Remaining needle sleeve head forming machine

A technology of indwelling needles and molding machines, which is applied in the field of processing machinery for medical equipment, can solve problems such as low efficiency, high labor intensity of inspectors, and poor head taper effect, so as to improve molding efficiency, reduce inspection work intensity, and ensure molding effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

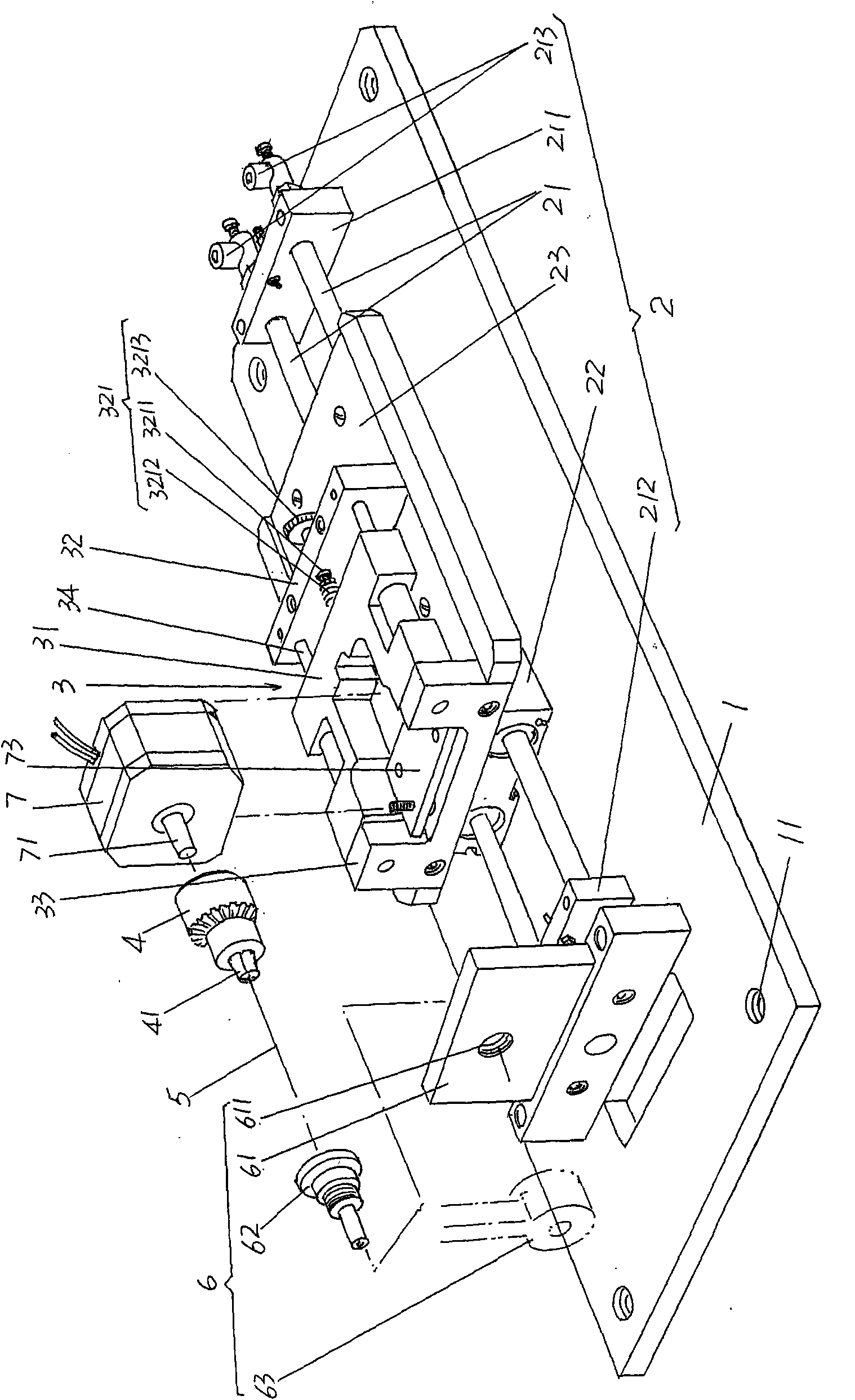

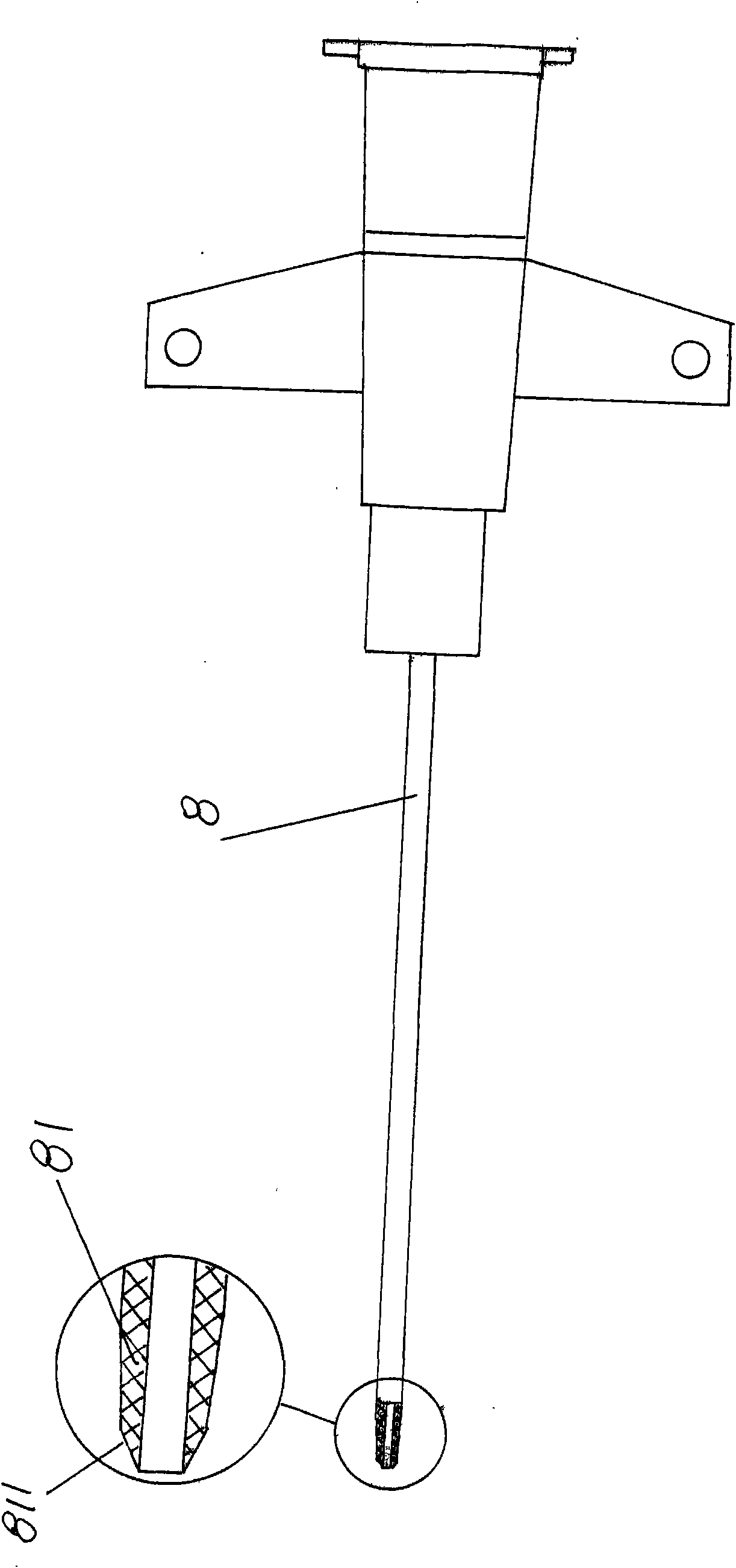

[0023] please see figure 1 , image 3 and Figure 4 , a rectangular base 1 that is a rectangle is provided, and when the present invention is in an applied state, the base 1 is fixed with a separately configured machine base through the screw holes 11 thereon. A fixture driving mechanism 2 is disposed on the base 1, preferably but not absolutely limited to the structure of the fixture driving mechanism 2 is as follows, a pair of air ducts 21 are parallel to each other, and one end of each is fixed on the first conduit seat 211, and each The other end is fixed on the second catheter adapter 212, the first and second catheter adapters 211, 212 are both fixed to the base 1, and the two keep corresponding. At one end of a pair of air ducts 21 figure 1 The right ends shown are respectively equipped with air inlet and outlet ports 213, and the pair of air inlet and outlet ports 213 are connected with an air source device by an air source pipeline, such as an air compressor or s...

