Swing type telescopic supporting leg device and container lateral face self loading and unloading transport cart

A telescopic outrigger and swing-type technology, which is applied in transportation and packaging, vehicle maintenance, lifting vehicle accessories, etc., can solve the problems of small outrigger span, poor vehicle stability, and large space occupation, and achieve site utilization High, flexible operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

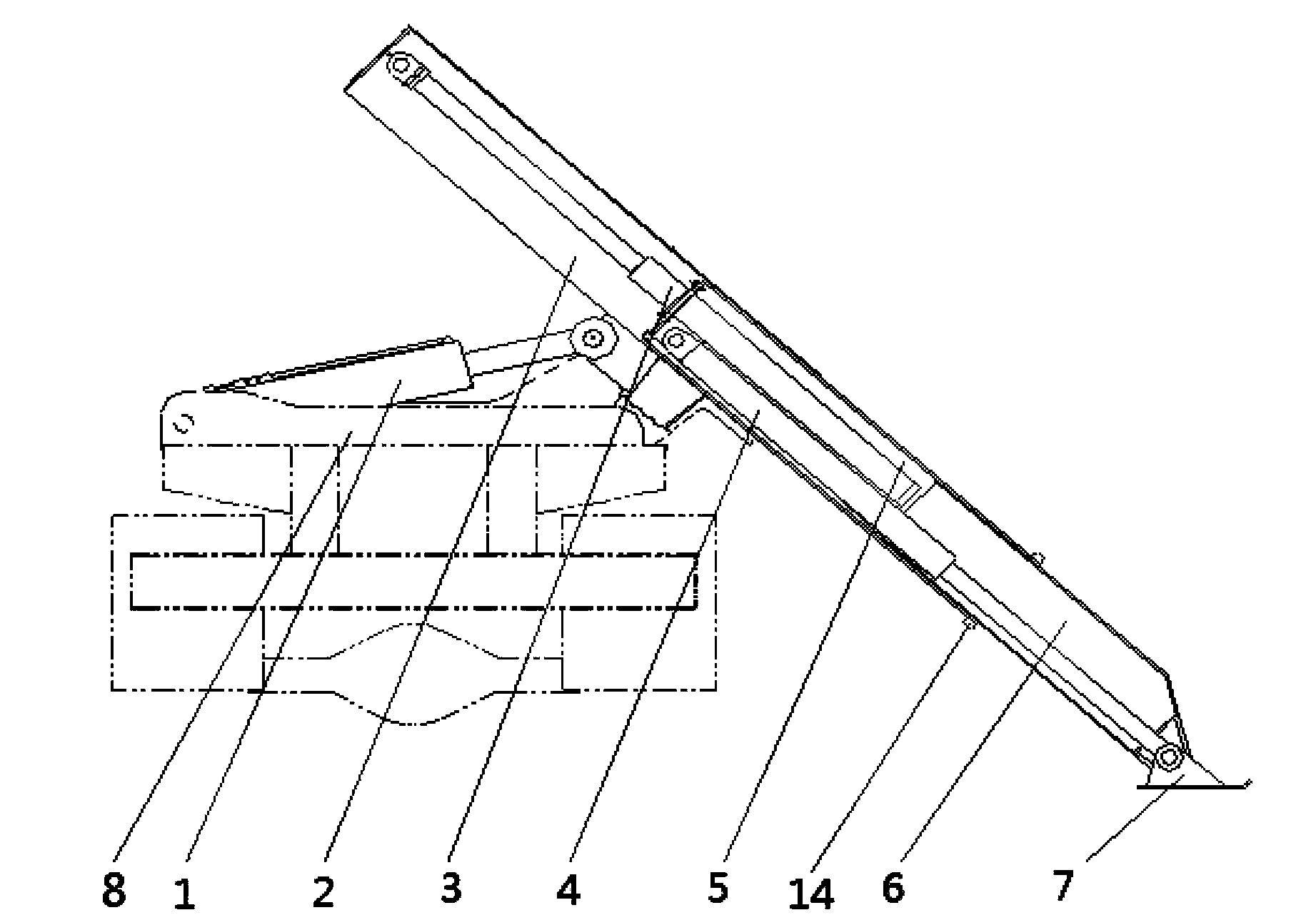

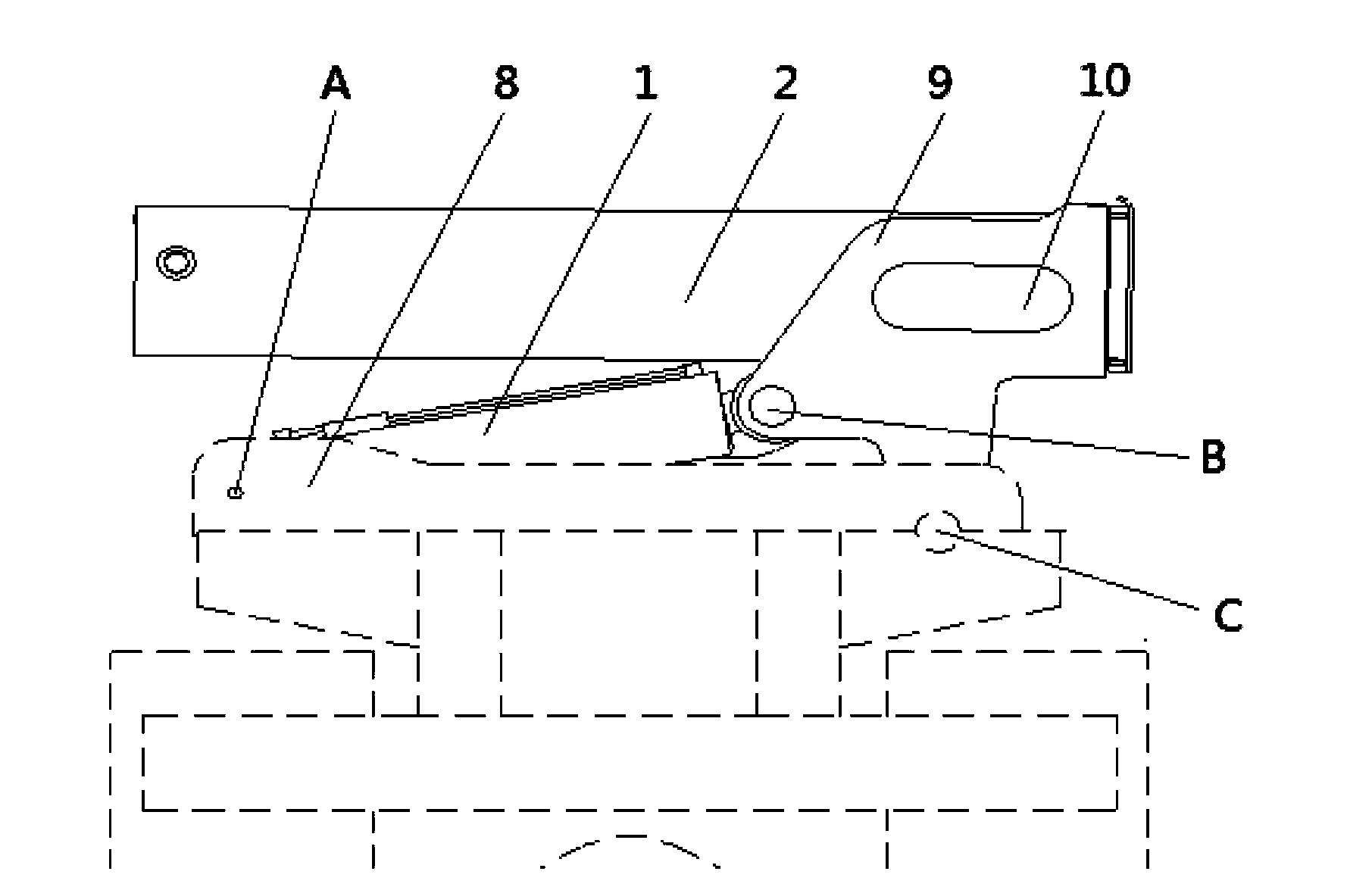

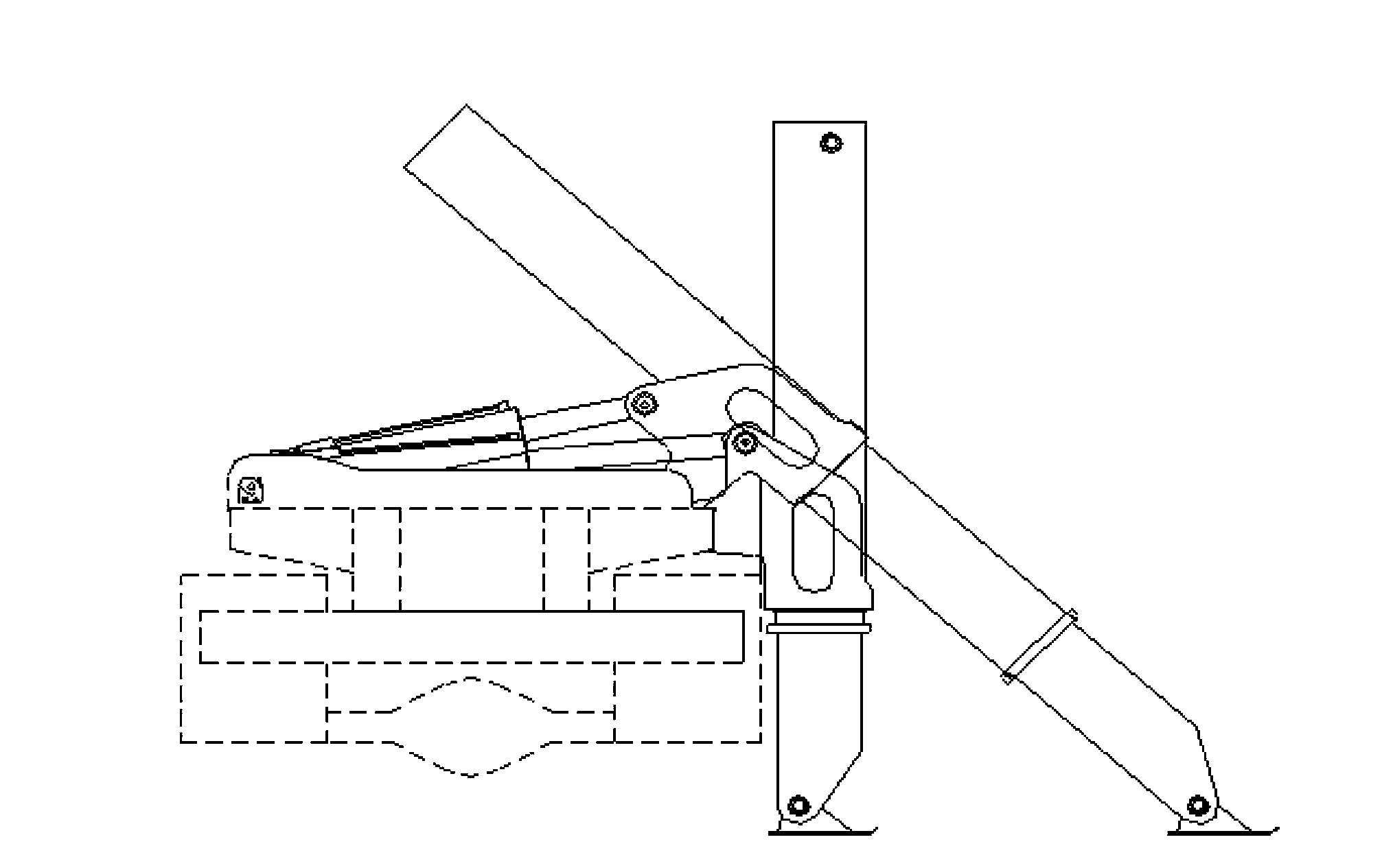

[0031] Such as figure 1 Shown is a schematic structural view of an embodiment of the swing-type telescopic outrigger device of the present invention. figure 1 In order to show the structure inside the telescopic outrigger, the part of the connecting plate is hidden, and the connection relationship of the connecting plate can be referred to figure 2 The collapsed state shown. The swing telescopic outrigger device in this embodiment includes luffing oil cylinder 1, swing outrigger 2, connecting plate 9, telescopic outrigger 5, 6, telescopic oil cylinder 3, 4 and movable leg 7, one end of luffing oil cylinder 1 and The connecting plates 9 are all hinged on the base 8, the other end of the luffing cylinder 1 is hinged on the connecting plate 9, the swing leg is fixed on the connecting plate 9, and the movable leg 7 is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com