Manufacturing method of shell

A manufacturing method and casing technology, applied to the photoplate-making process of the pattern surface, photosensitive materials used in optical mechanical equipment, electrical equipment shells/cabinets/drawers, etc., can solve the problem of product yield reduction and thermal deformation of fiber materials , It is difficult to realize the weaving pattern and other problems, and achieve the effect of good appearance and simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The manufacturing method of the shell of the present invention is used to obtain the weaving pattern effect on the surface of the shell. The manufacturing method of the shell comprises the following steps:

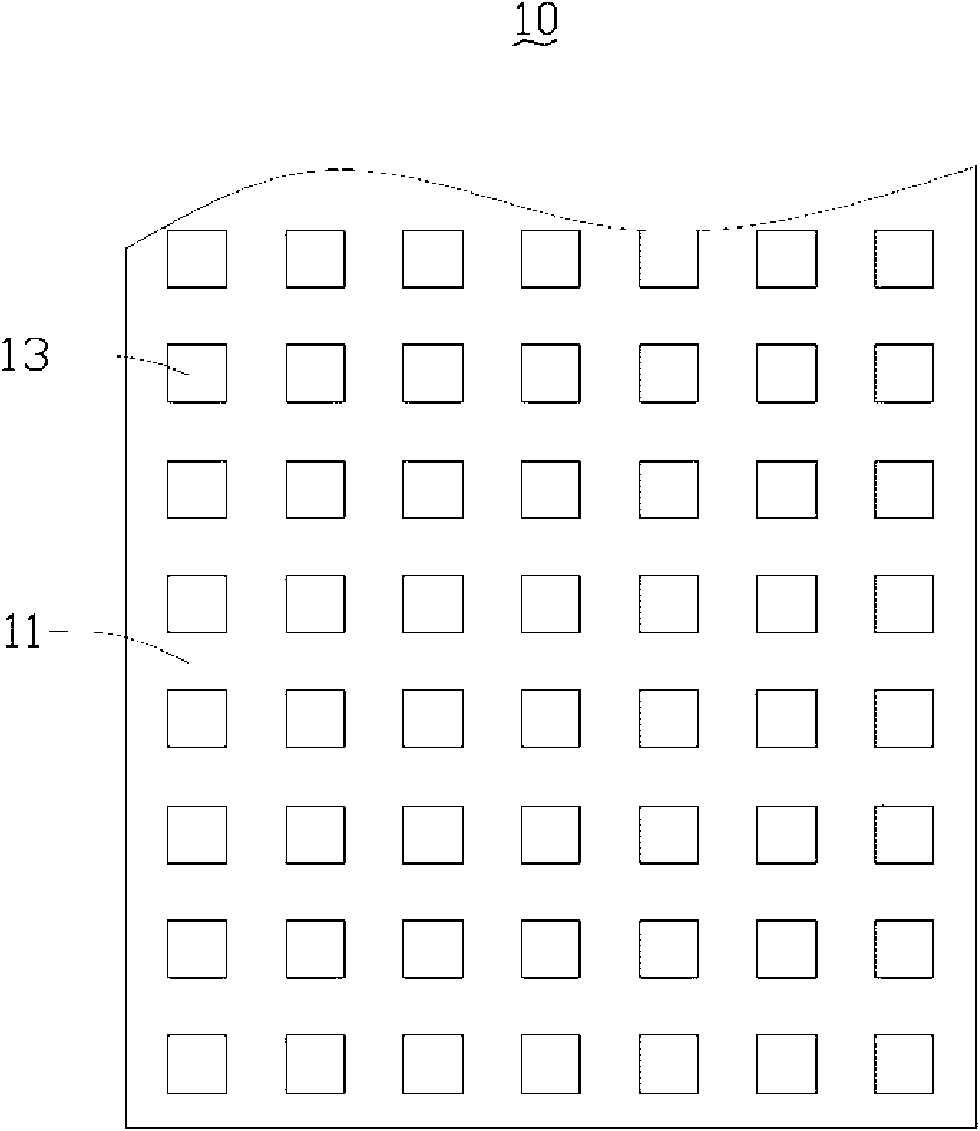

[0019] see figure 1 As shown, a film 10 is designed and manufactured, and a light-shielding area 11 and a plurality of light-transmitting areas 13 are formed on the film 10 . The light-shielding area 11 is coated with a photosensitive material, such as opaque photosensitive glue. The light-transmitting regions 13 are arranged in a matrix, which are transparent films and not coated with photosensitive materials.

