Paraffin wax emulsion as well as preparation method and application thereof

A paraffin emulsion and hydrophilic technology, applied in the preparation of particleboard, paraffin emulsion and its preparation, artificial board waterproofing agent and its preparation field, can solve the problem of solid particle size and uneven distribution, waste of paraffin, influence on adhesive curing and other problems, to achieve good mechanical stability, reduce production costs, and improve waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Prepare materials according to the following weight ratio: polyoxyethylene ether 6kg, glyceride 12kg, paraffin oil 12kg, water 70kg;

[0046] Completely add wax, oily ester and polyoxyethylene ether into the reaction axe, heat to make it melt completely; raise the temperature to 90°C, after the materials are completely melted, control the stirring speed to 2800 rpm; quickly add the first batch of water 15kg, water The temperature is 90-95°C, keep stirring at the same speed for 5 minutes; at the temperature of 90°C, adjust the speed to 1000 rpm, and add the second batch of water 55kg evenly within 2 minutes, the temperature of the water is 70-75°C, Keep stirring at the same speed for 5 minutes; adjust the speed to 100 rpm, pass cooling water, stir within 1 hour to cool the emulsion to below 50°C and then discharge.

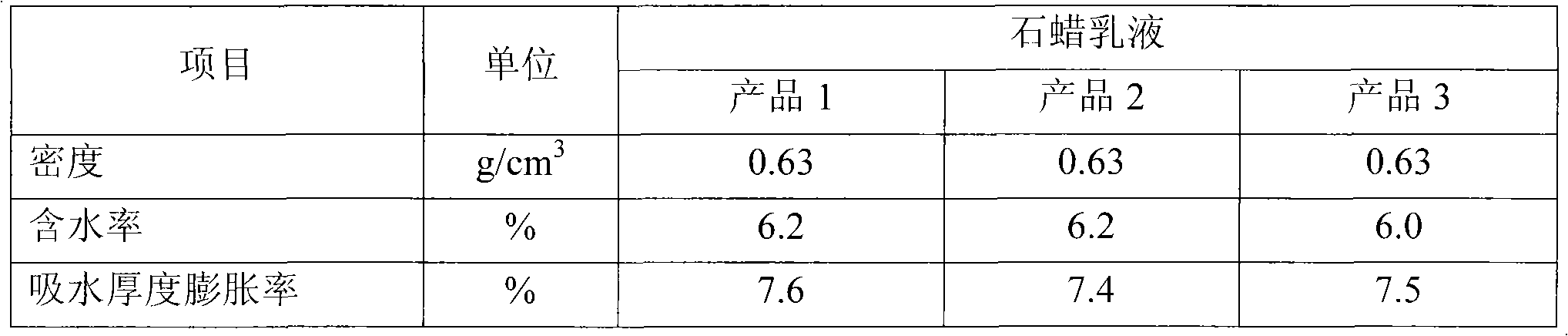

[0047] The technical index of the paraffin emulsion product produced by the present embodiment is as follows:

[0048] Appearance: milky white milky liquid ...

Embodiment 2

[0053] Prepare materials according to the following weight ratio: polyoxyethylene ether 8kg, glyceride 16kg, beeswax 16kg, water 60kg;

[0054] Completely add wax, oily ester and polyoxyethylene ether into the reaction axe, heat to make it melt completely; raise the temperature to 90°C, after the materials are completely melted, control the stirring speed to 2800 rpm; quickly add the first batch of water 20kg, water The temperature is 90-95°C, keep stirring at the same speed for 5 minutes; at the temperature of 90°C, adjust the speed to 1000 rpm, add the second batch of water 40kg evenly within 2 minutes, the temperature of the water is 70-75°C, Keep stirring at the same speed for 5 minutes; adjust the speed to 100 rpm, pass cooling water, stir within 1 hour to cool the emulsion to below 50°C and then discharge.

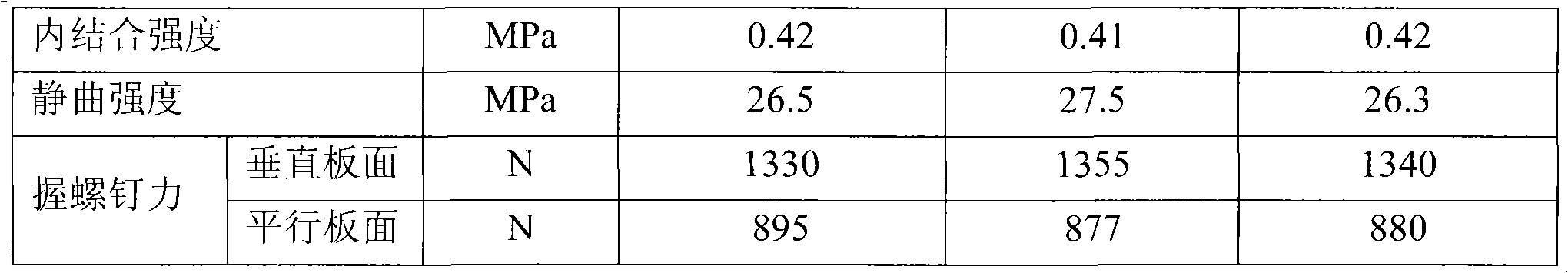

[0055] The technical index of the paraffin emulsion product produced by the present embodiment is as follows:

[0056] Appearance: milky white milky liquid

[0057...

