Folding container

A container and folding technology, applied in the field of folding containers, can solve the problems of slowing down the friction loss conversion process, and achieve the effects of reducing friction loss, compensating for friction force, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

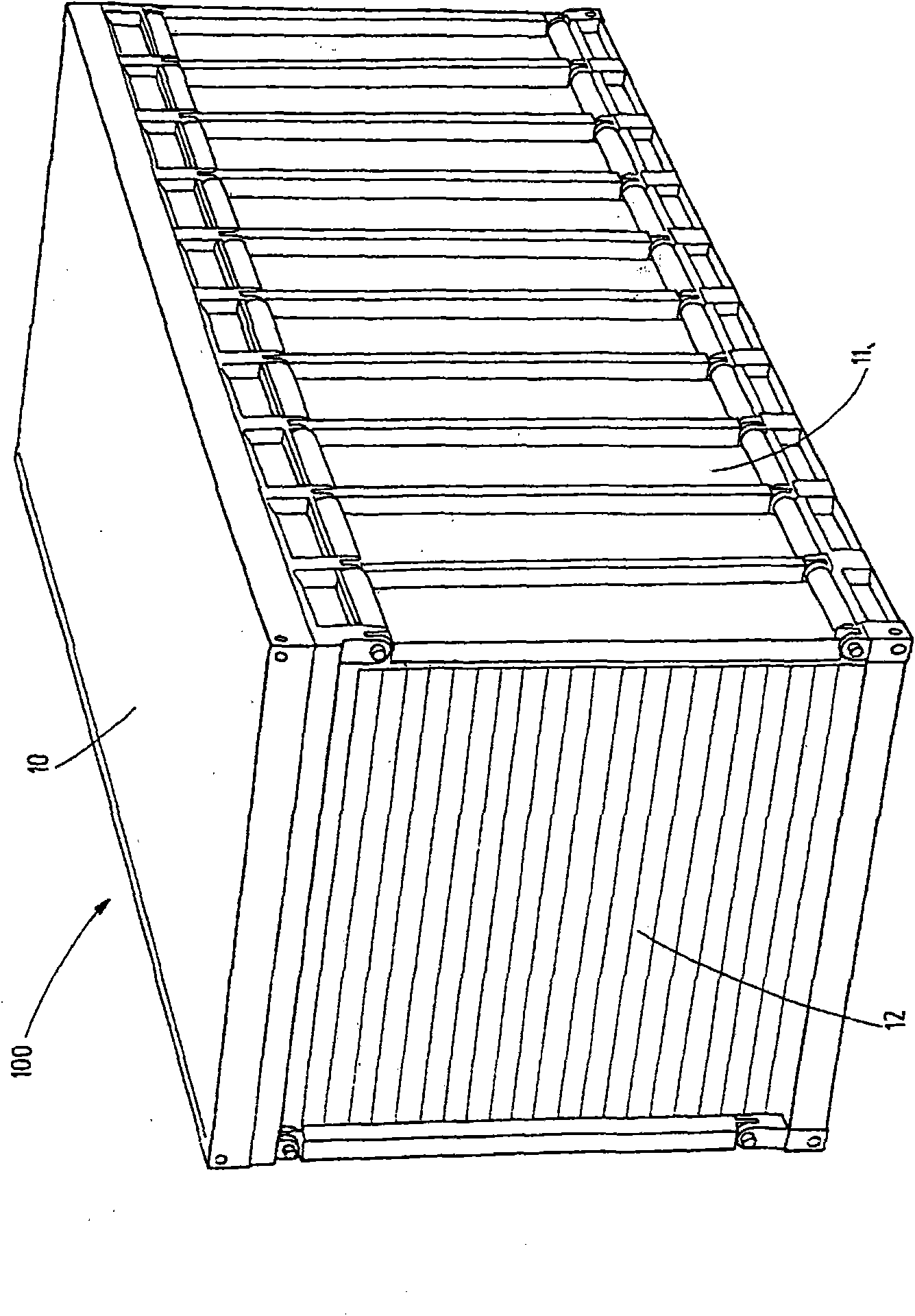

[0022] figure 1 A collapsible container, referenced 100, according to the present invention is shown.

