Helicopter with separated tip jet device and main rotor wing

A jet wing and main rotor technology, which is applied in the field of jet wing tip helicopters, can solve the problems of high efficiency, reduced main rotor speed, and reduced main rotor tip propulsion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

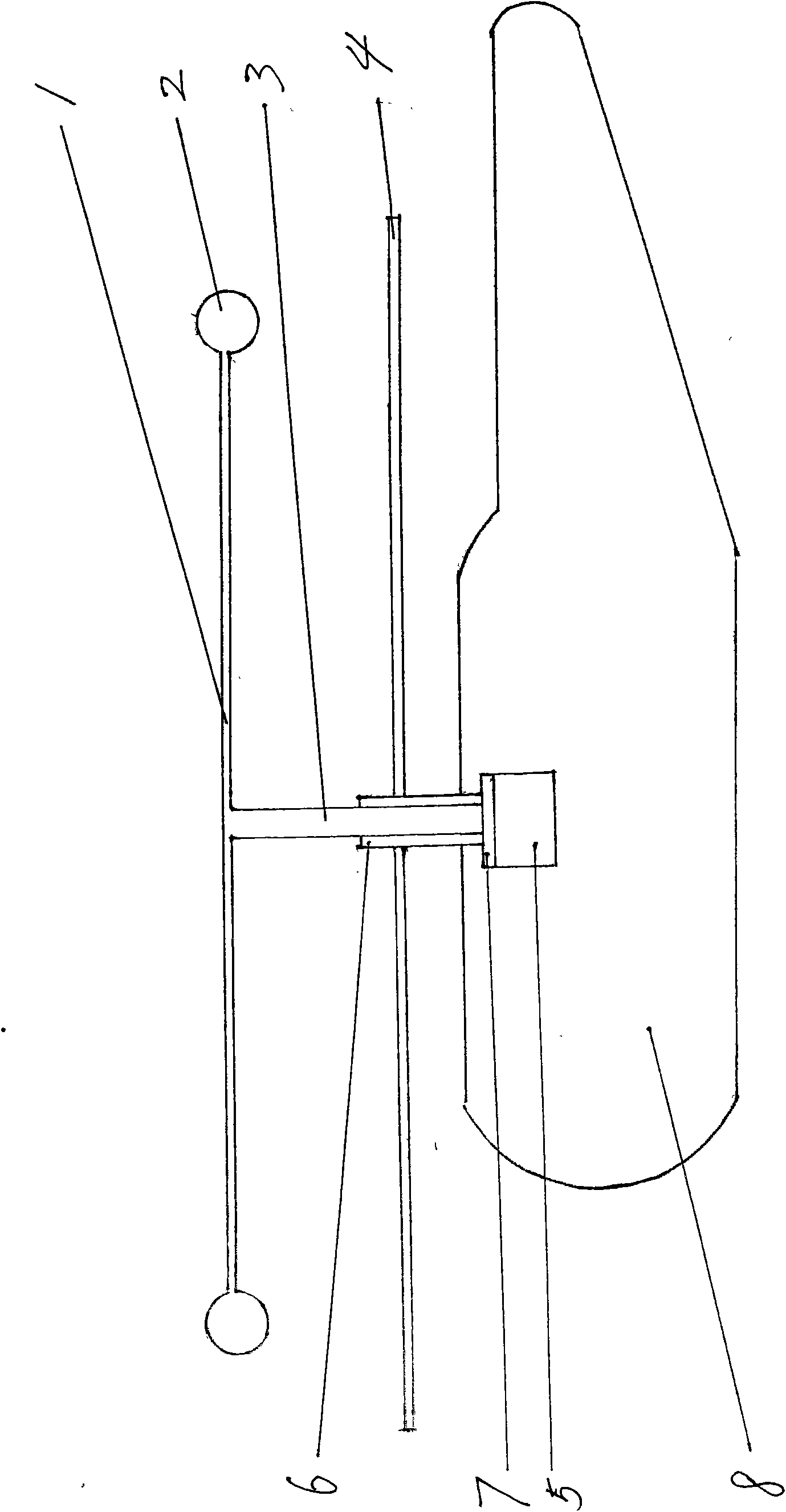

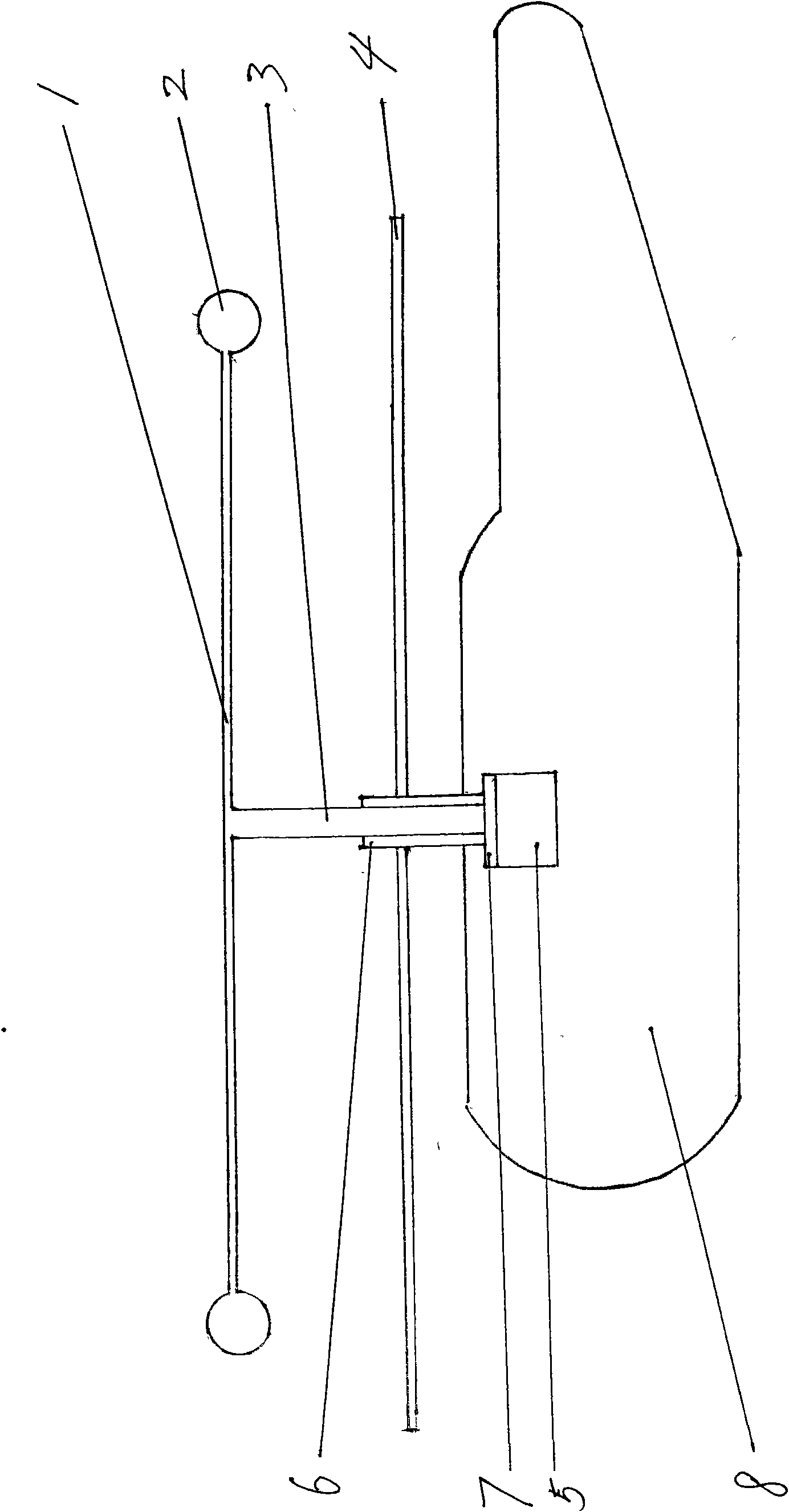

[0011] exist figure 1 Among them, 1. power wing, 2. jet wingtip device, 3. power wing output shaft, 4. main rotor, 5. reducer, 6. reducer output sleeve shaft, 7. clutch, 8. body.

