Transformer coil coiling mould capable of being finely adjusted

A technology for transformer coils and winding dies, which is applied in the field of transformer manufacturing, can solve the problems of low adjustment accuracy of winding dies diameter, increased production costs, and inability to adjust errors, and achieves the goal of streamlining the variety of tooling, reducing tooling, and improving product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

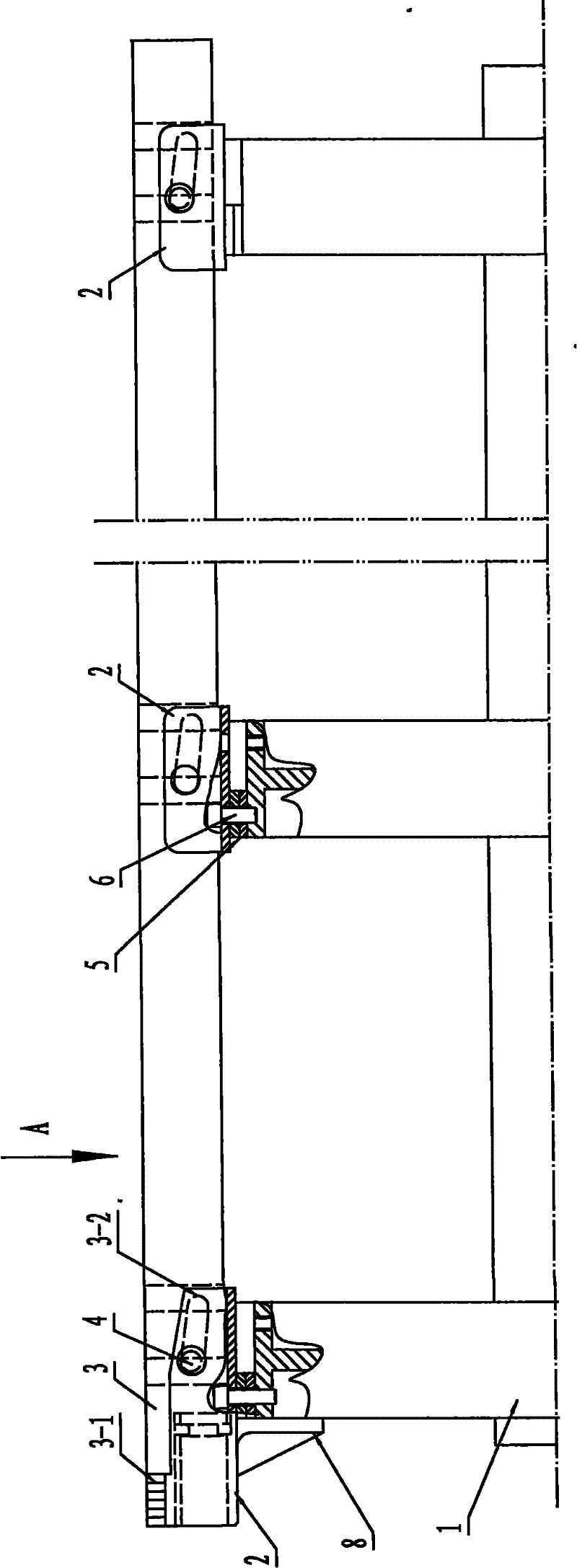

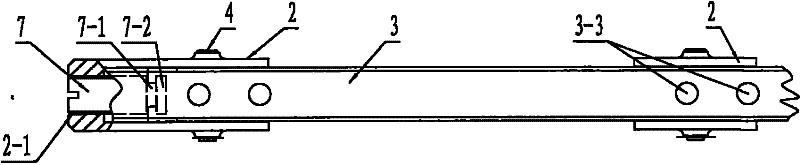

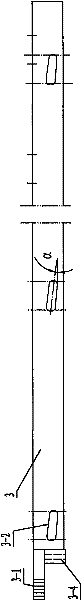

[0019] see Figure 1-3 , the present invention consists of a mold body 1, a spacer 5 and an adjustable stay assembly, the spacer is used for coarse adjustment of the diameter of the winding die, and the adjustable stay assembly is uniformly arranged around the outer periphery of the mold. In order to realize the free and accurate adjustment of the diameter of the winding die within a certain range, the key technology of the present invention is embodied in the design of the adjustable stay assembly. The adjustable stay assembly includes a stay body 3 , an adjustment screw 7 , a shaft base 2 and a rotating shaft 4 . The shaft base is used to support the rotating shaft, and it is evenly fixed on the mold body along the axial direction of the winding mold. Connect the hook block 8, and the hook block is fixed with the mold body. The oblique chute 3-2 is uniformly distributed on the stay body, and the rotating shaft 4 passes through the oblique chute and its two ends are support...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com