Connection method of high voltage cable on electromotive

A technology for high-voltage cables and electric locomotives, which is applied to the equipment for connecting/terminating cables, and the connection and connection are completed by deformation. It can solve the problems of affecting the normal function of the locomotive, interference of electrical equipment, and unfavorable personal safety. It is convenient for equipment layout, Effects of reduced interference and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

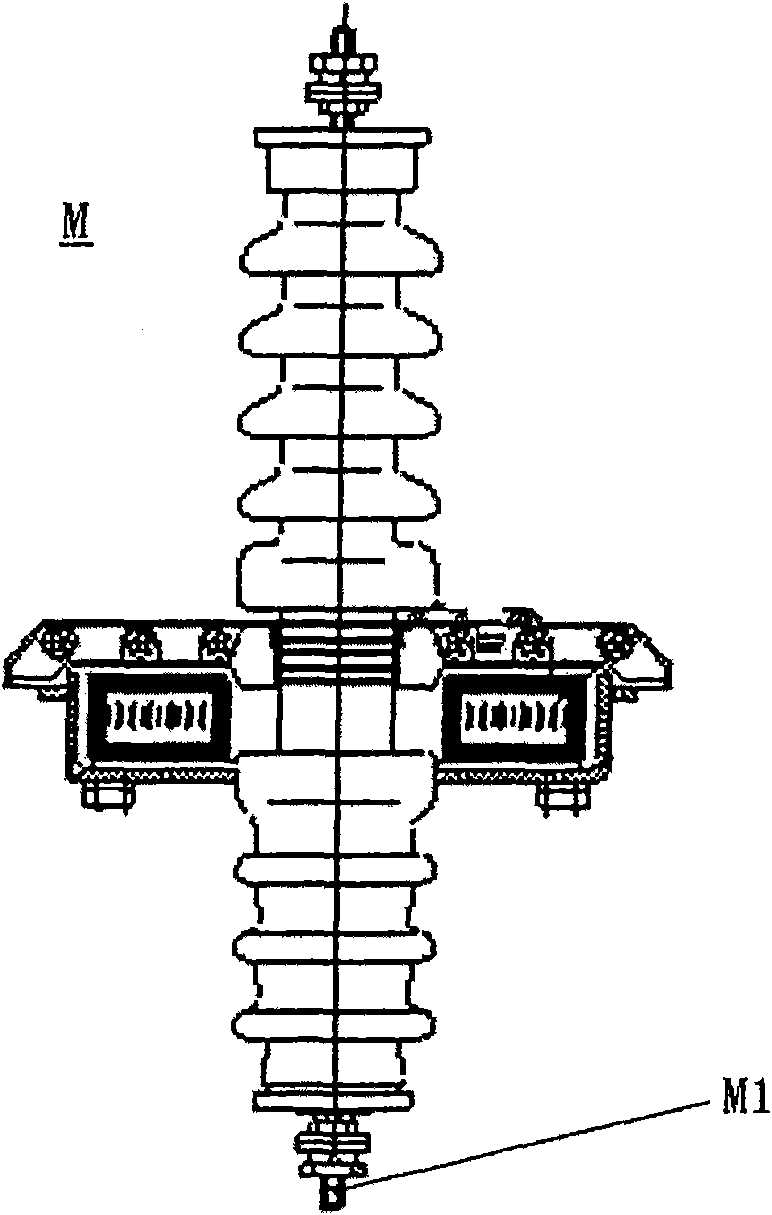

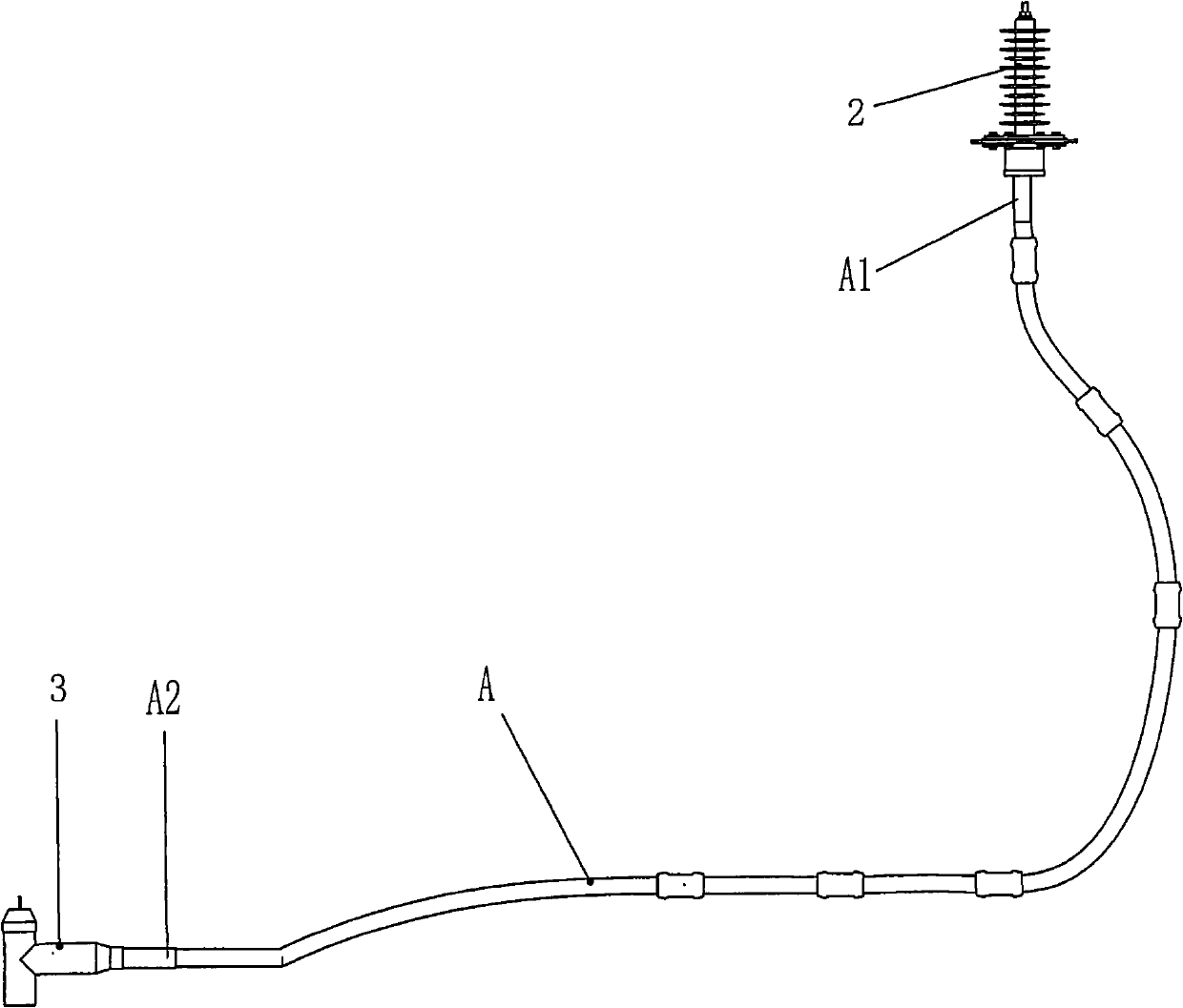

