Cylinder type vertical transporting method, tool and system

A vertical transportation, cylinder-type technology, applied in transportation and packaging, lifting equipment in mines, etc., can solve the problems of high motor installation power, casualties, unsatisfactory energy-saving effects, etc., and achieve the effect of saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

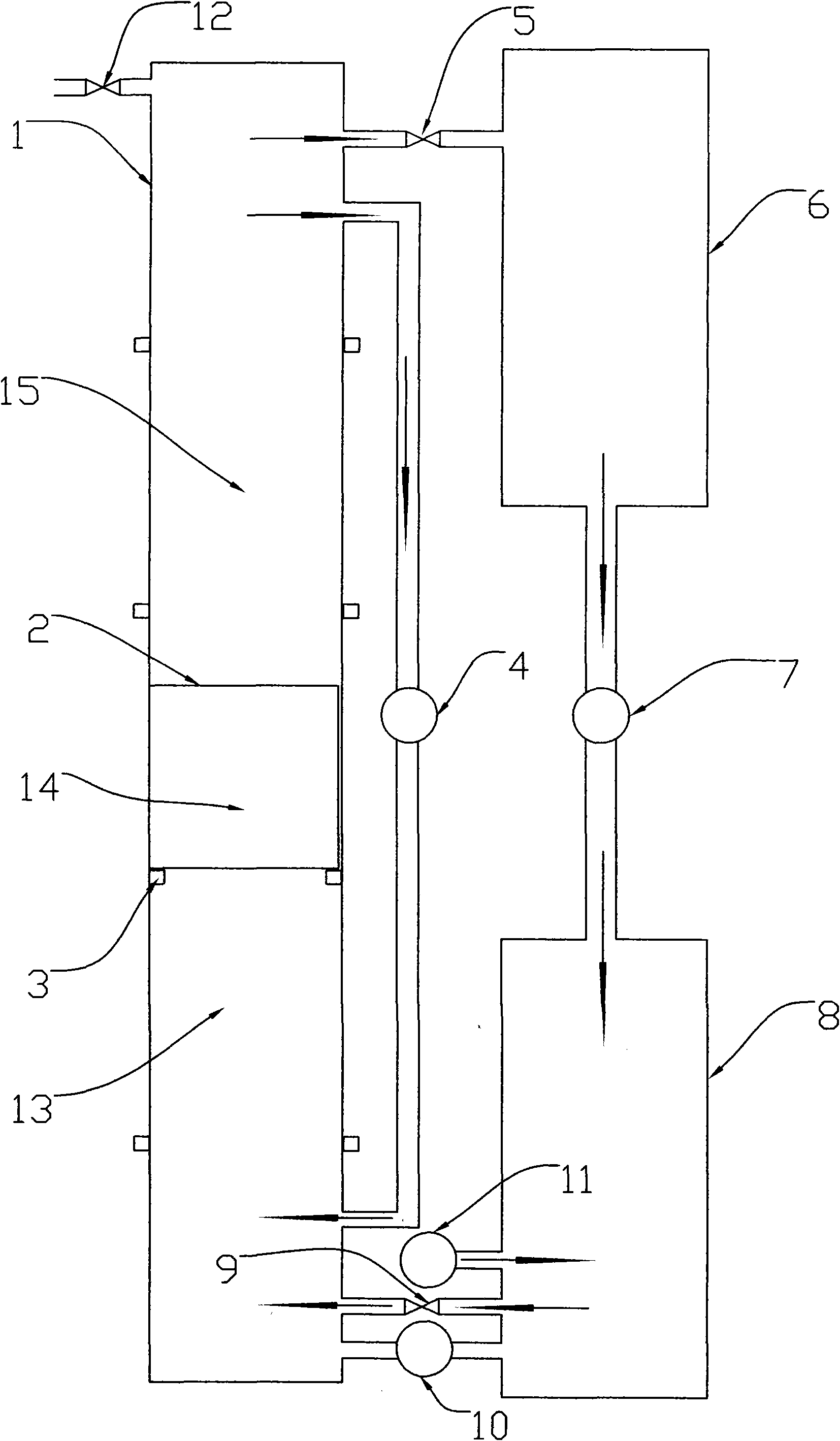

[0020] In the accompanying drawings, the large-diameter cylinder body is used as the shaft (1), the cylinder piston is used as the piston car (2), and the air pressure difference between the upper and lower sides of the car and the gravity of the car are used as the power to form a cylinder-type vertical transportation. Basic methods, tools and systems.

[0021] The upper and lower ends of the above-mentioned shaft (1) are closed, and the upper and lower ends of the piston car (2) are provided with sealing rings, which separate the space in the cylinder body into mutually sealed (13), (14) , (15) three paragraphs.

[0022] Adjust the piston car up and down by the blower fan (4), blower fan or / and air pump (7), vacuum tank (6) or / and air storage tank (8) and valves (5), (9), (12) The air pressure difference and stored energy in the closed space at both ends control the safe and stable operation and energy conversion of the piston car (2) up and down in the vertical shaft (1). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com