Vehicular metal absorber, vehicular bumper system, vehicular bumper absorber, and automobile bumper system

An absorber, metal technology, applied to bumpers, vehicle parts, vehicle safety arrangements, etc., can solve the problems of no convex and concave parts, complex structure, and inability to absorb collision energy, etc., to achieve the effect of protecting legs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

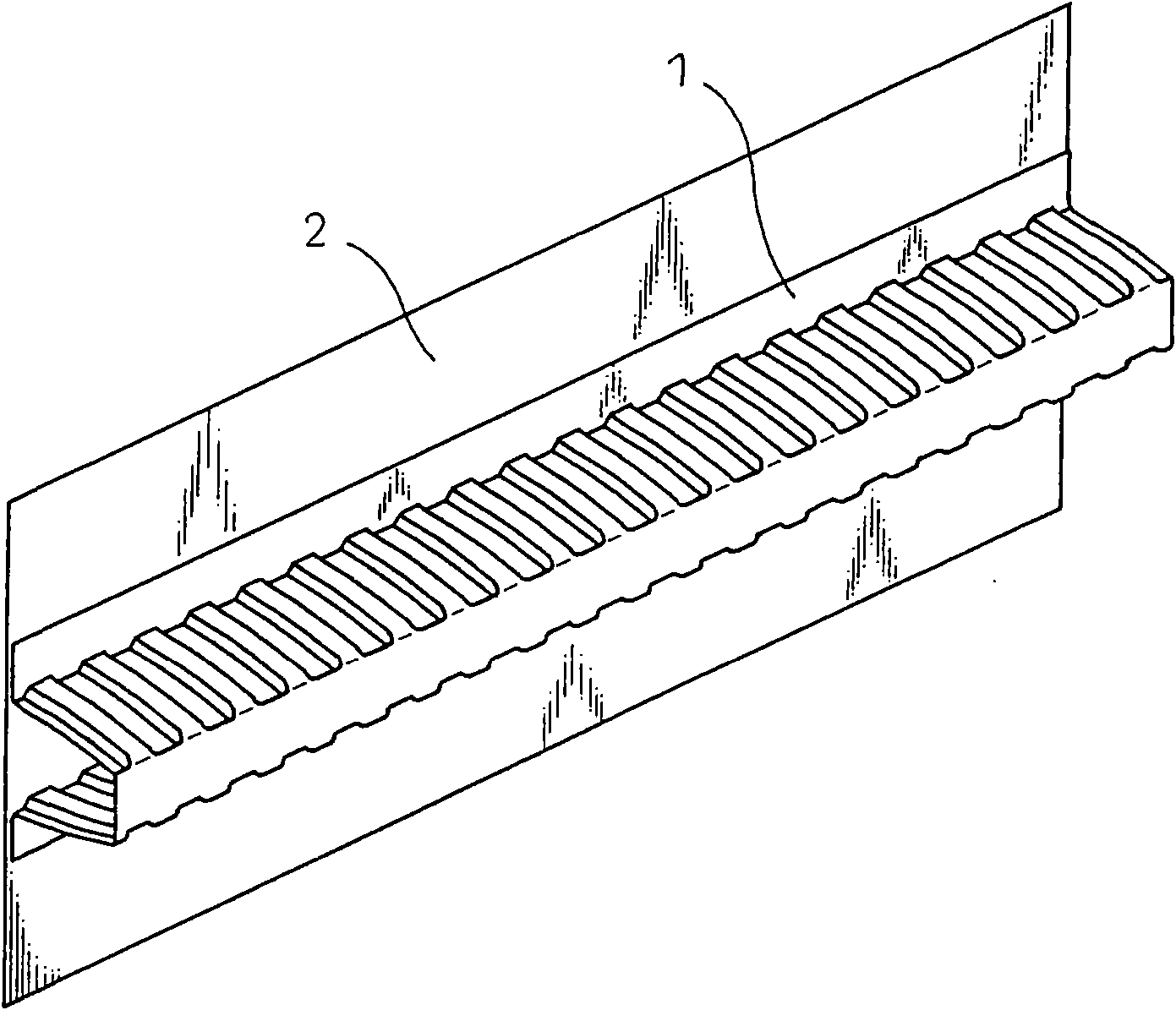

[0143] As the metal absorber of Example 1 of the present invention, a test body was formed by the following materials, working method, and shape.

[0144] Material: Use a thin steel plate with a tensile strength of 440 (MPa) and a plate thickness of 0.6 (mm).

[0145] Forming: using Figure 15 The die shown is formed into a roughly hat shape by pressing.