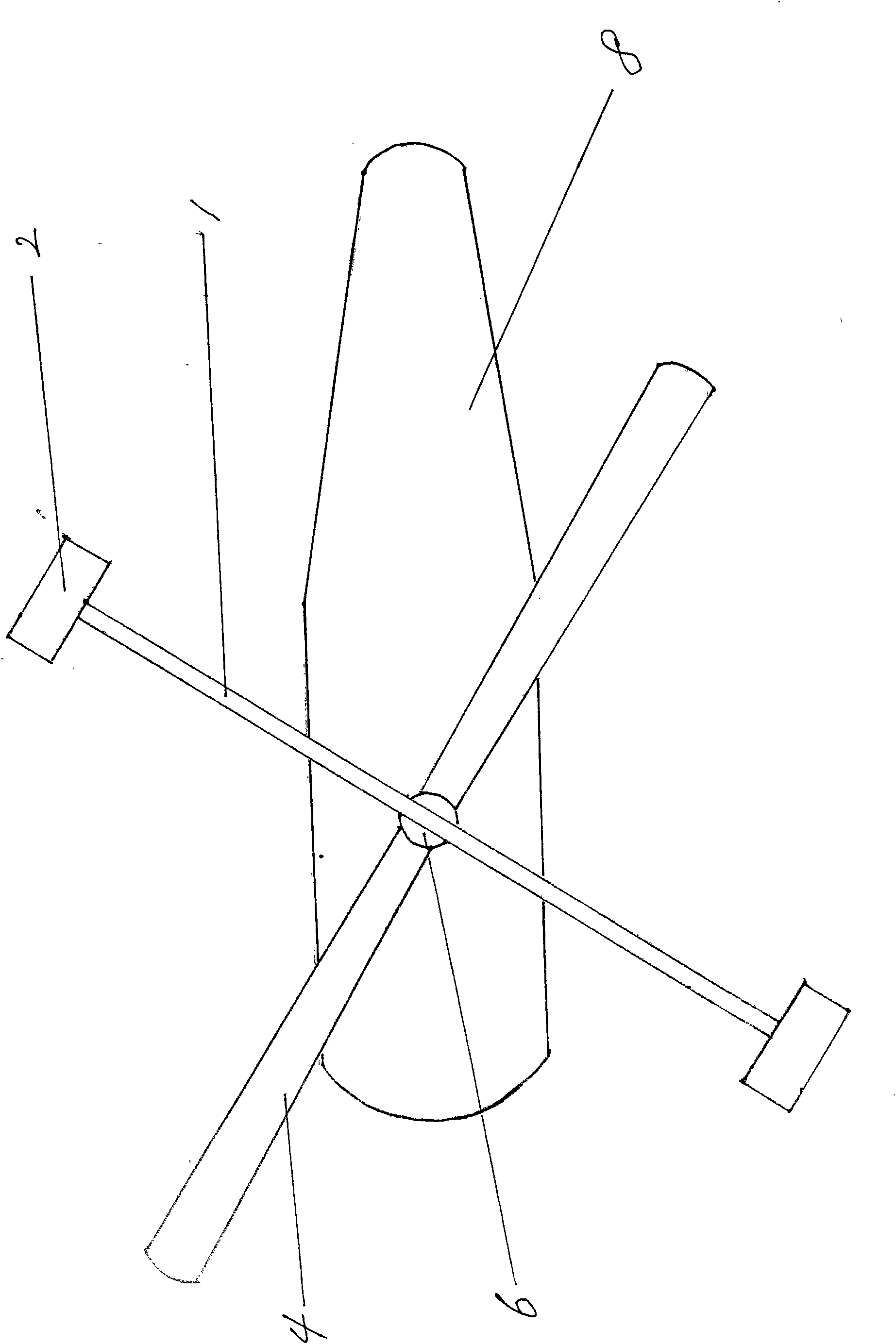

[0012] exist figure 2 Among them, 1. power wing, 2. jet wingtip device, 4. main rotor, 6. reducer output shaft, 8. body.

[0013] exist image 3 and Figure 4 Among them, the jet wing tip device (2) is arranged at both ends of the power wing (1), and the power wing output shaft (3) is located at the horizontal center point of the power wing (1) and fixed; the power wing output shaft (3) is connected with the reducer (5) is connected, and the output of reducer (5) is reducer output shaft (6), and reducer output sleeve shaft (6) links to each other with main rotor (4); Jet wing tip device (2) makes power wing (1 ) to rotate and drive the power wing output shaft (3) to rotate, the speed reducer (5) reduces the speed of the power wing output shaft (3) and outputs it to the speed reducer output slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com