Optical plate and backlight module adopting same

An optical plate and light source technology, applied in optics, optical components, nonlinear optics, etc., can solve problems such as light loss, reduce light utilization rate, increase light transmission interface loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

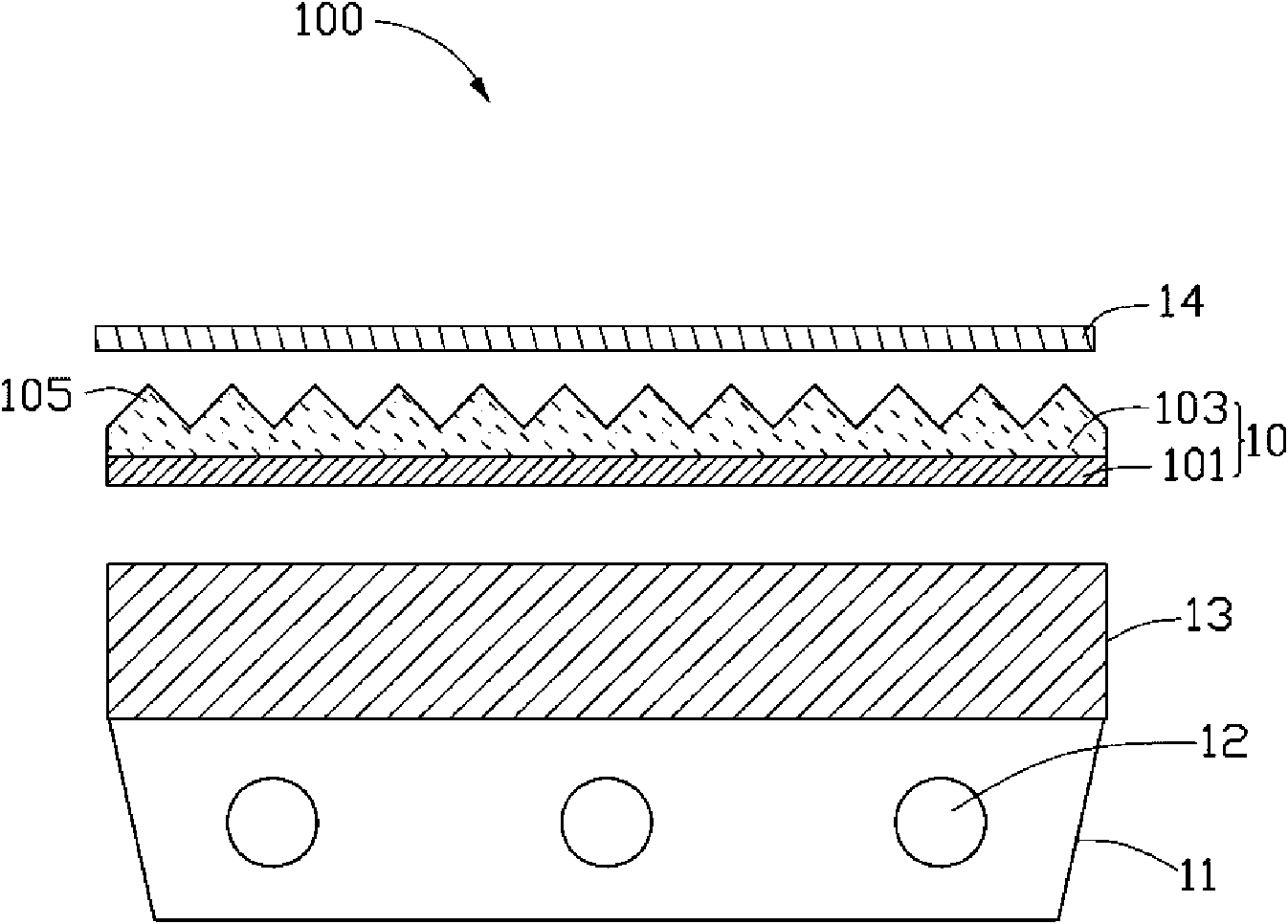

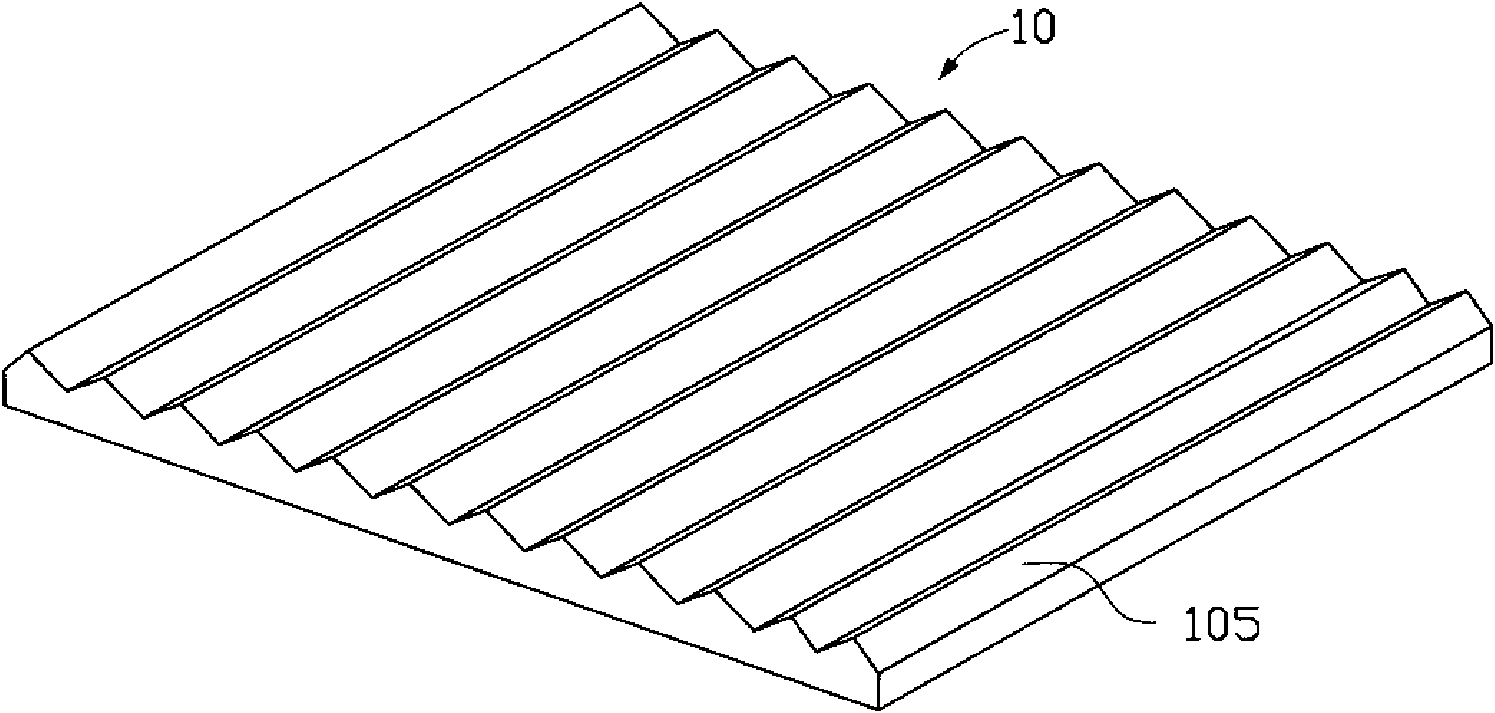

[0017] The optical plate of the present invention will be further described in detail below with reference to the drawings and embodiments.

