Buckling structure

A buckle structure and buckle parts technology, which is applied in the direction of cabinet/cabinet/drawer components, mechanical equipment, fixing devices, etc., can solve problems such as inconvenient operation, easy falling of screws, and broken hooks, etc., to achieve Improve convenience and solve the effect of difficult disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention are described below through specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

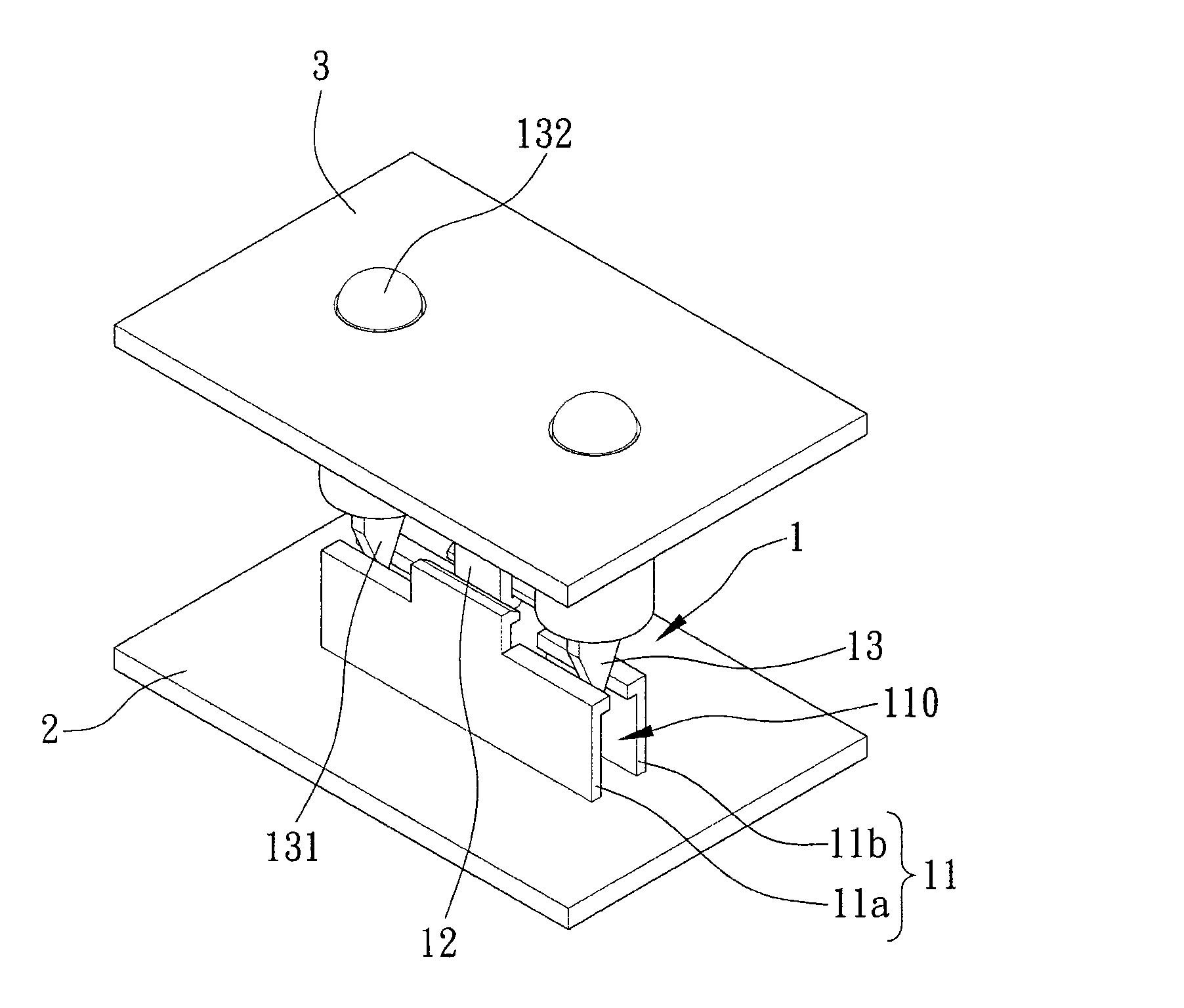

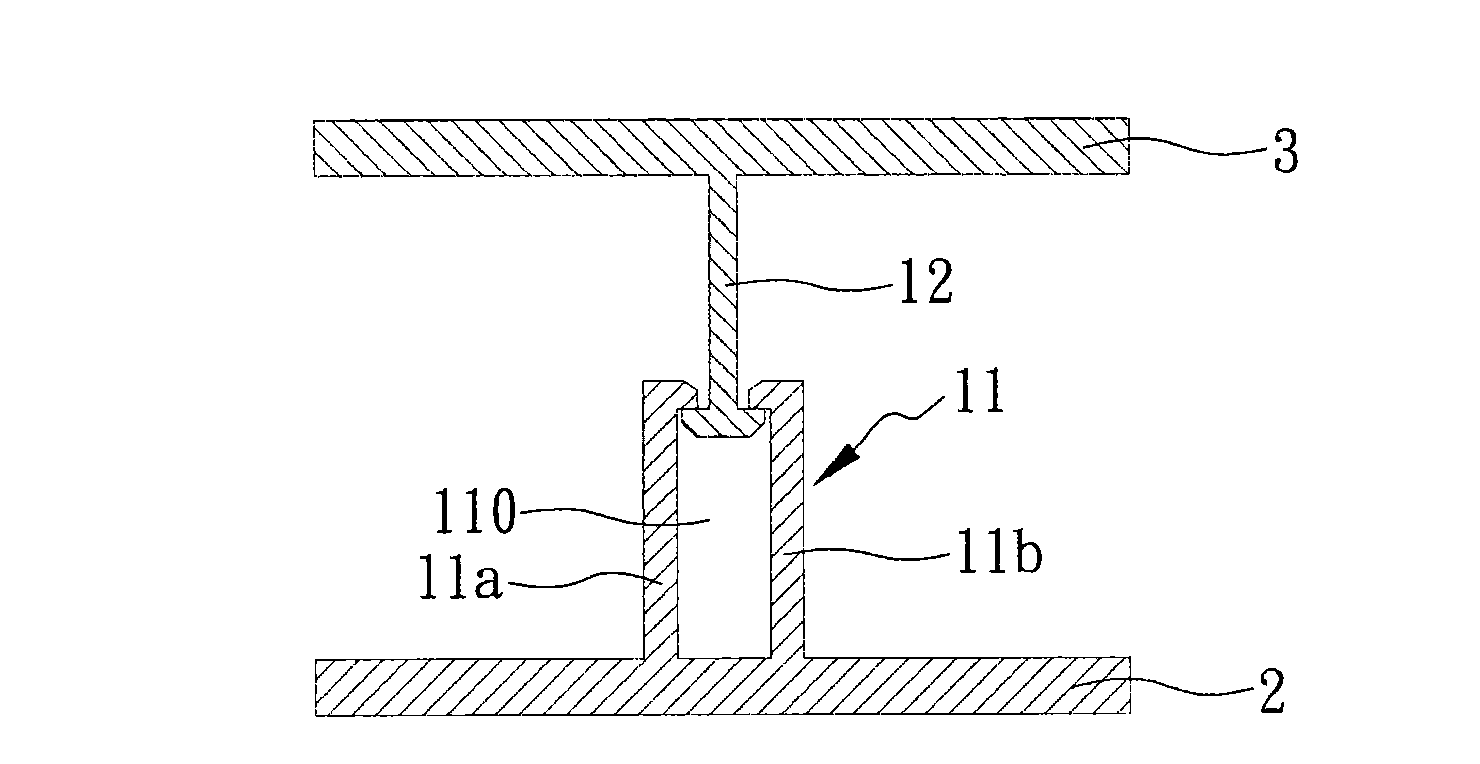

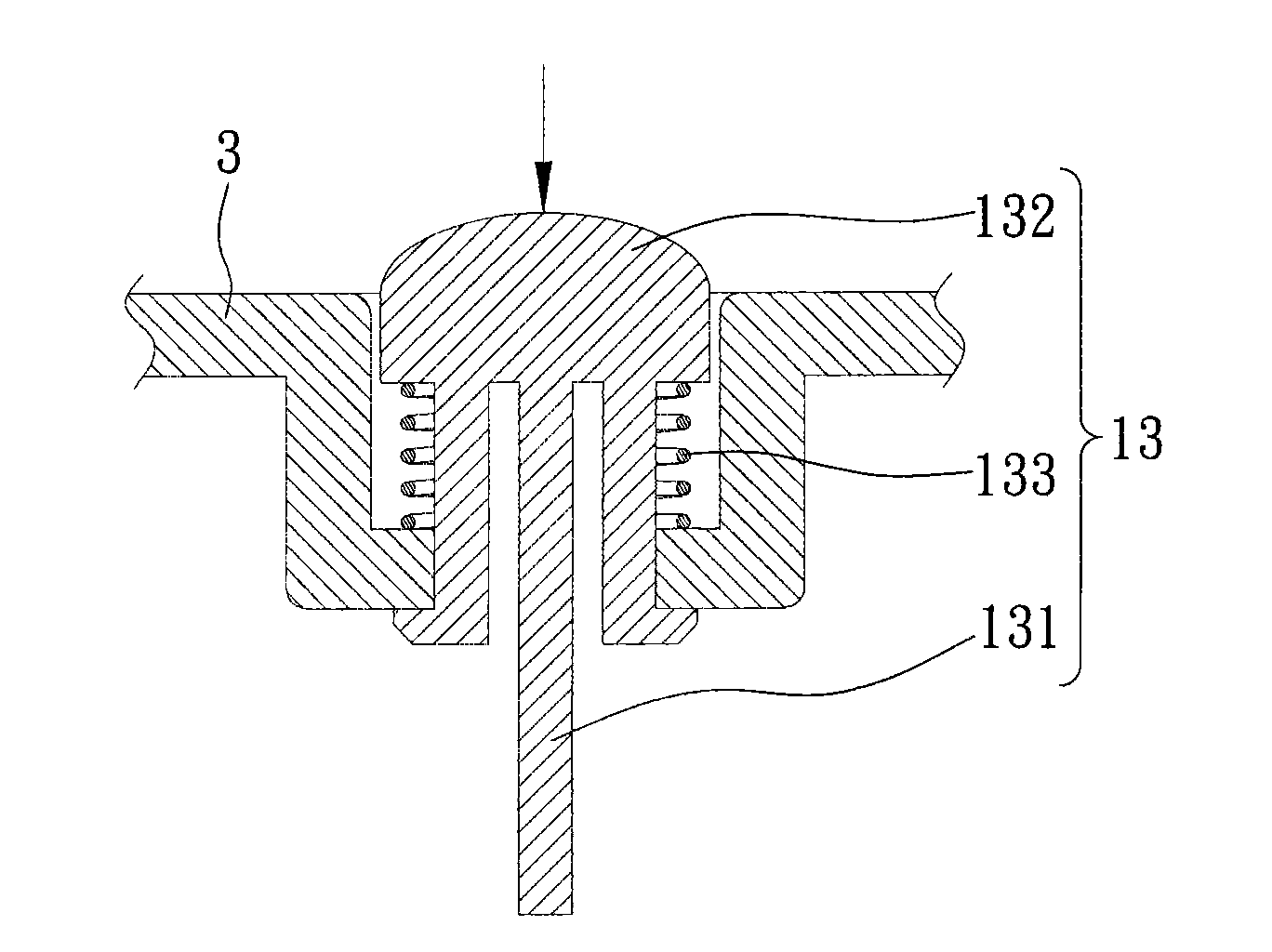

[0031] see figure 1 , is a three-dimensional combined schematic view of the buckle structure 1 and the first and second shells 2 and 3 applied to the buckle structure 1 of the present invention; as shown in the figure, the present invention provides a method for fixing the first shell 2 and the buckle structure 1 of the second housing 3 , the buckle structure 1 includes a first buckle 11 , a second buckle 12 and an unlocking piece 13 .

[0032] The first buckle 11 is disposed on the first housing 2. In this embodiment, the first buckle 11 is two first hooks arranged on the first housing 2 at intervals corresponding to each other. 11a and 11b, the first hooks 11a and 11b are L-shaped and arranged in opposite directions (ie hook to ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com