Preparation method of self-assembled superlattice materials of titanium dioxide nano rod

A technology of titanium dioxide and nanorods, applied in the fields of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc.

Inactive Publication Date: 2011-01-05

ZHEJIANG UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although Onsager's pioneering work and many subsequent theoretical simulations have predicted that a series of nano-superstructures can be formed through the self-assembly between one-dimensional anisotropic components, so far, there are still only a few successful reports in the literature. Through this self-assembled superlattice material, they are limited to nanorods of these 9 substances - BaCrO4, CdSe, CdS, CdSe / CdS, ZnO, CoO, Co, Au, Ag

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

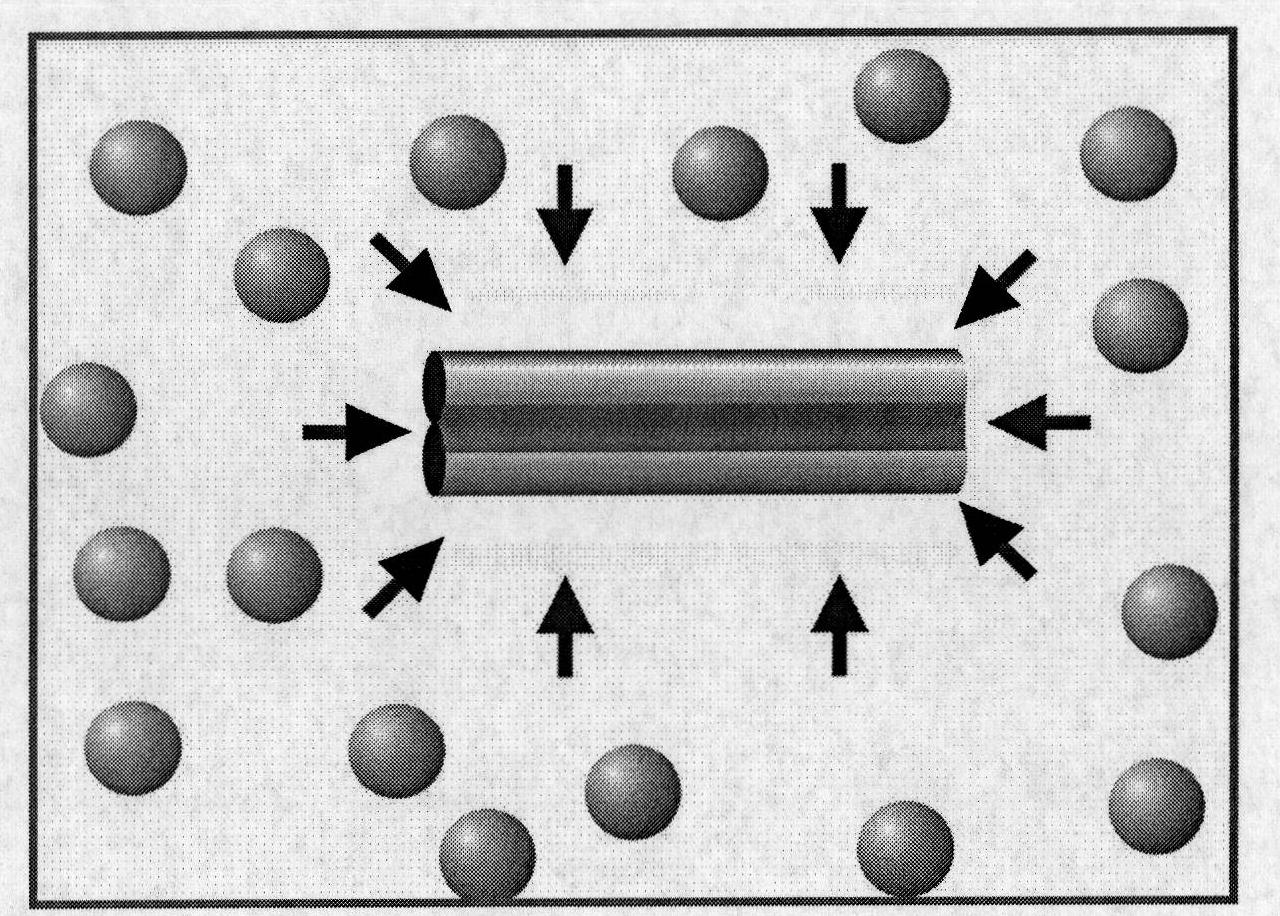

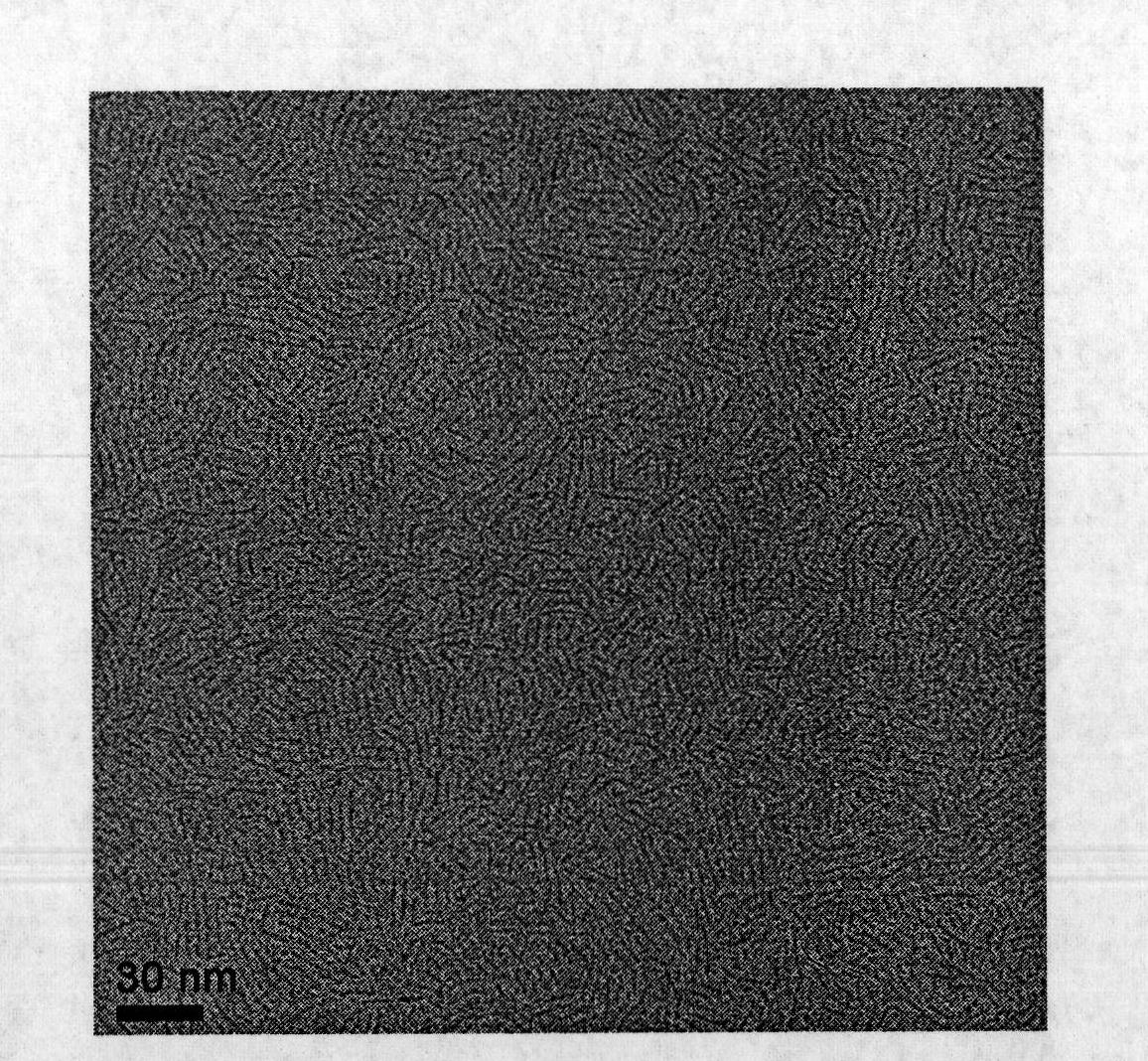

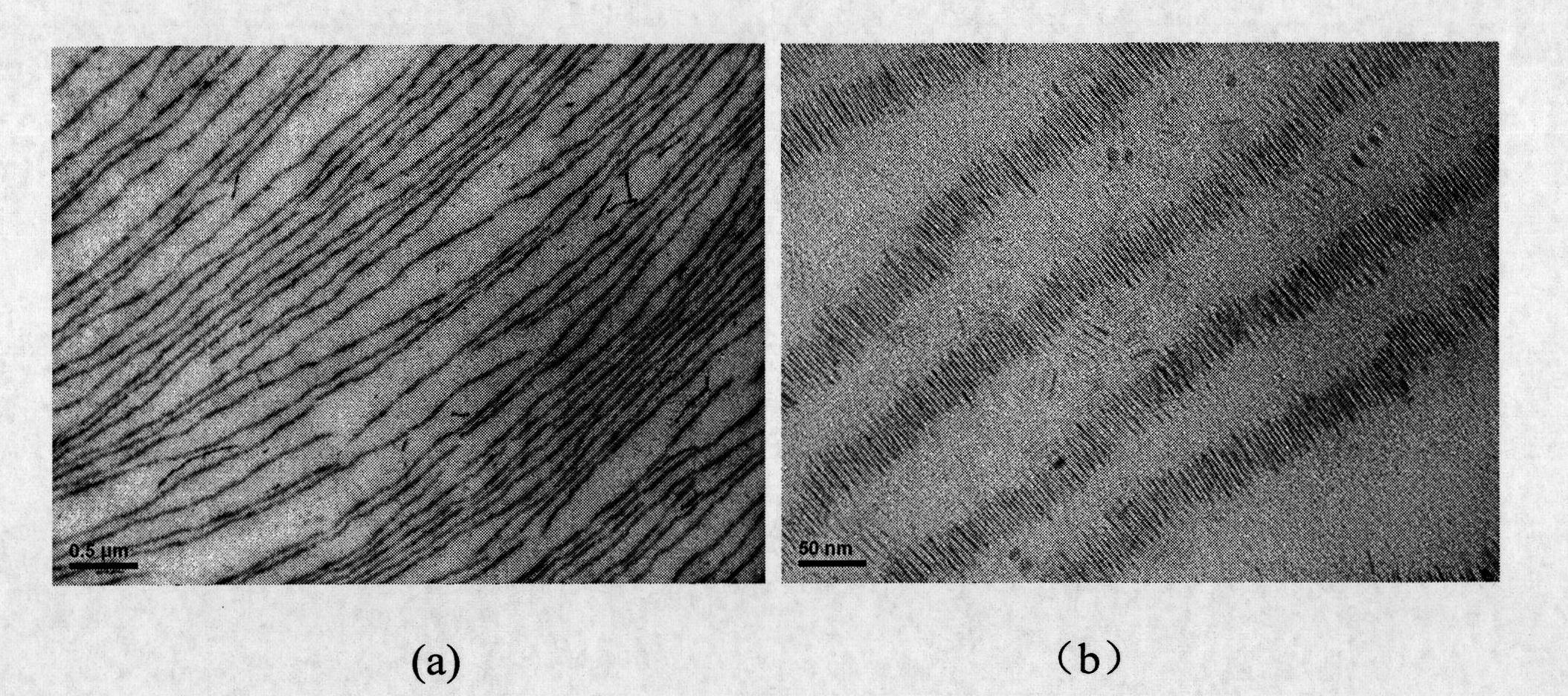