[0023] The surrounding walls of the folding container 100 (front end wall 12 and rear end wall, side walls 11, 13 and roof 10) are made of a composite material which is light in weight.

[0024] At corner points, there is always a perforated plate or a lifting eye embedded in the roof 10, so that the container 100 can be lifted by conventional spreaders and the container can be released by means of fixtures in the floor 20, enabling the roll guides.

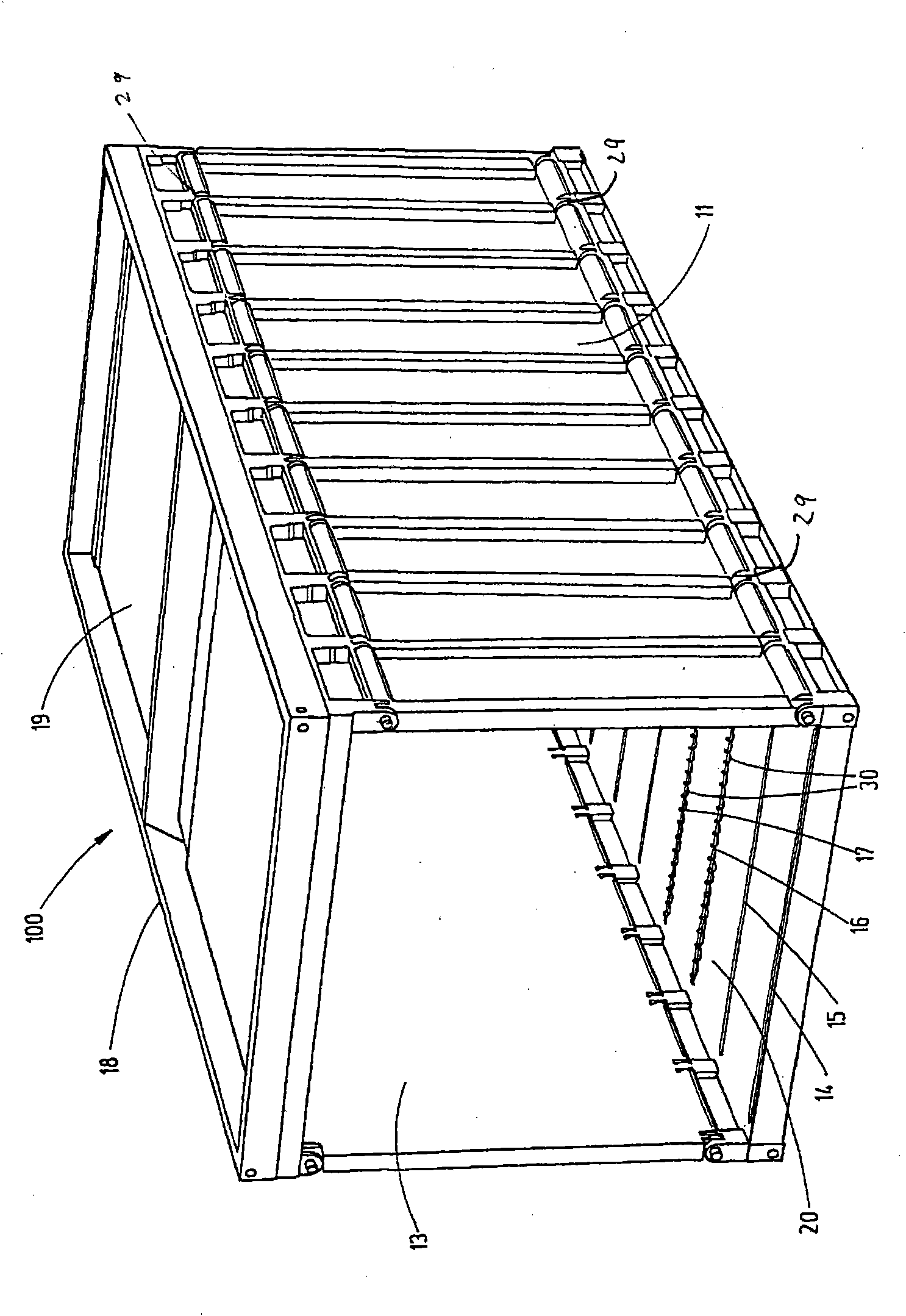