[0051] The invention provides a method for connecting high-voltage cables on an electric locomotive, which includes the following steps, such as image 3 , 4 Shown:

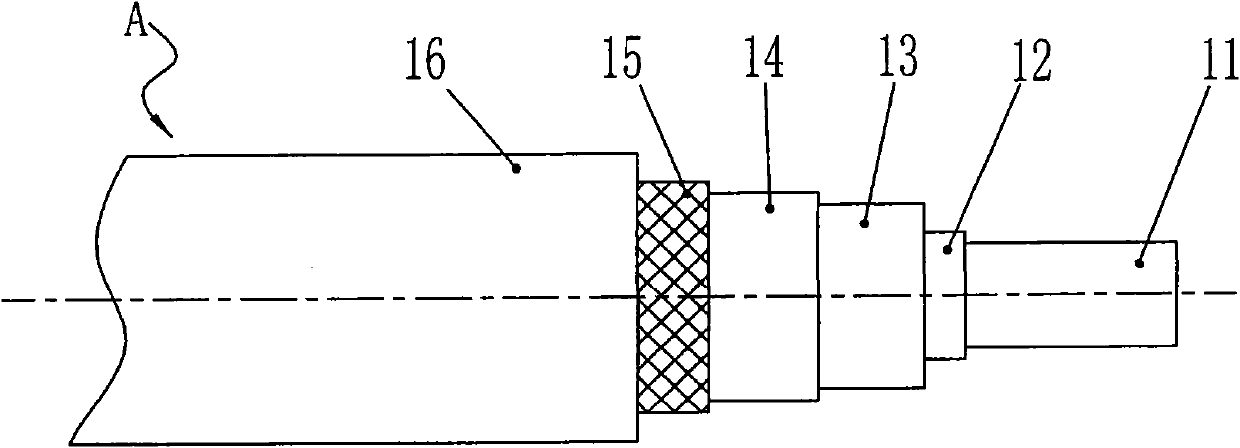

[0052] A. Provide a high-voltage cable A. The high-voltage cable A includes a conductor 11, a conductor semiconducting layer (also known as a conductor shielding layer) 12, an insulating layer 13, an insulating semiconducting layer (also known as an insulating shielding layer) 14, and a metal cable from the inside to the outside. Outer shielding layer 15 and outer sheath 16 . One end of the high-voltage cable A is the connection end A1 of the high-voltage bushing, and the other end is the connection end A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com