[0146] Shape: upper and lower dimensions (the maximum width of the upper web and lower web) 45 (mm),

[0147] Front-to-back dimensions (the front-to-back length of the upper web and the lower web) 50 (mm),

[0148] Right and left dimensions (car width direction length) 500 (mm),

[0149] The length (one side) of the upper flange and the lower flange is 20 (mm),

[0150] The length from the bent part in the middle of the upper flange and the lower flange to the central flange is 30 (mm),

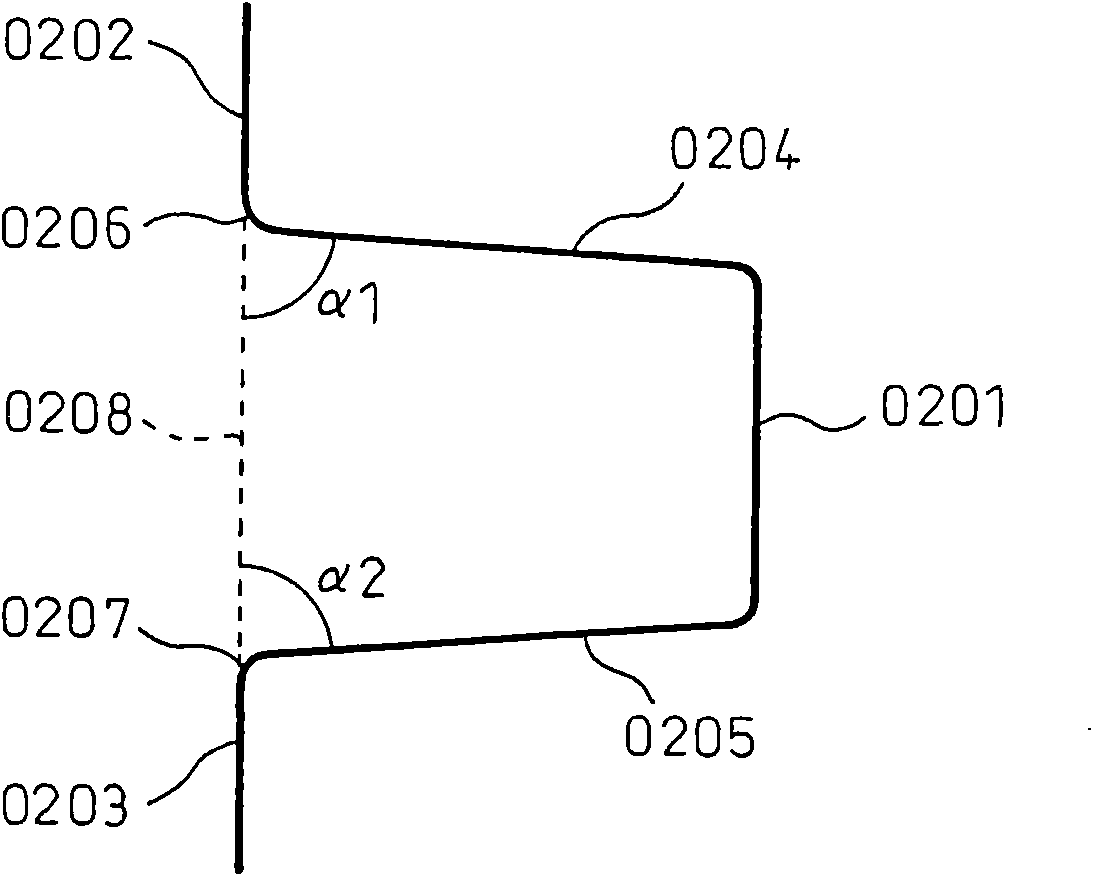

[0151] Flare angles of upper and lower webs toward the rear of the body:

[0152] Relative to the horizontal plane, from the upper w...

Embodiment 2

[0162] As the metal absorber of Example 2 of the present invention, a test body was formed with the following materials, working method, and shape.

[0163] Material: Use a thin steel plate with a tensile strength of 590 (MPa) and a plate thickness of 0.6 (mm).

[0164] Forming: Formed into a roughly hat shape by stamping.

[0165] Shape: upper and lower dimensions (the maximum width of the upper web and lower web) 45 (mm),

[0166] Front-to-back dimensions (the front-to-back length of the upper web and the lower web) 50 (mm),

[0167] Right and left dimensions (car width direction length) 500 (mm),

[0168] The length (one side) of the upper flange part and the lower flange part is 20 (mm),

[0169] Flare angle of upper web and lower web towards rear of vehicle body:

[0170] Relative to the horizontal plane, from the upper web and the lower web are 5 (degrees), ie α 1 : 85 (degrees), α 2 : 85 (degrees),

[0171] Rib width 25(mm), rib spacing (L) 50(mm),

[0172] Rib ...

