Light guide bar with patterned surface to enhance light uniformity and intensity

A patterned surface, light uniformity technology, applied in the direction of light guide, optical fiber light guide, light guide of lighting system, etc., can solve the problems of increased light source cost, non-uniform luminosity, dim light, etc. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Preferred embodiments of the present invention are described in detail below, and accompanying drawings are used to illustrate examples thereof. And wherever possible, the same reference numbers are used in the drawings and descriptions to refer to the same or similar components.

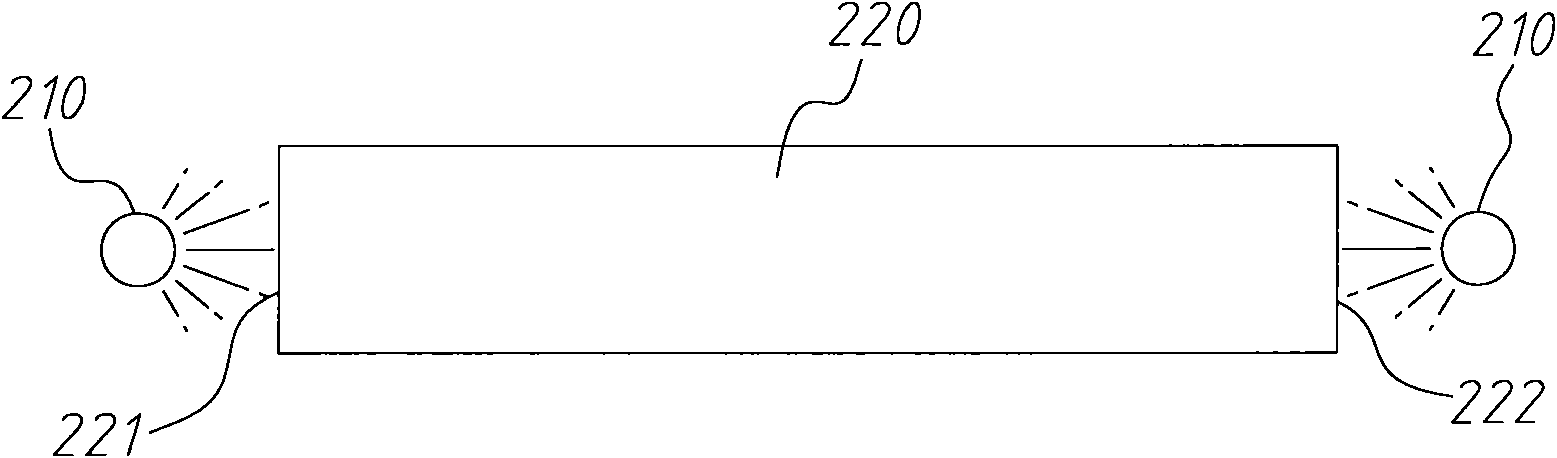

[0040] Figure 2A It is a schematic diagram of an embodiment of a flicker-free light source with a light guide column described in the present invention. The flicker-free light source includes an LED light source 210 placed at each end of the light guide bar 220 . The light guide column 220 is made of a transparent or semi-transparent, semi-hollow, hollow or solid cubic material. The light guiding column 220 further includes two ends 221 , 222 .

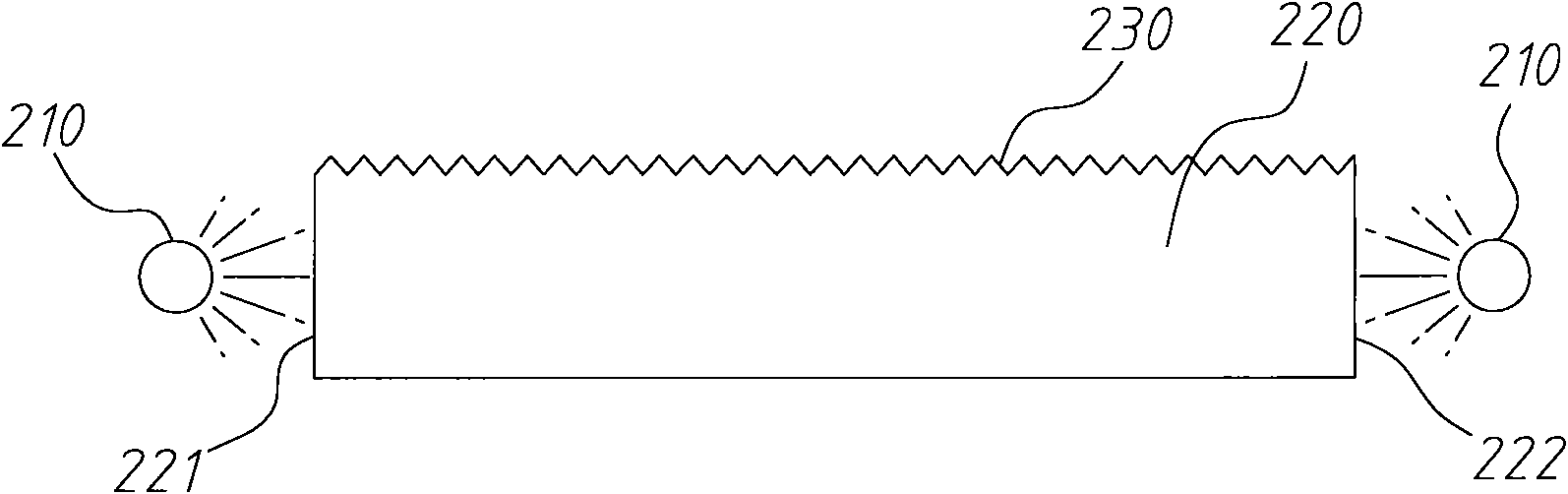

[0041] Figure 2B It is a schematic diagram of an embodiment of a light guide column for a flicker-free light source with a light diffusion patterned surface according to the present invention.

[0042] Figure 2B As shown, in addition to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com