Water-tight connector and relay connector

A connector and waterproof technology, which is applied in the field of connectors and relay connectors, can solve the problems of difficult clamping control, changes in the tightness of elastic sleeve members and cables, and it is difficult for cables to adhere evenly. The effect of simple connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

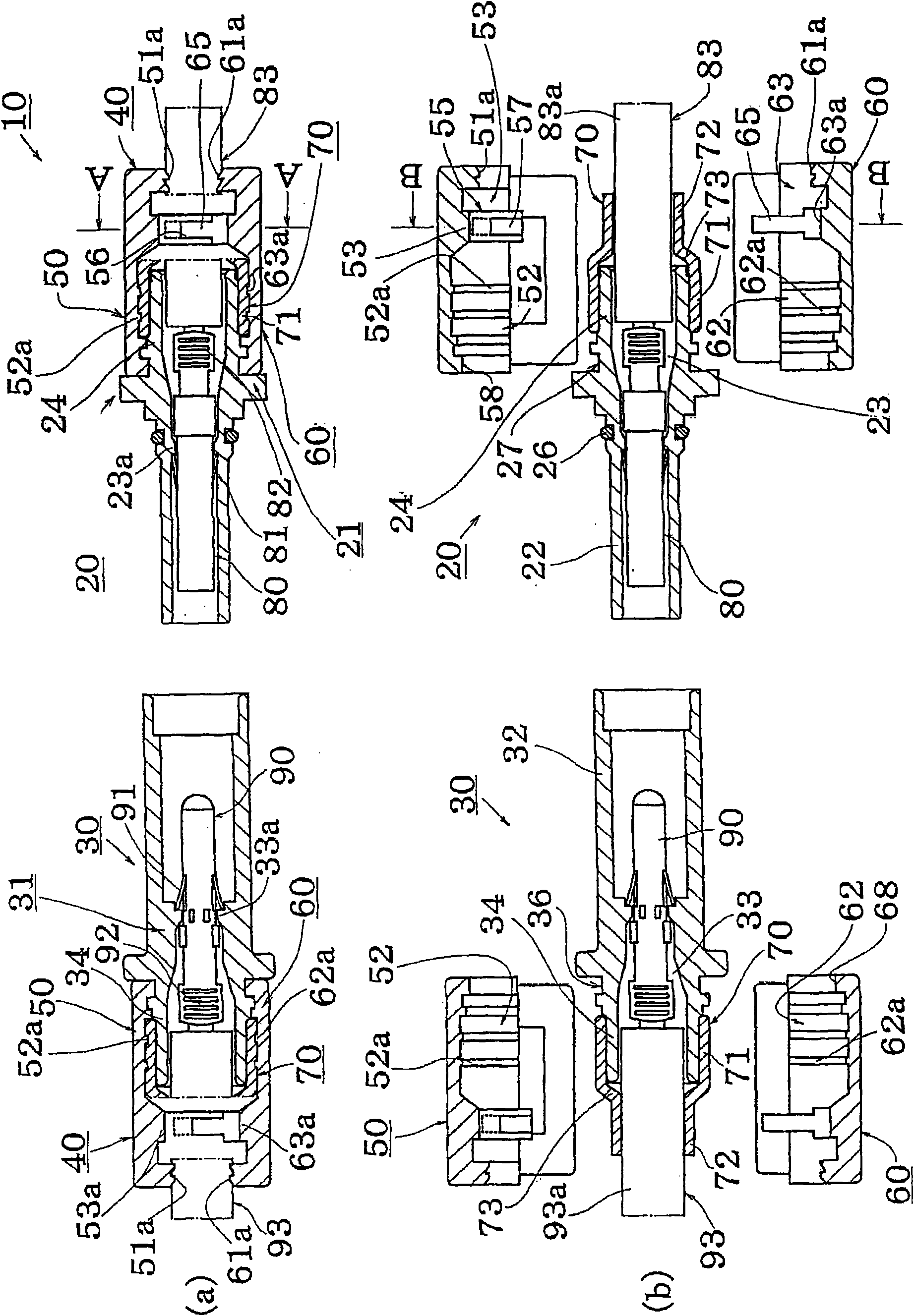

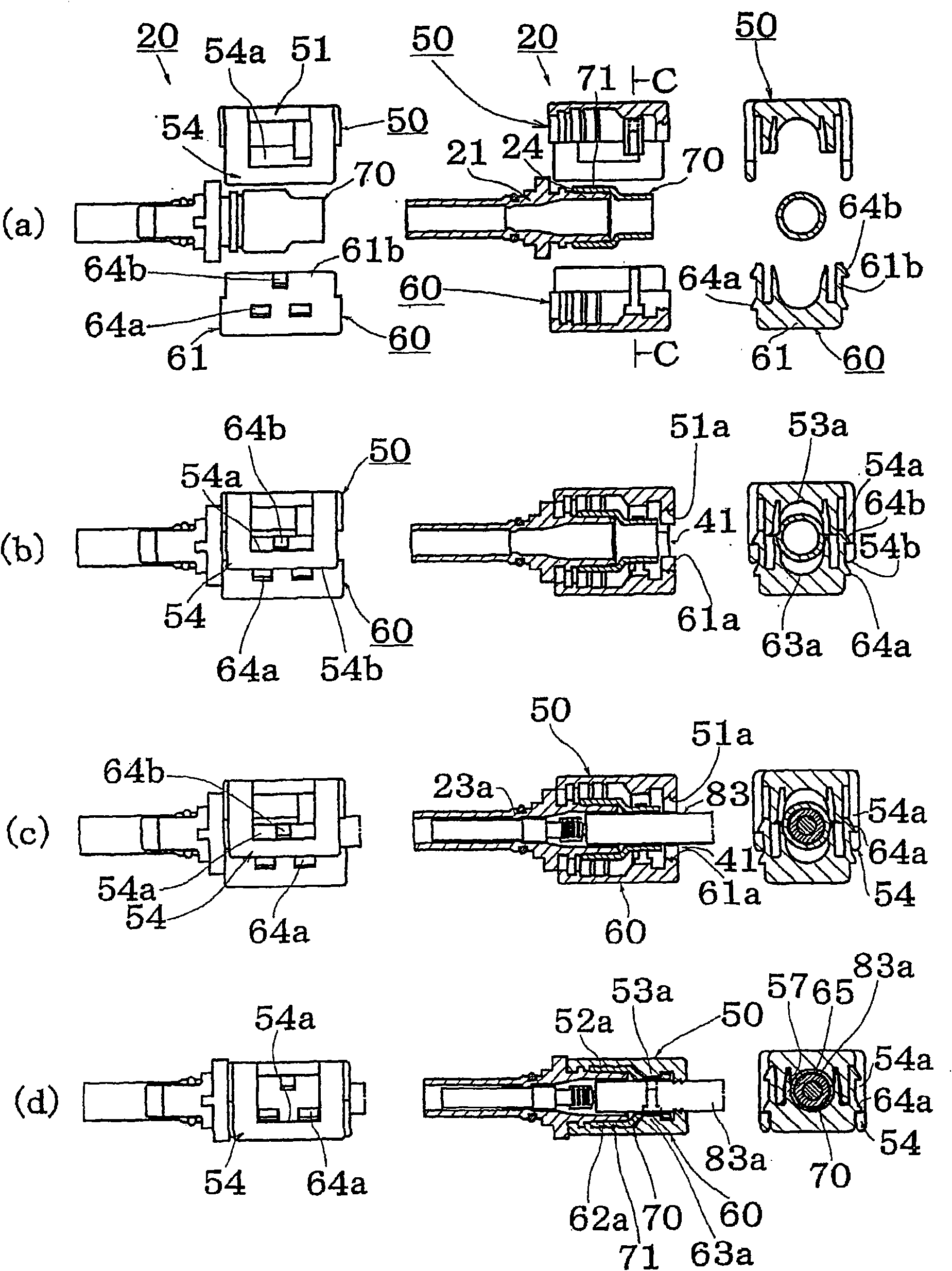

[0066] An example in which the waterproof connector of the present invention is used for the relay connector 10 will be described below with reference to the drawings.