Embodiment 3

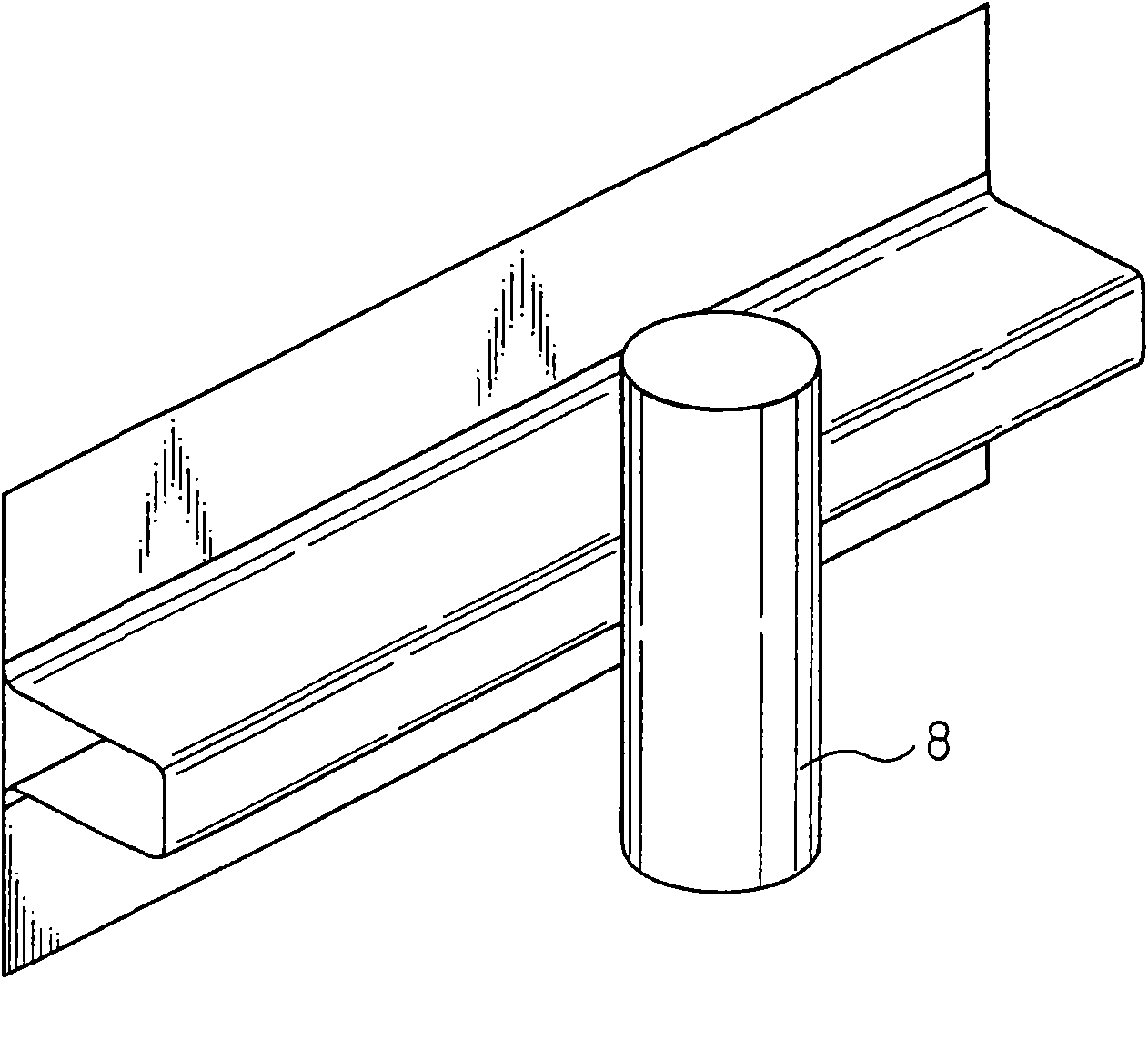

[0176] Hereinafter, the present invention will be specifically described using examples.

[0177]As the metal absorber of Example 3(a) of the present invention, a test body was formed with the following materials, working methods, and shapes.

[0178] Material: A thin steel plate with a tensile strength of 440 (MPa) and a plate thickness of 0.7 (mm) is used.

[0179] Forming: using Figure 15 The die shown is formed by stamping as Figure 22 Approximate hat shape shown in (a).

[0180] Shape: upper and lower dimensions (the maximum width of the upper web and lower web) 45 (mm),

[0181] Front-to-back dimensions (the front-to-back length of the upper web and the lower web) 50 (mm),

[0182] Right and left dimensions (car width direction length) 500 (mm),

[0183] The length (one side) of the upper flange and the lower flange is 20 (mm),

[0184] The length from the bent part in the middle of the upper flange and the lower flange to the central flange is 25 (mm),

[0185]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com