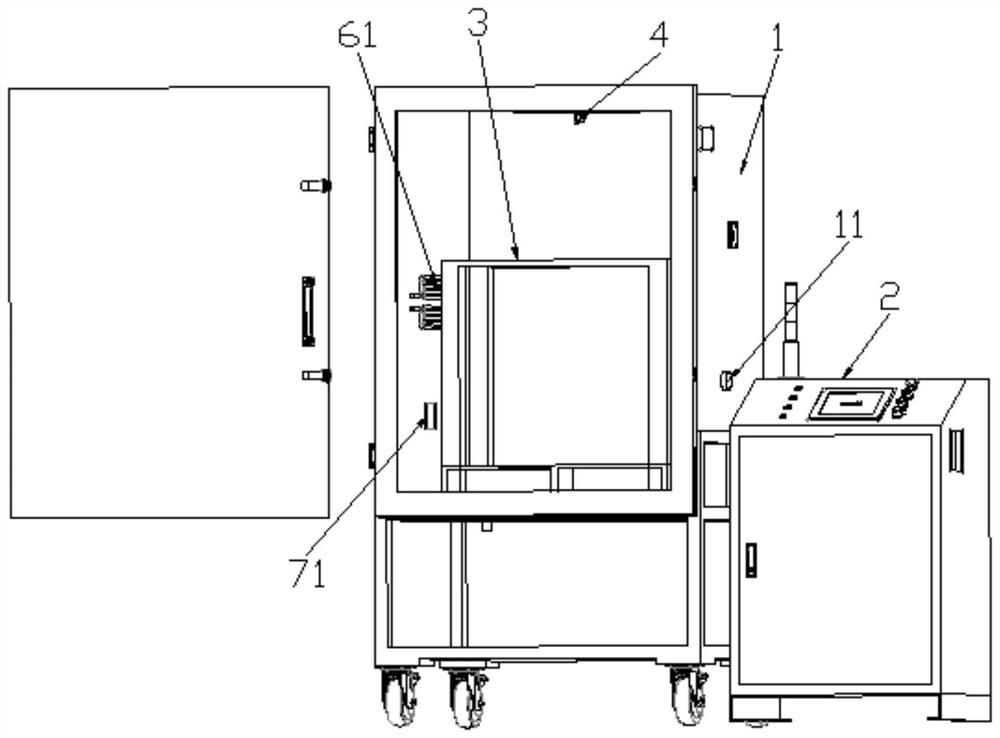

[0039] like Figure 1-Figure 5 As shown in the figure, this embodiment discloses a household appliance service environment simulation device, including a simulation box 1 and a control box 2. The inside of the simulation box 1 is provided with a spray mechanism 4, a heating mechanism 6, an illumination mechanism 5 and a ventilation mechanism. Mechanism 7, the spray mechanism 4 and the illumination mechanism 5 are both arranged above the interior of the simulation box 1, the spray mechanism 4 is connected with a corrosive medium storage box, and the heating mechanism 6 is installed inside the simulation box 1. On the side wall, the ventilation mechanism 7 is arranged on the side wall of the simulated box 1; the control box 2 is provided with a PLC controller, an operation panel, a display screen and a communication module, the spray mechanism 4, the heating mechanism 6. Both the lighting mechanism 5 and the ventilation mechanism 7 are connected to the PLC controller.

[0040] ...

Embodiment 2

[0054] This embodiment provides a household appliance service environment simulation device, which is different from the first embodiment in that:

[0055] Specifically, the bottom end of the simulation box 1 is provided with a rolling mechanism 14 , and the rolling mechanism 14 is provided with a roller 14 .

[0056] Specifically, the simulation box 1 includes a cabinet door 13 , one side of the cabinet door 13 is hinged with one side of the simulation box 1 , and the other side of the cabinet door 13 is connected to the other side of the simulation box 1 . Connect on the other side.

[0057] The other side of the simulation box 1 is provided with a limit buckle 101 , and the other side of the cabinet door is correspondingly provided with an elastic clip 131 , and the elastic clip 131 is connected with the limit buckle 101 .

[0058] Specifically, the bottom of the simulation box 1 is provided with a drain hole 12, and a circulation pipe is installed in the drain hole 12, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com