Intelligent control electromagnetic pulp boiling device for sleeper sulfur anchoring

An electromagnetic and sulfur technology, applied in the direction of cement mixing device, clay preparation device, raw material supply device for sale, etc., can solve the problems of difficult temperature control, high labor intensity, polluted gas, etc., and achieve simple processing and production, low input cost, and reduced The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

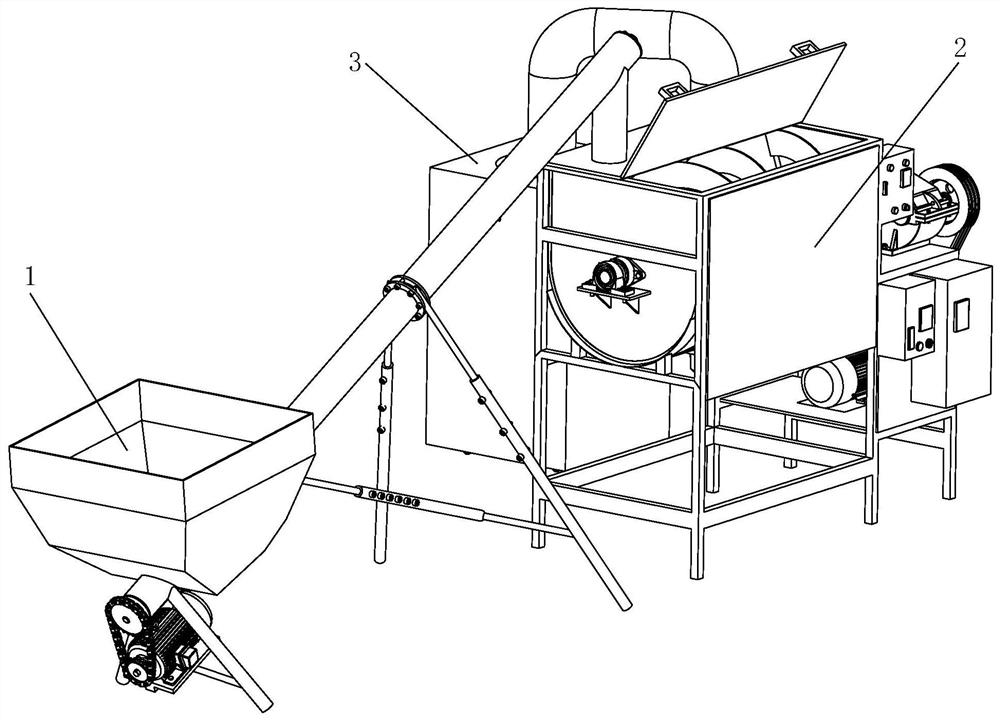

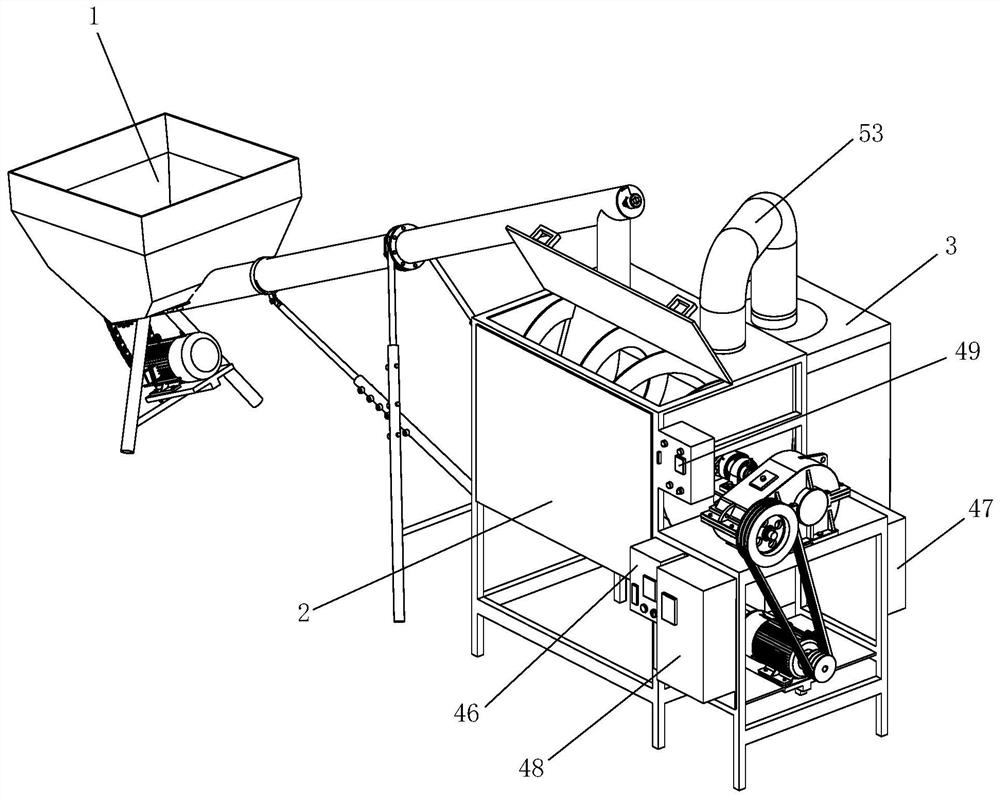

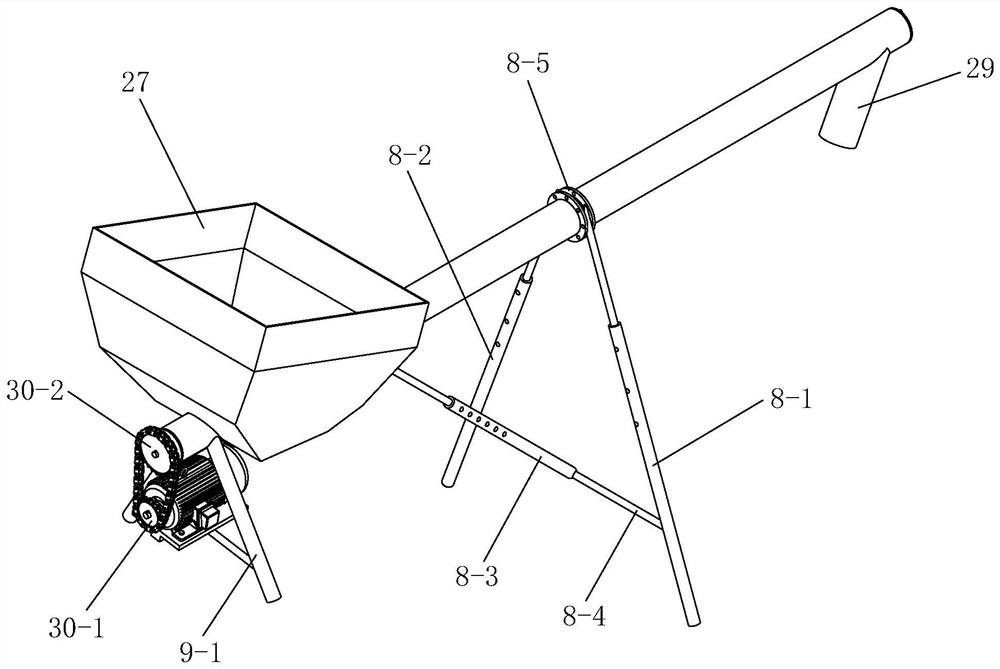

[0063] Such as figure 1 , figure 2 and Figure 6 As shown, the present invention includes an electromagnetic cooking pot 2, a material hoist 1 for conveying materials in the electromagnetic cooking pot 2, and a dust and SO 2 Gas tail gas purification device 3, the material hoist 1 is installed on the feed end side of the electromagnetic stewing pot 2, the material hoist 1 is arranged obliquely, and the tail gas purification device 3 is installed on the side of the electromagnetic stewing pot 2 On the outer wall, the bottom of the electromagnetic stewing pot 2 is provided with a discharge port 51; the electromagnetic stewing pot 2 includes a structural support 33, an installation platform 39, a pot body 32, a stirring mechanism, a stirring mechanism driving mechanism and a pair of pots. The electromagnetic heating system for heating the body 32, the installation platform 39 is fixed on the side of the structural support 33 away from the material hoist 1, the upper part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com