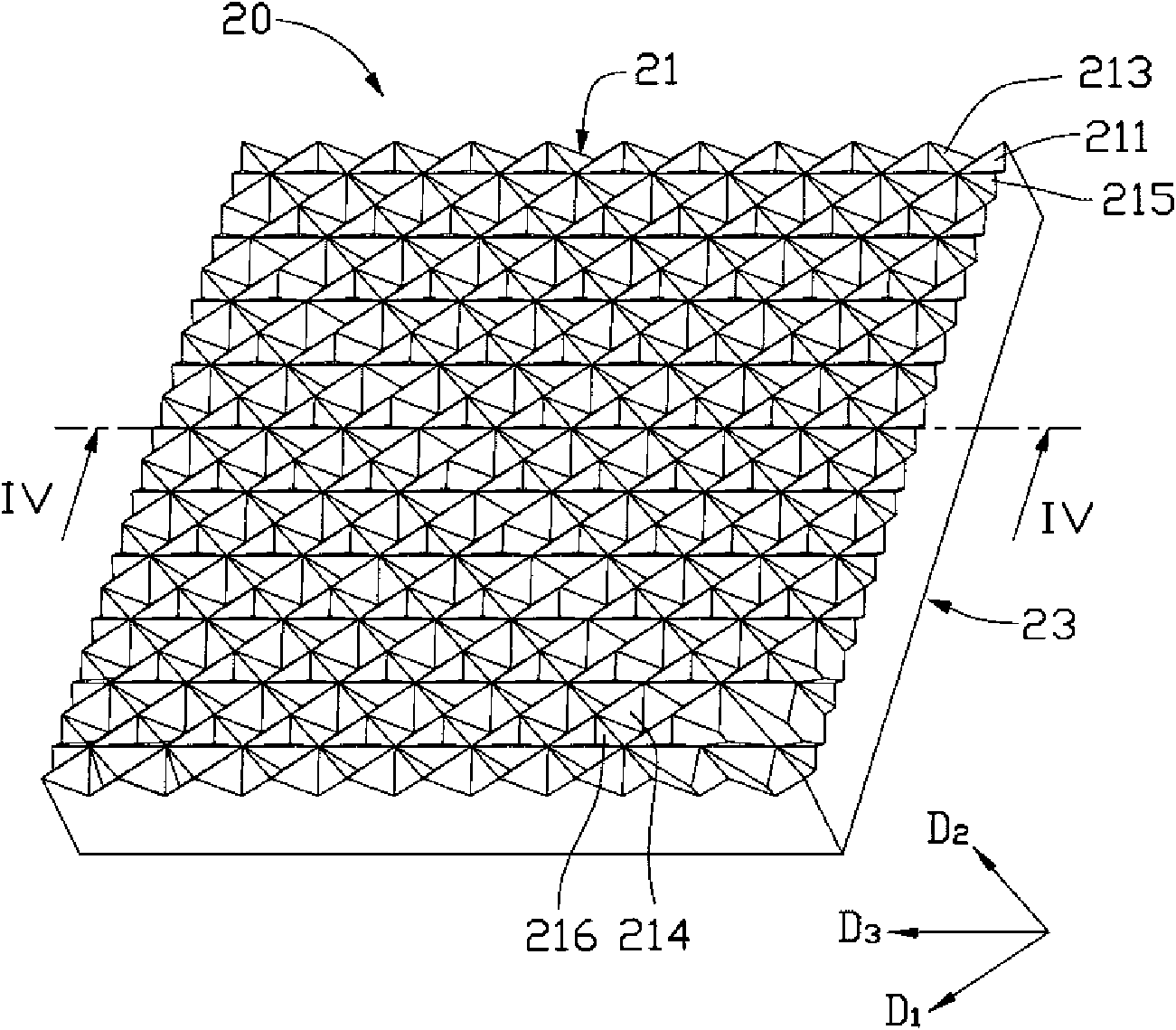

[0018] See image 3 and Figure 4 , shows the optical plate 20 of the preferred embodiment 1 of the present invention, which is composed of a transparent body, and the transparent body includes a light-emitting surface 21 and a bottom surface 23 opposite to the light-emitting surface 21 . The light emitting surface 21 has a plurality of 1 Extended first V-shaped protrusions 211, a plurality of extending along the second direction D 2 The extended second V-shaped protrusion 213 and a plurality of 3 The extended third V-shaped protrusion 215, the first V-shaped protrusion 211 intersects with the second V-shaped protrusion 213 to form a plurality of intersection points, and the third V-shaped protrusion 215 passes through some of the intersection points. The bottom surface 23 is a smooth surface, and it can be understood that the bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com