High-temperature and high-pressure positive action desuperheater

A high-temperature, high-pressure, positive-acting technology, applied in superheating temperature control, steam superheating, steam generation, etc., can solve the problems of metal piston ring wear, vibration, and high cost of replacing spare parts, so as to improve the up and down orientation, improve the service life, The effect of low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

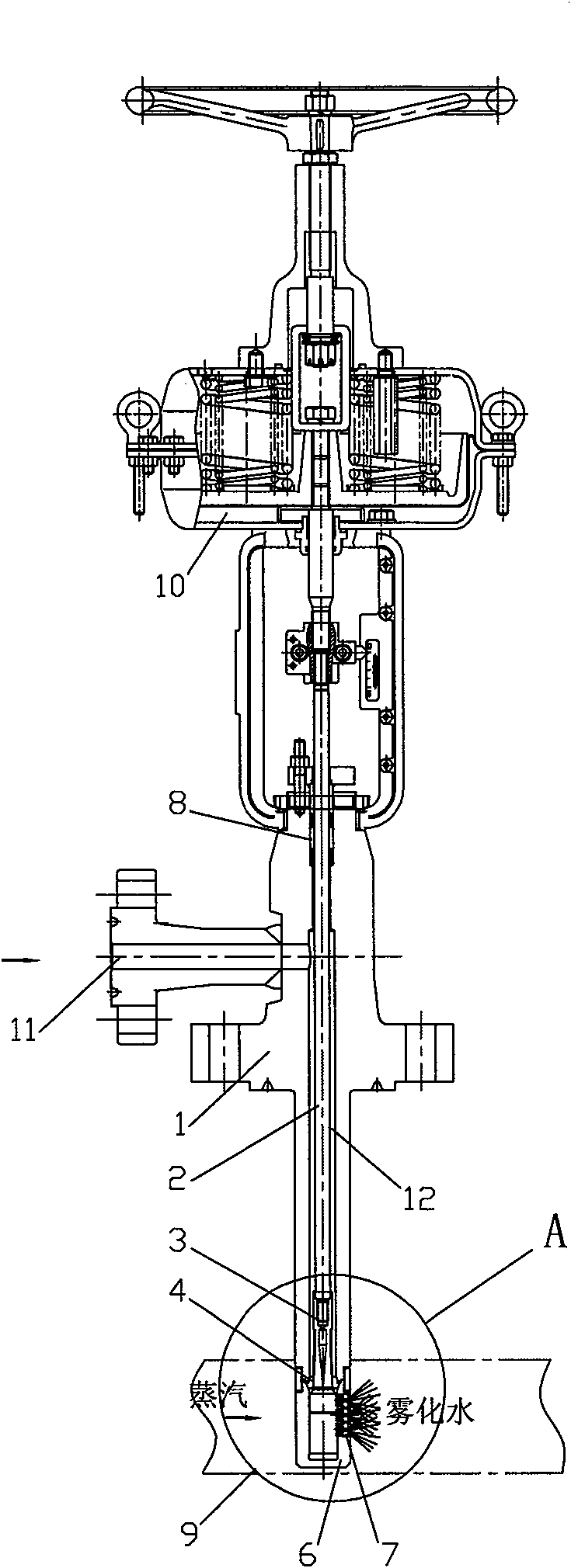

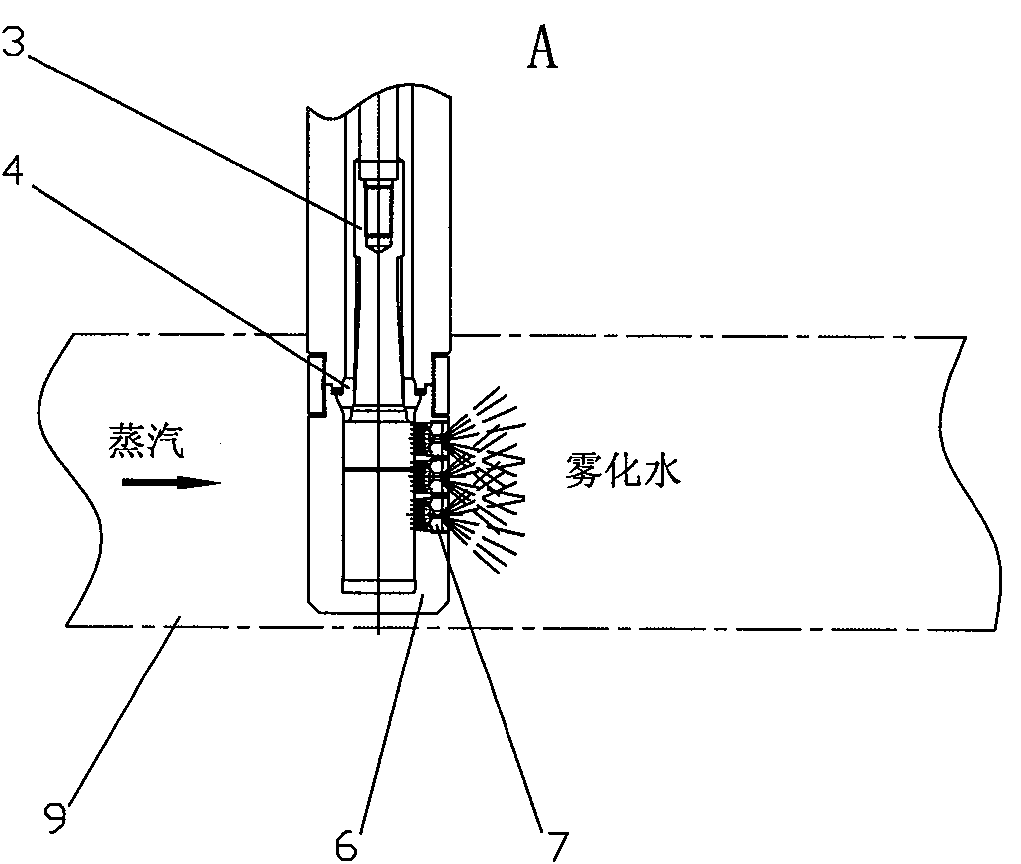

[0013] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

[0014] like Figure 1 to Figure 4 As shown, the present invention includes a valve body 1, a desuperheating water inlet 11 provided on the valve body 1 is communicated with a valve cavity 12 in the valve body 1, a valve stem 2 is arranged in the valve cavity 12, and the lower end of the valve stem 2 is fixed with a A nozzle sleeve 6 is fixed on the lower end of the valve core 3 and the valve body 1 , and a vortex atomizing nozzle 7 is arranged on the side wall of the nozzle sleeve 6 .

[0015] A valve seat 4 is arranged between the valve body 1 and the nozzle sleeve 6, and the valve core 3 cooperates with the valve seat 4 to adjust the flow rate of the desuperheating water, which can be tightly closed. Because the valve core 3 and valve seat 4 are in the form of single-seat sealing, the leakage level of the desuperheater can be increased from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com