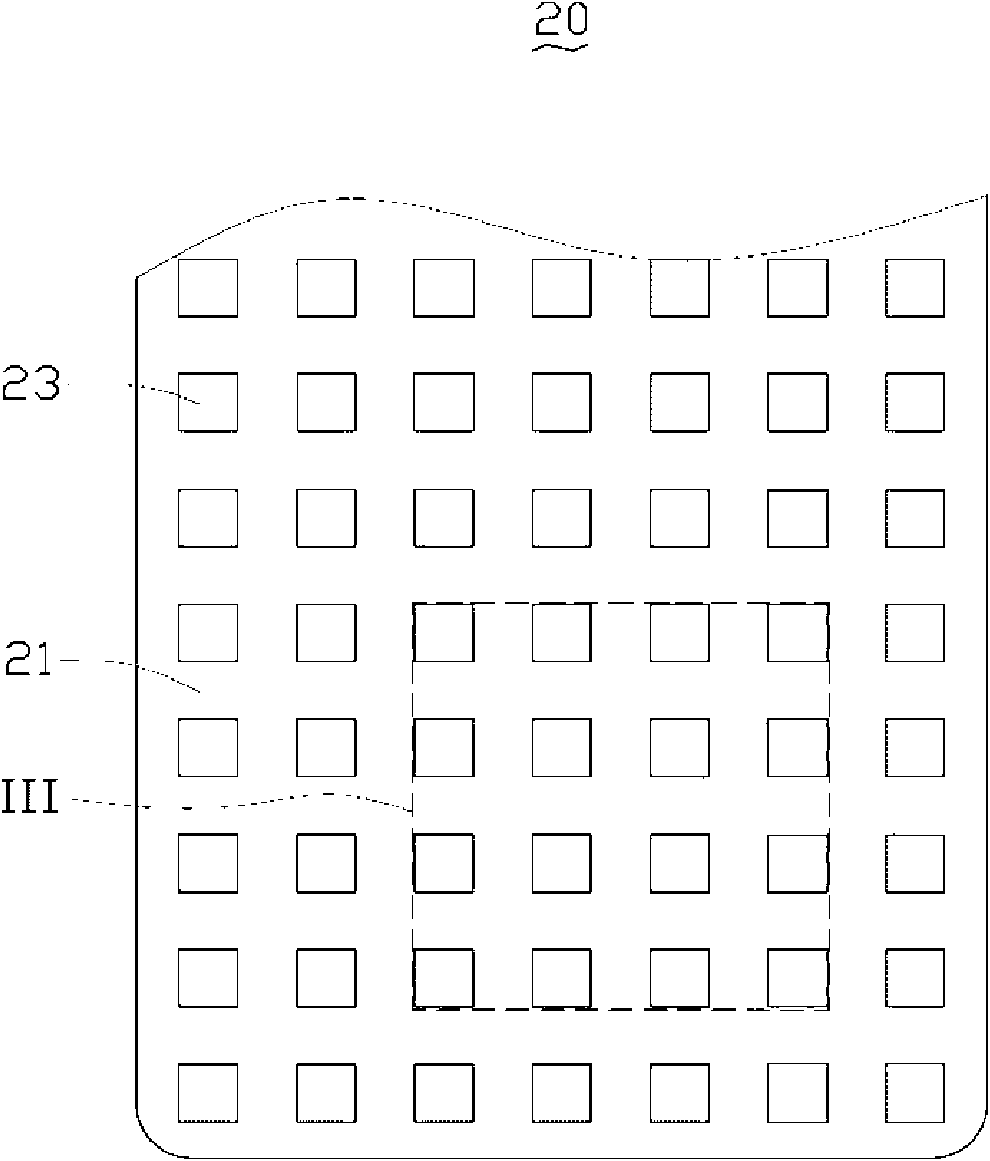

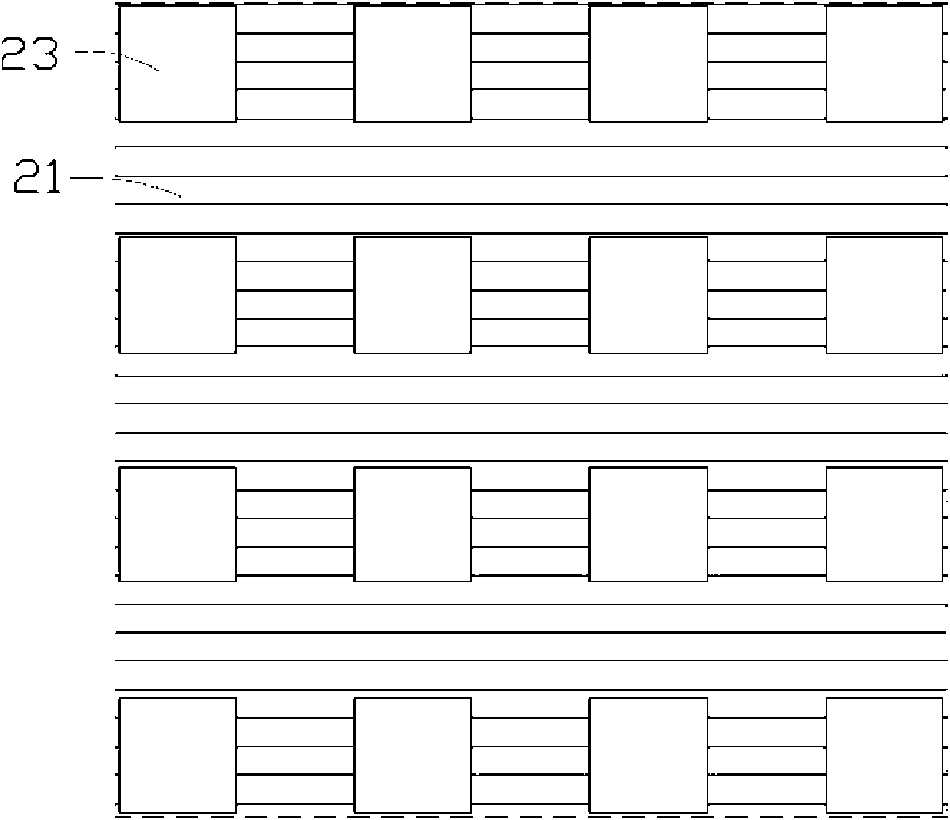

[0020] see figure 2 As shown, a housing 20 is provided. The shell 20 can be a metal shell, such as aluminum, aluminum alloy, titanium, titanium alloy or stainless steel, or can be a plastic shell. The appearance surface of the casing 20 includes several shielding areas 23 and the first brushed area 21 surrounding the several shielding areas 23 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com