Al-doped alpha-phase silicon nitride (alpha-Si3N4)-based material and preparation method thereof

A phase silicon nitride, -si3n4 technology, applied in the field of materials science, can solve very few problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] First, take 0.600g of finely ground silicon monoxide powder and 0.173g of aluminum powder and mix them evenly, put the mixed powder into the raw material area of the high-frequency graphite induction furnace, seal the quartz cover, and then vacuum. Subsequently, nitrogen gas was introduced into the furnace, and nitrogen gas with a flow rate of 800 ml / min was continuously introduced, and the furnace was maintained at an atmospheric pressure. Turn on the induction furnace, observe the temperature of the raw material area, control the temperature of the raw material area at 1620℃, the output power of the induction furnace is about 9kw, turn off the induction furnace after heating for 30 minutes, and maintain a constant flow of nitrogen throughout the reaction process. After cooling, open the quartz cover and take out the graphite furnace. Finally, a white reaction product was obtained in the deposition area at 1500°C when the graphite furnace was heated.

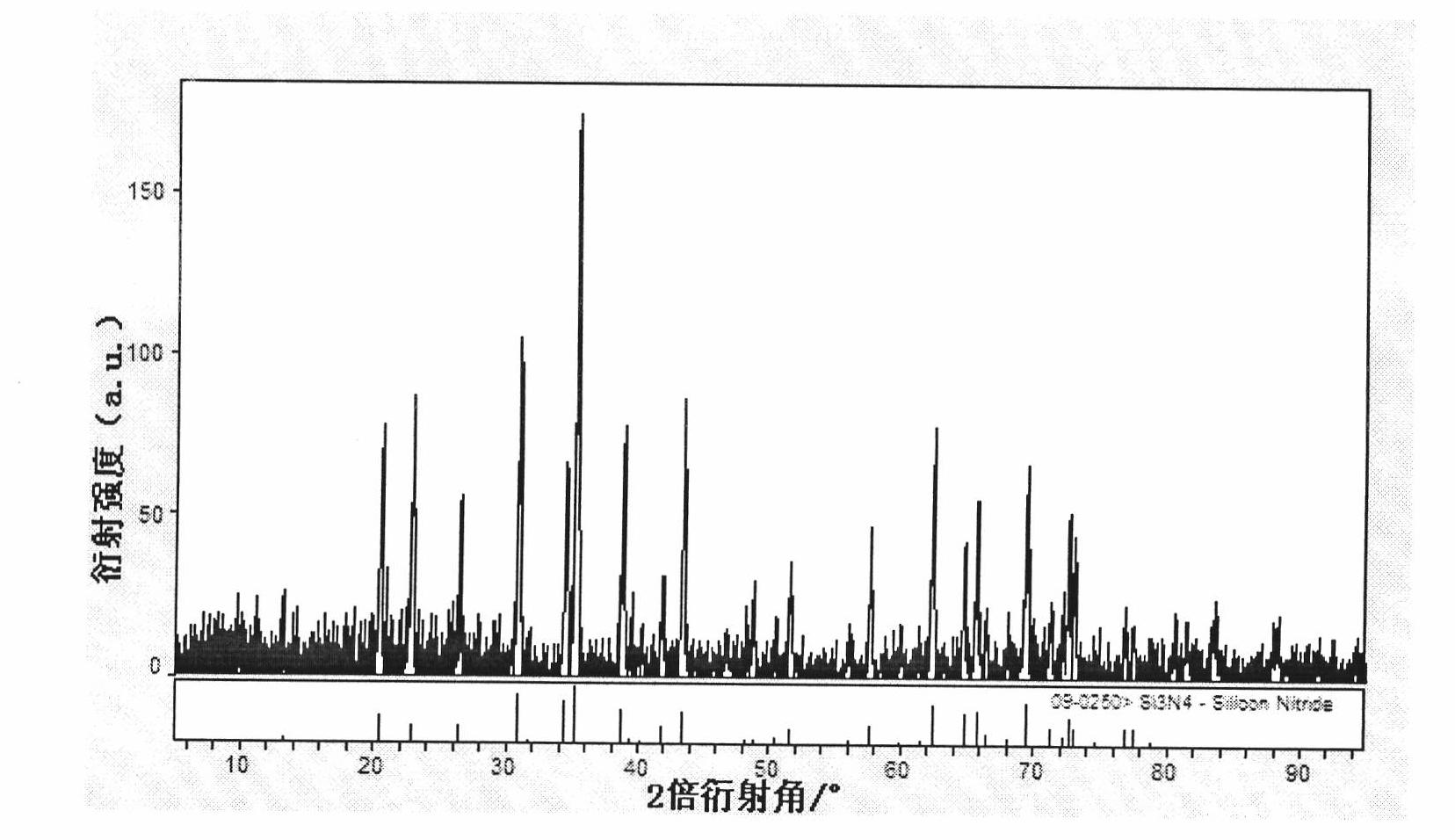

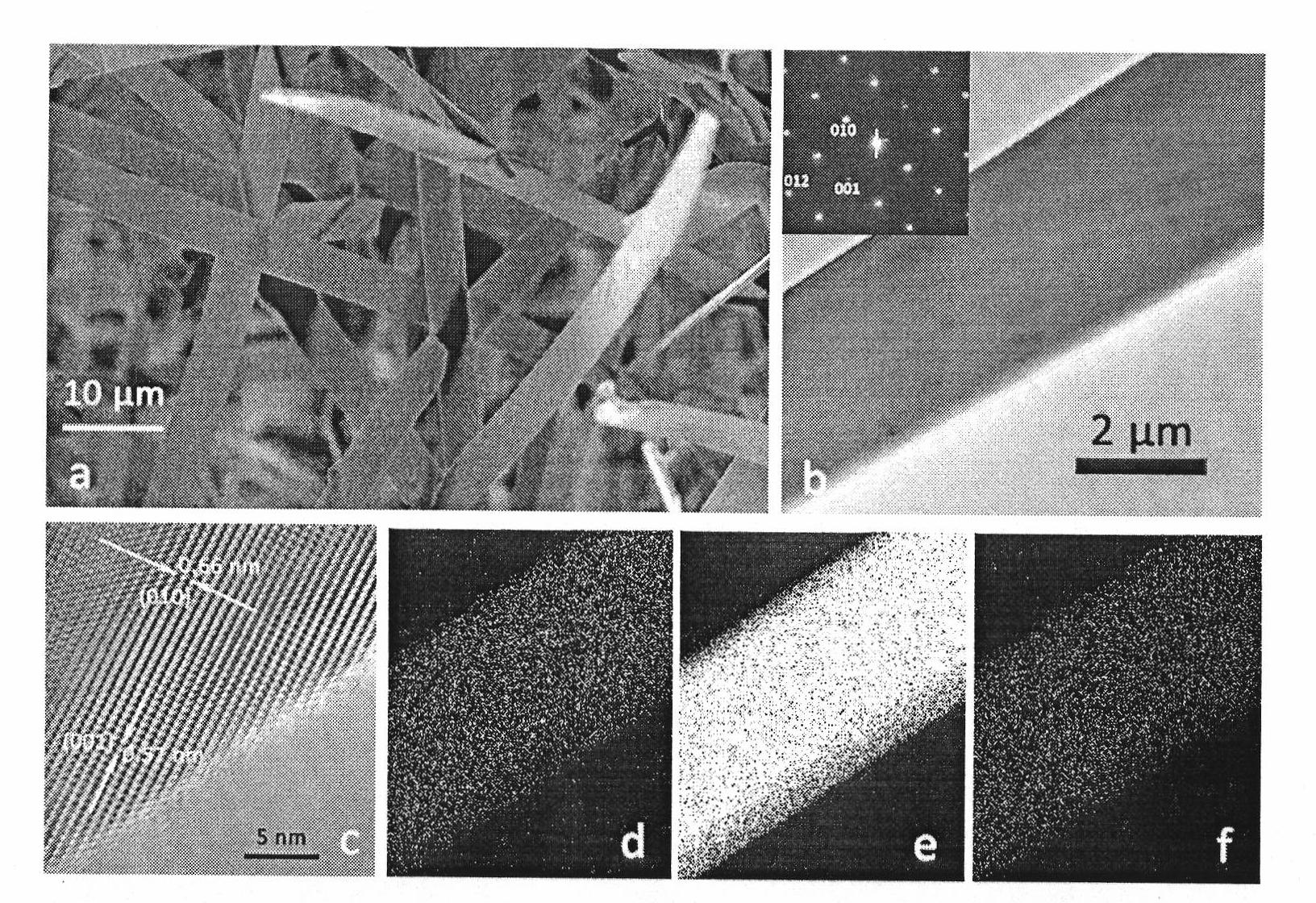

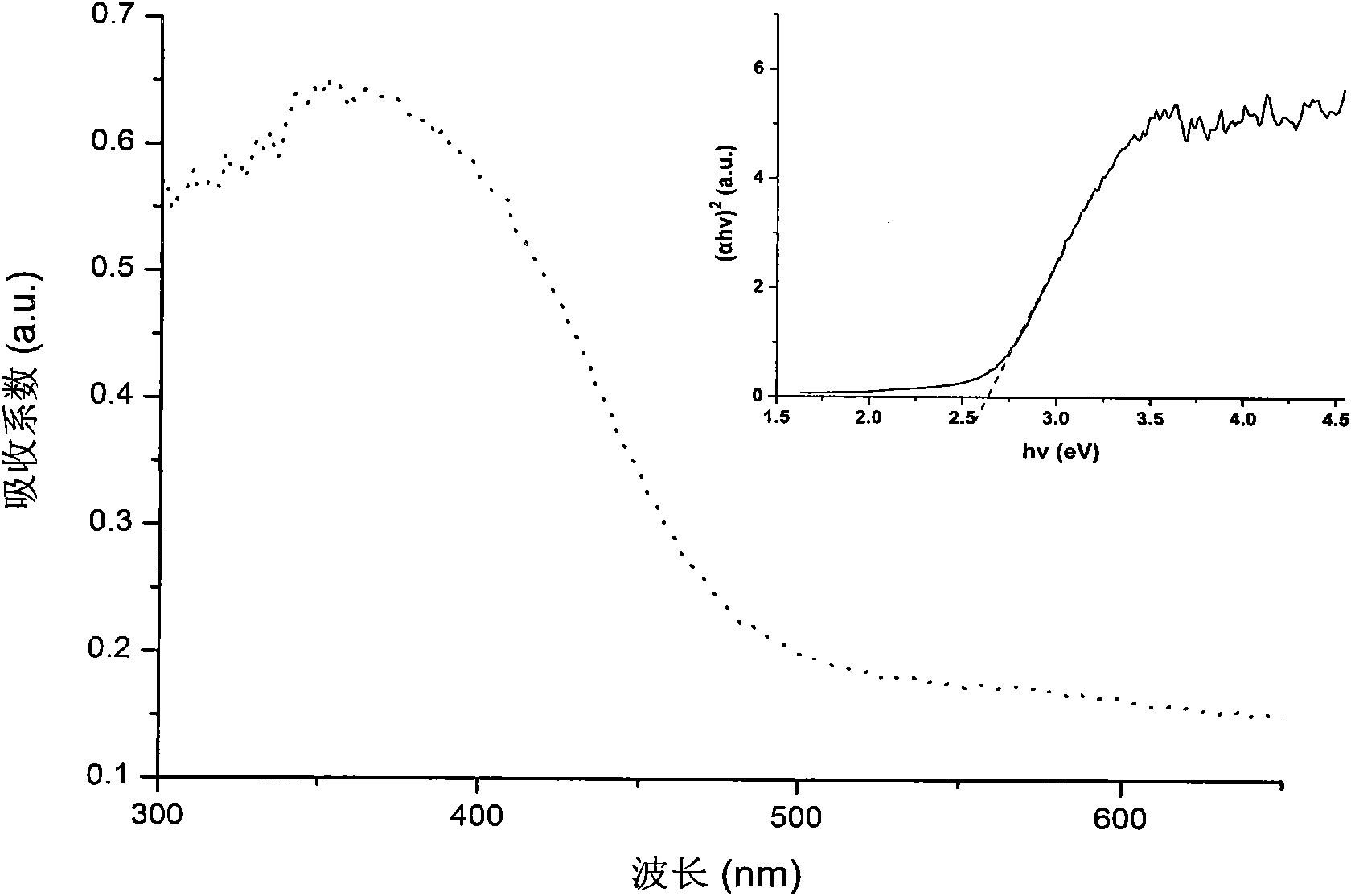

[0025] The resul...

Embodiment 2

[0027] First, take 0.600g of finely ground silicon monoxide powder and 0.173g of aluminum powder and mix them evenly, put the mixed powder into the raw material area of the high-frequency graphite induction furnace, seal the quartz cover, and then vacuum. Subsequently, nitrogen gas was introduced into the furnace, and nitrogen gas with a flow rate of 800 ml / min was continuously introduced, and the furnace was maintained at an atmospheric pressure. Turn on the induction furnace, observe the temperature of the raw material area, control the temperature of the raw material area at 1620℃, the output power of the induction furnace is about 9kw, turn off the induction furnace after heating for 60 minutes, and keep a constant flow of nitrogen throughout the reaction process. After cooling, open the quartz cover and take out the graphite furnace. Finally, a white reaction product was obtained in the deposition area at 1500°C when the graphite furnace was heated.

[0028] The resulting...

Embodiment 3

[0030] First, take 0.600g of finely ground silicon monoxide powder and 0.173g of aluminum powder and mix them evenly, put the mixed powder into the raw material area of the high-frequency graphite induction furnace, seal the quartz cover, and then vacuum. Subsequently, nitrogen gas was introduced into the furnace, and nitrogen gas with a flow rate of 800 ml / min was continuously introduced, and the furnace was maintained at an atmospheric pressure. Turn on the induction furnace, observe the temperature of the raw material area, control the temperature of the raw material area at 1620℃, the output power of the induction furnace is about 9kw, turn off the induction furnace after heating for 60 minutes, and keep a constant flow of nitrogen throughout the reaction process. After cooling, open the quartz cover and take out the graphite furnace. Finally, a white reaction product was obtained in the deposition area at 1300°C when the graphite furnace was heated.

[0031] The obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com