Magnetic ring automatic arrangement mechanism

An automatic arrangement and magnetic ring technology, applied in the direction of conveyor objects, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of product quality control, such as difficulty, time-consuming and labor-intensive, low labor efficiency, etc., to achieve effective product quality Simple structure of control and device, effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

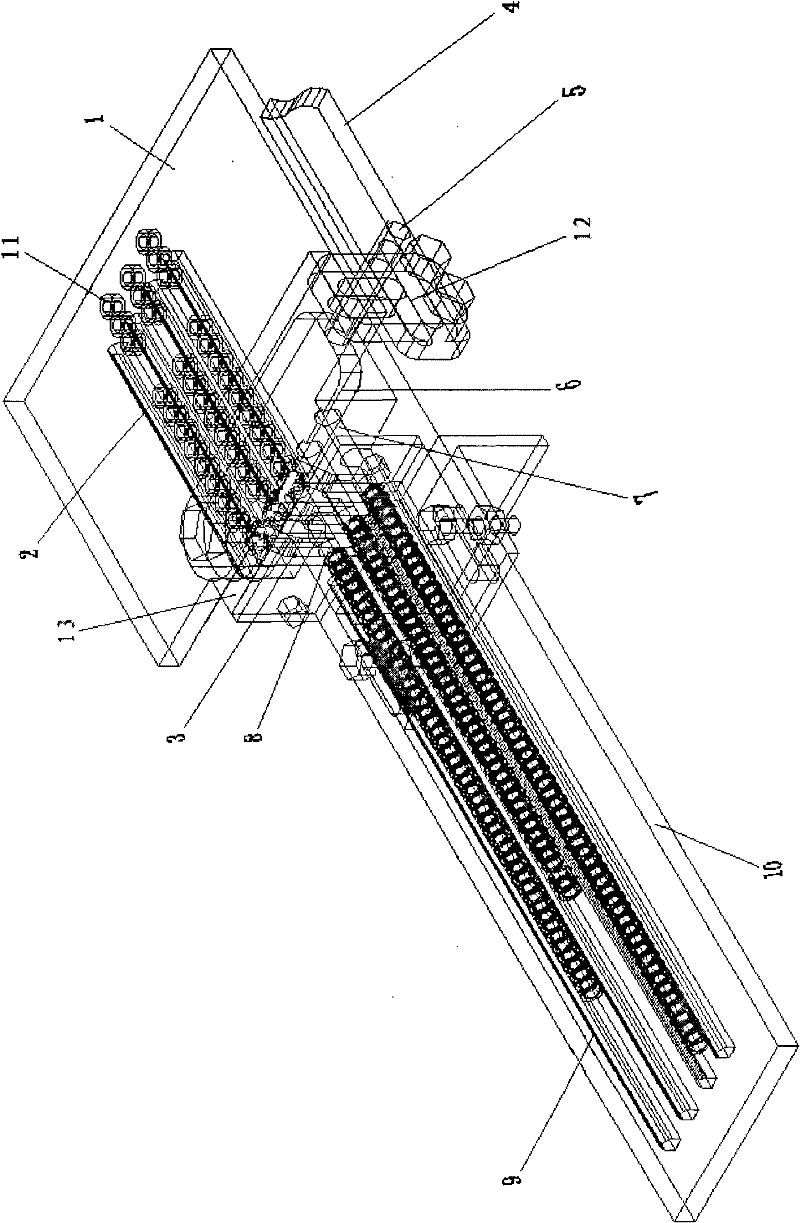

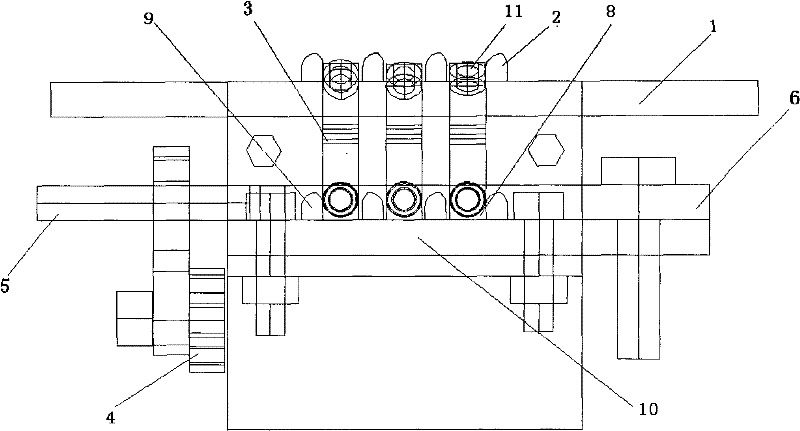

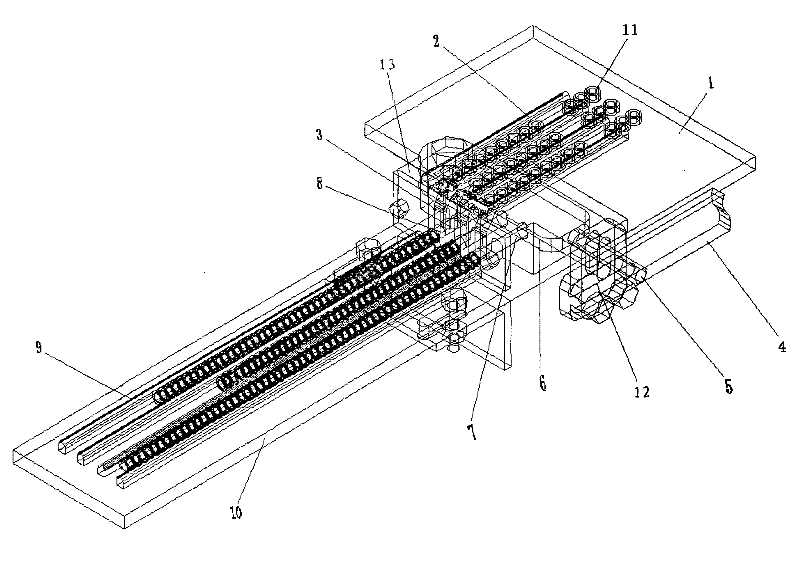

[0010] Embodiment 1: This embodiment has described the present invention:

[0011] Such as figure 1 , 2 As shown, this embodiment is composed of a green compact workbench 1, a magnetic ring arrangement platform 10, a push-out device 12, and an overturning plate 13. The compact compact workbench 1 and the magnetic ring arrangement platform 10 are arranged side by side, and the compact compact workbench 1 is positioned at a high On the magnetic ring arrangement platform 10, the flip plate 13 is arranged on the magnetic ring arrangement platform 10 between the green compact workbench 1, and these two parts are connected together, and the push-out device 12 is arranged under the compact workbench 1 and the magnetic ring arrangement platform 10 corresponds to the position.

[0012] Magnetic ring guide bars 2 are installed on the green compact workbench 1, and the space between the magnetic ring guide bars 2 matches the size and shape of the magnetic rings 11, so that the magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com