Digital twinning virtual inspection method for cement factory

A factory and digital technology, applied in the field of digital twin virtual inspections for cement factories, can solve the problems of long time-consuming manual inspections, missed inspections in manual inspections, and inability to complete inspections that should be inspected, so as to reduce inspection work. Quantity and ensure the accurate effect of inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

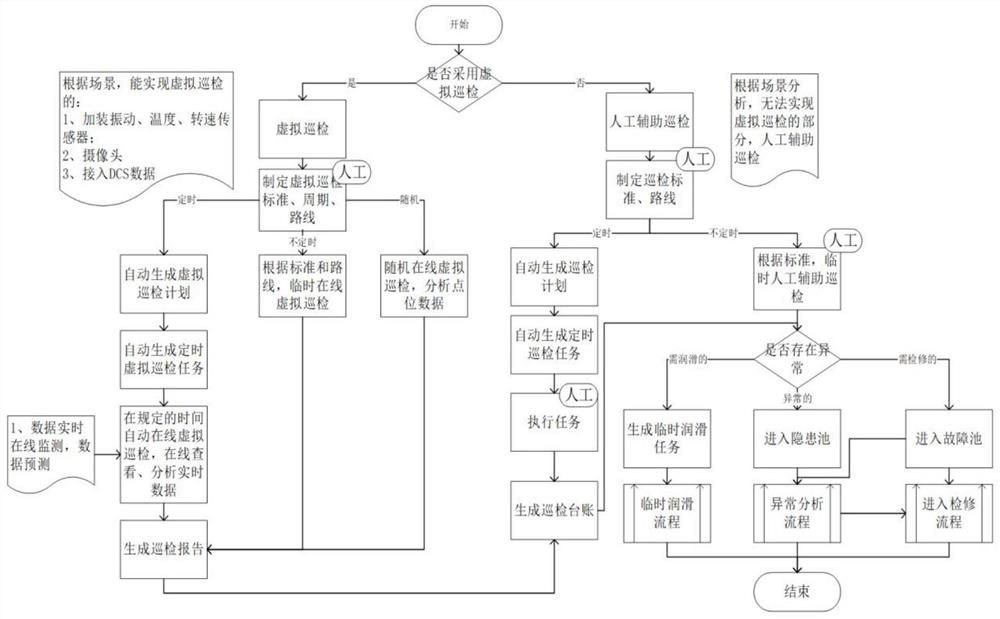

[0029] The technical solutions of the present invention will be further described below with reference to the accompanying drawings.

[0030] like figure 1 As shown in the figure, a virtual inspection method for cement factory digital twin includes the following steps:

[0031] (1) 3D modeling: Through 3D modeling software, build a virtual factory model in a 1:1 ratio. The virtual factory model contains data information required for inspection, including equipment name, equipment number, and equipment parameters. The 3D modeling software includes Revit, CAD, and 3Dmax. According to the characteristics of different specialties of the factory, some special software is usually used to achieve the consistency of the virtual factory and the physical factory shape. In order to realize virtual inspection, the 3D model should include inspection equipment, whose position is consistent with the position of the corresponding equipment in the physical factory; at the same time, in the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com