Embodiment 2

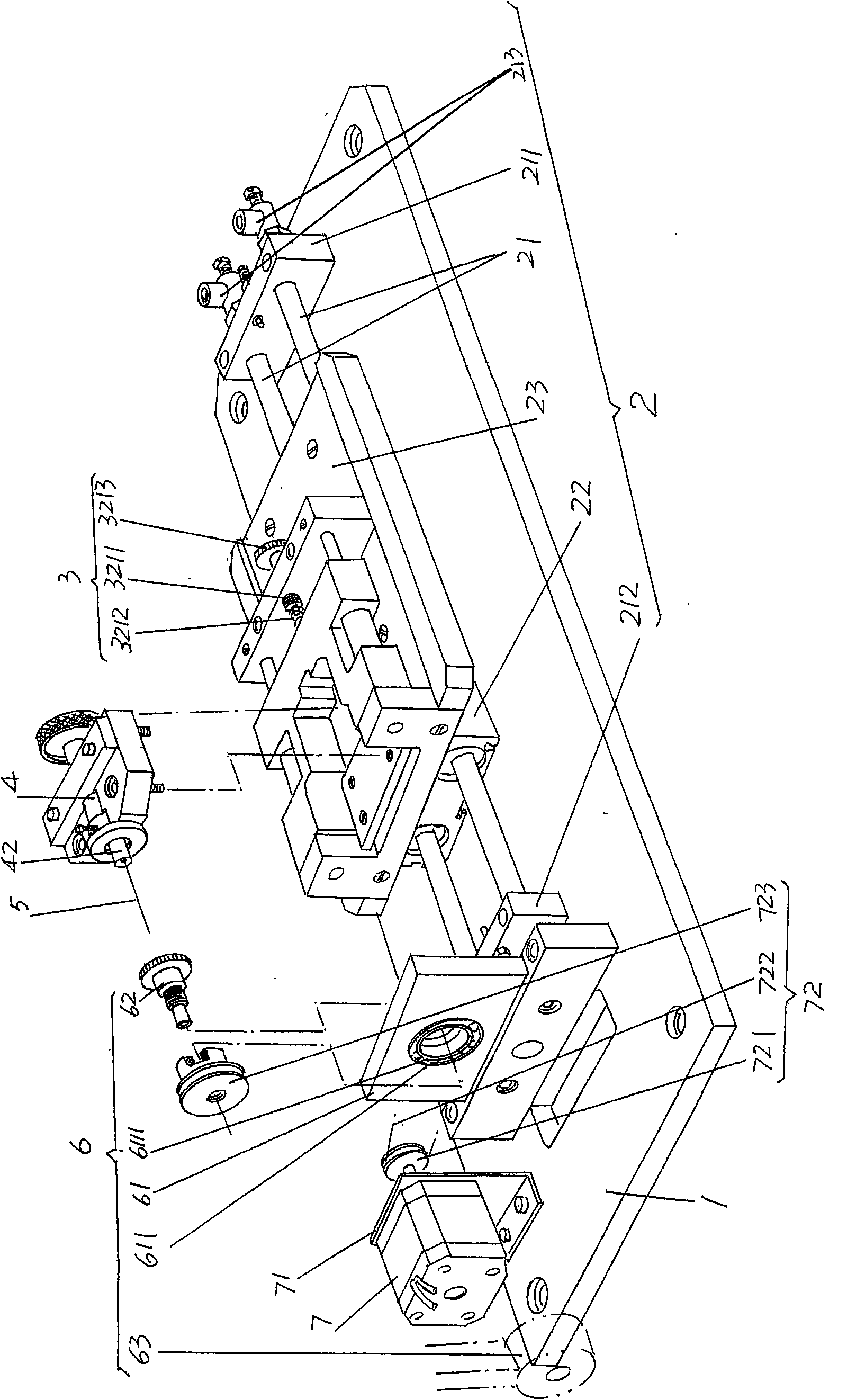

[0028] please see figure 2 , embodiment 1 is to make the mandrel 5 rotate, and the present embodiment is to make the mold 62 rotate, and the mandrel clamp 4 is directly installed on the movable seat body 31 of the clamp movable seat 3 (embodiment 1 is installed on the motor shaft of the motor 7 71, and the motor 7 is installed on the movable seat body 31), the mandrel 5 is fixed on the mandrel holder 42 of the mandrel clamp 4, and the mandrel holder 42 is equivalent to the three-jaw chuck 42 of embodiment 1. The bearing 6111 is arranged in the mold positioning hole 611 provided in the upper central part of the mold holder 61, and the motor 7 is fixed on the left end of the base 1 through an L-shaped support, and the power is transmitted to the aforementioned taper forming mechanism by the transmission device 72 The mold 62 of 6, that is, to make the mold 62 rotate, specifically: fix the first pulley 721 on the motor shaft 71 of the motor 7, fix the second pulley 723 in the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com