Embodiment 3

[0061] Prepare materials according to the following weight ratio: polyoxyethylene ether 9kg, glyceride 18kg, vegetable wax 18kg, water 55kg;

[0062] Completely add wax, oily ester and polyoxyethylene ether into the reaction axe, heat to make it melt completely; raise the temperature to 90°C, after the materials are completely melted, control the stirring speed to 2900 rpm; quickly add the first batch of water 25kg, water The temperature is 90-95°C, keep stirring at the same speed for 5 minutes; at the temperature of 90°C, adjust the speed to 1000 rpm, add the second batch of water 30kg evenly within 2 minutes, the temperature of the water is 70-75°C, Keep stirring at the same speed for 7 minutes; adjust the speed to 100 rpm, pass cooling water, stir within 1 hour to cool the emulsion to below 50°C and then discharge.

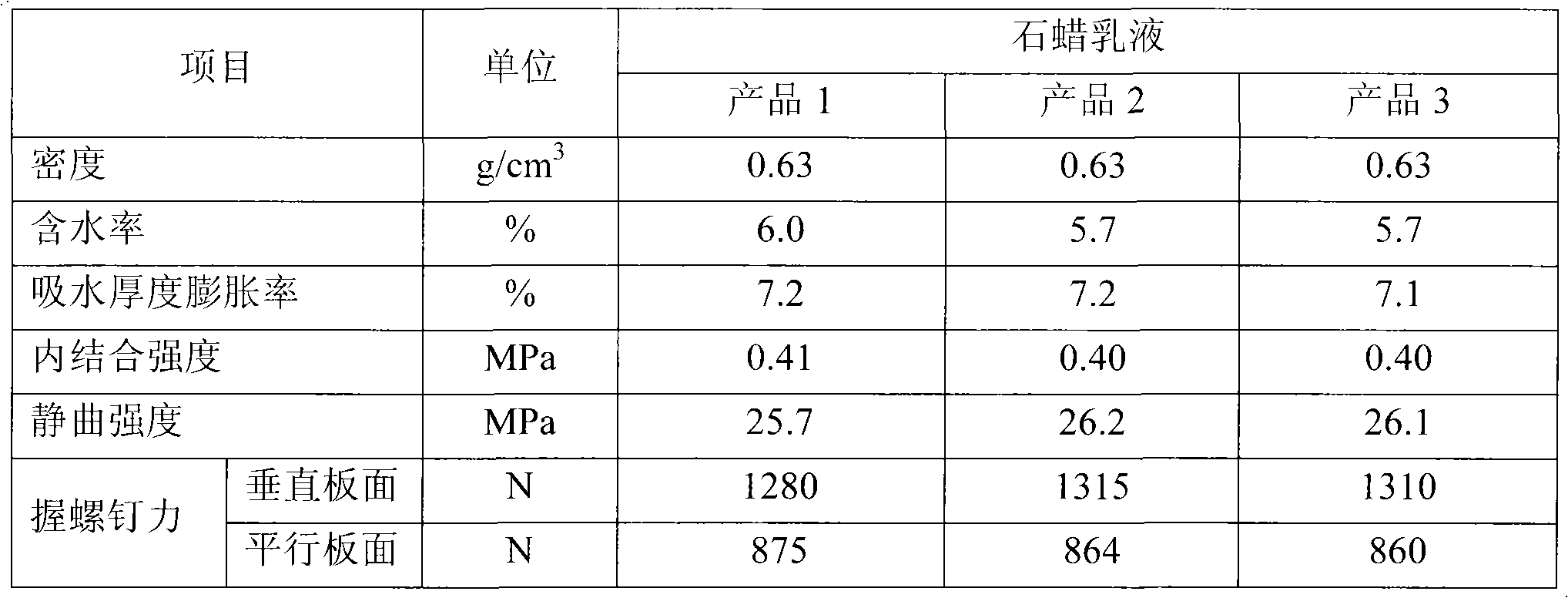

[0063] The technical index of the paraffin emulsion product produced by the present embodiment is as follows:

[0064] Appearance: milky white milky liquid

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap