A kind of thin integrated 3D three-dimensional display polarizer and preparation method thereof

A technology of stereoscopic display and polarizer, applied in the field of polarizer, can solve the problems of low optical transmittance, low production efficiency and high cost, and achieve the effects of high transmittance, high production efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

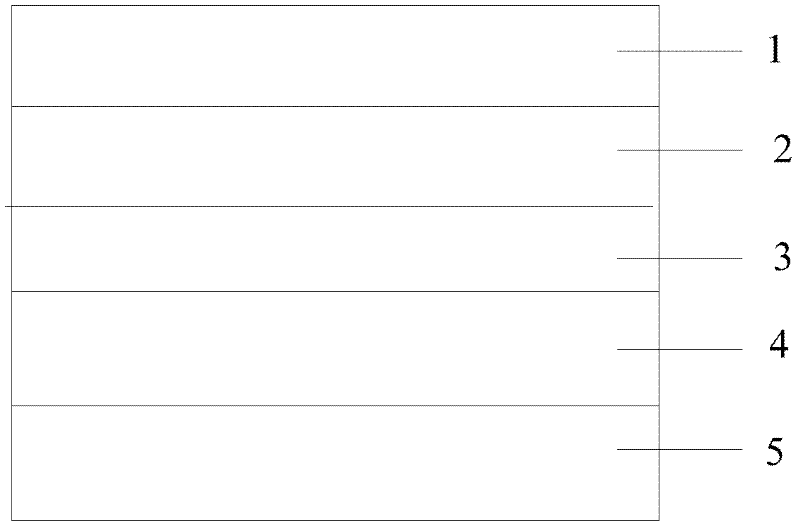

[0036] Raw materials: protective film, COP micro-retardation film with AG coating on the surface, PVA film, inner protective TAC film, peeling film

[0037] Adhesives: PVA glue, pressure sensitive adhesive.

[0038] Use PVA glue to compound the COP micro-retardation film and the inner protective TAC film on both sides of the dyed and stretched PVA film, and use pressure-sensitive adhesive to compound the peeling film on the other side of the inner protective TAC film. One side of the film is compounded with a protective film.

Embodiment 2

[0040] Raw materials: protective film, PC micro retardation film with AG coating on the surface, PVA film, inner protective TAC film, peeling film

[0041] Adhesive: PVA glue, pressure sensitive adhesive

[0042] Concrete operation is with embodiment 1.

Embodiment 3

[0044] Raw materials: protective film, TAC micro retardation film with AG coating on the surface, PVA film, inner protective TAC film, peeling film

[0045] Adhesive: PVA glue, pressure sensitive adhesive

[0046] Concrete operation is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com