The invention discloses a preparation method of self-assembled superlattice materials of a titanium dioxide nano rod, comprising the following steps: (1) monodispersed TiO2 nano rods are synthetized, and the synthetic reaction is based on a condition that an unstable hydroxy derivative is produced by oleic acid titanium under nucleophillic attack of oil amide, the hydroxy derivative can be further polymerized to generate Ti-o-Ti, and produced TiO2 nano sticks are dispersed to a non-polar solvent to make clear TiO2 solution; (2) superfluous oil acid surface activators are added into the solution, and the superlattice materials with different structures (riband shapes and beehive shapes) are made by controlling the concentration of the oil acid in the solution and evaporating slow solvents.The invention has the advantages of firstly expanding the preparation scope of one-dimensional superlattice materials to the TiO2 nano rods of anatase, utilizing superfluous oil acid surface active agent to lead depletion attraction to adjacent TiO2 nano sticks, thereby adding macro-control factors for self-assembled drive force of the nano sticks so as to enable the self-assembled behavior to beeasily generated.

Description

Preparation method of titania nanorod self-assembled superlattice material technical field The invention relates to a preparation method of titanium dioxide nanorod self-assembled superlattice material. It utilizes the strategy of introducing depletion attraction force with excess surfactant to induce the self-assembly of TiO2 nanorods with uniform size to form superlattice materials with different structures. Background technique In the current nanocrystalline superlattice prepared by nanoparticles, its constituent units are mainly limited to spherical quantum dots, such as rare metals, semiconductors and magnetic quantum dots. This kind of quantum dot superlattice, in addition to maintaining the original characteristics of nanoparticles, has some special properties that nanoparticles do not have due to the coupling between quantum dots, and may be found in the fields of light, electricity, magnetism, etc. important application. A new trend in the preparation of nanocry...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C01G23/053B01F3/12

Inventor 王智宇叶波钱国栋樊先平

Owner ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com