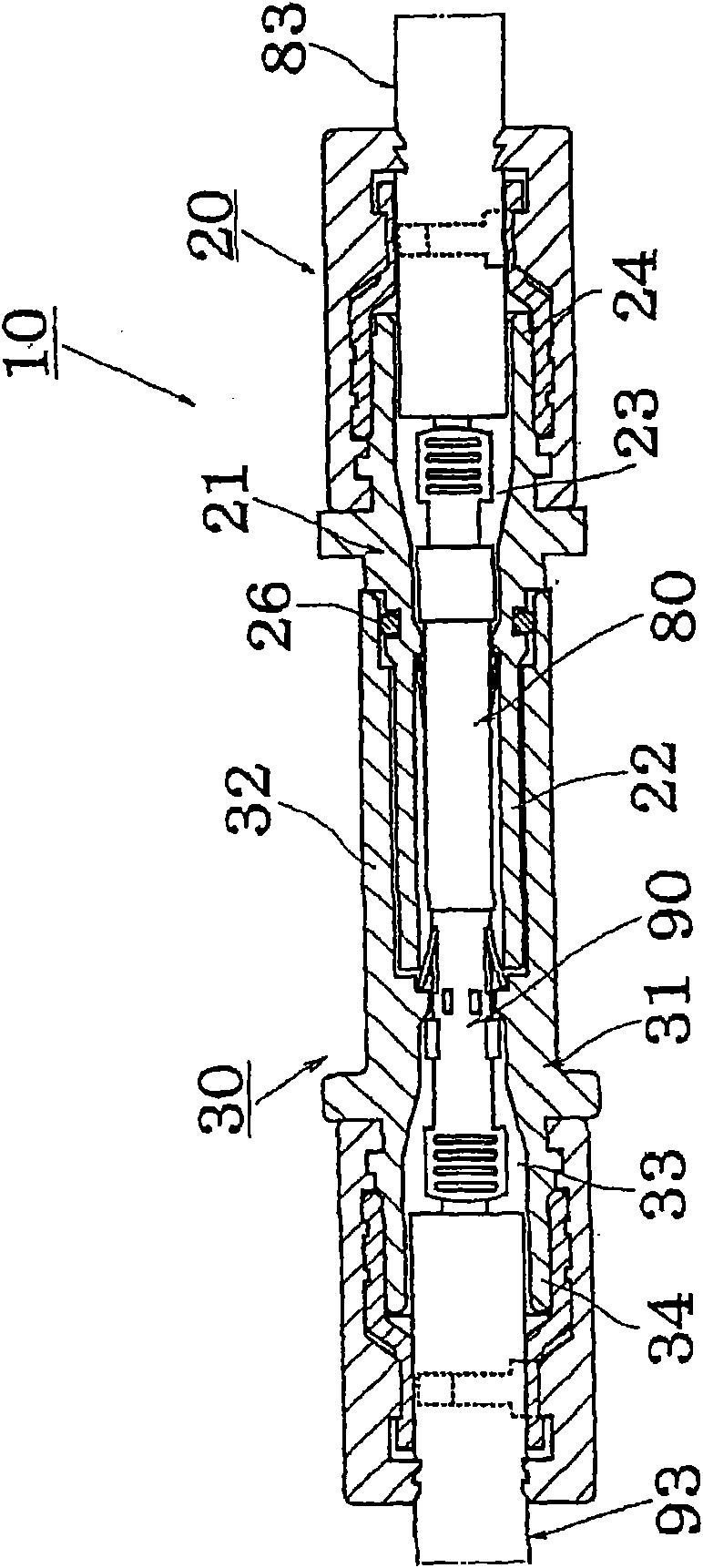

[0067] figure 1 (a) is a longitudinal section of a state before receptacle connector 20 and plug connector 30 are fitted, figure 2 It is the longitudinal section of the state after fitting.

[0068] The relay connector 10 includes a receptacle connector 20 and a plug connector 30 , each having housings 21 and 31 , a waterproof tube 70 , and a clamp housing 40 .

[0069] figure 1 (b) shows a state where the clamp housing 40 is removed.

[0070] figure 1 (a) The cable 83 and the waterproof tube 70 on the front side are cut away in order to show the fitting portion of the female housing 50 and the male housing 60 in the drawing direction inside.

[0071] Such as figure 2 As shown, in the relay connector 10 , the receptacle connector 20 and the plug connector 30 are fitted together, so that the terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com