Method for automatically debugging audiphones

A debugging method and hearing aid technology, applied in the direction of electrical components, etc., can solve problems such as inconvenient purchase, incapable of mass production, and long cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] like figure 1 As shown, the equipment used in the present invention includes a hearing aid 1, a signal line 2, a signal processing converter 3 and corresponding hearing aid self-adjustment software (installed on a computer). The hearing aid 1 is connected to a signal processing converter 3 and software through a signal line 2 .

[0027] The invention relates to a hearing aid self-adjustment method, which comprises four steps of audible threshold test, comfort threshold test, automatic fitting and fine-tuning.

[0028] (1) The steps of the audible threshold test are as follows:

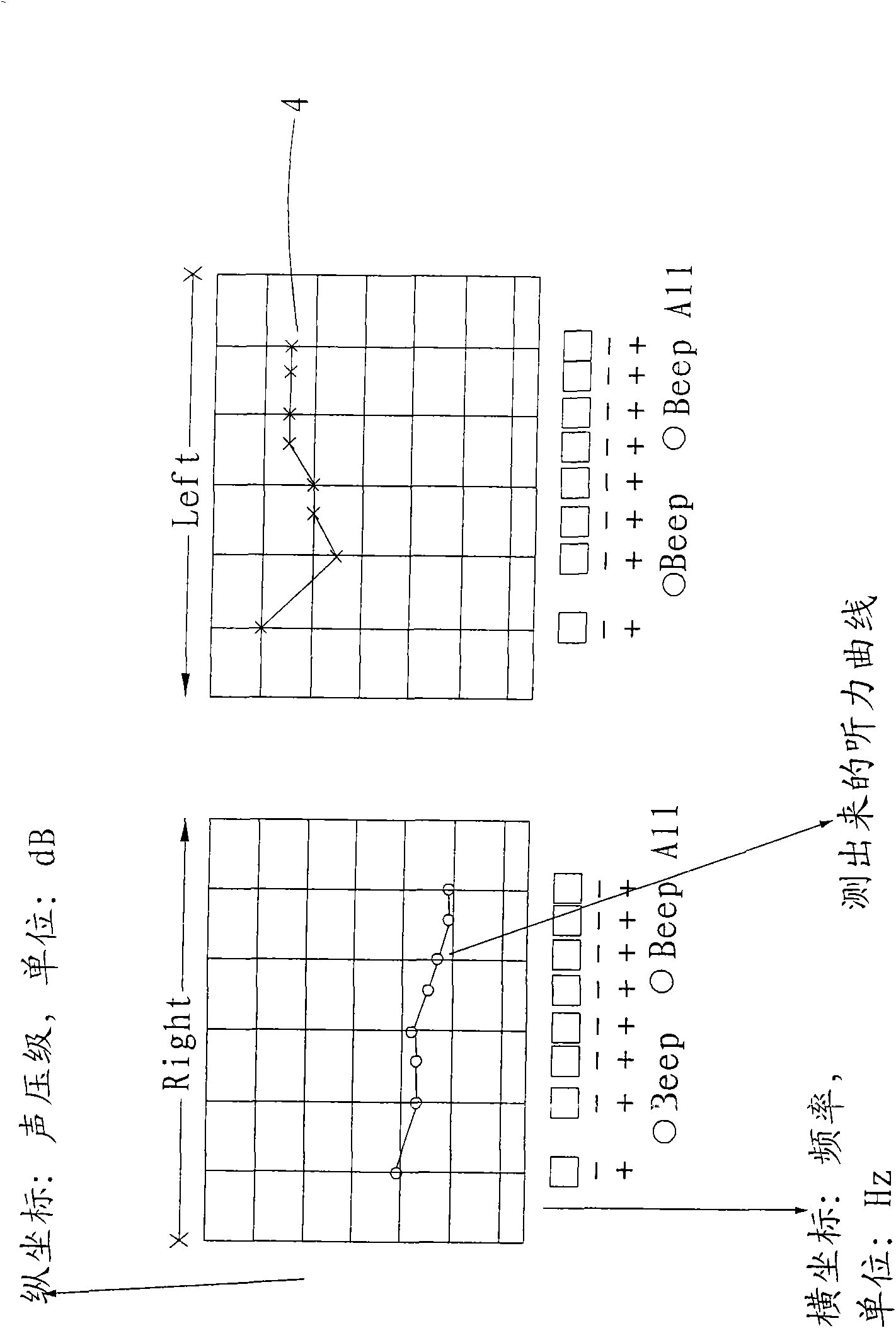

[0029] (1) On the software interface 4 (such as figure 2 shown) to select the starting frequency (eg figure 2 shown on the abscissa), and the starting volume (eg figure 2 The vertical axis shown: sound pressure level);

[0030] (2) Click the sound button on the software, and the hearing aid will emit pure tone at the initial frequency and volume, or narrow-band noise, so as to achieve th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com