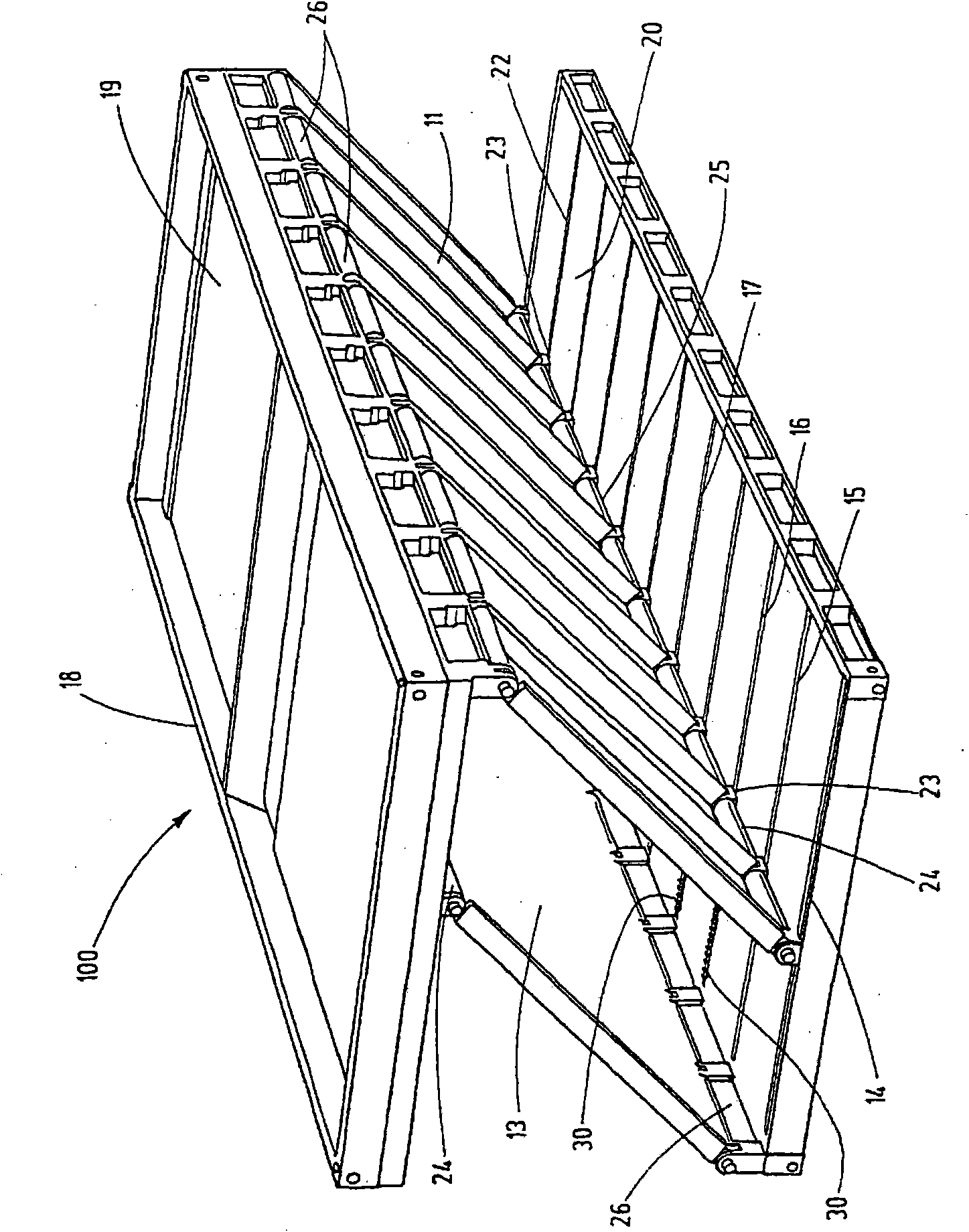

[0025] The collapsible container 100 has a first side wall 13 (see figure 2 ) and a second side wall 11, a top cover 10, a bottom plate 20 (see figure 2 ) and a front end wall 12 and a rear end wall. Both the front end wall 12 and the back end wall are designed in the form of rolling shutter doors.

[0026] figure 2 The folding container according to the invention is shown with the front end wall 12 opened. The bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com