Press felt for papermaking

A technology for pressing felts and batts, applied in papermaking, papermaking, textiles and papermaking, etc., can solve problems such as compression fatigue, maintain smoothness, suppress rewetting, and improve abrasion resistance and compression fatigue resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

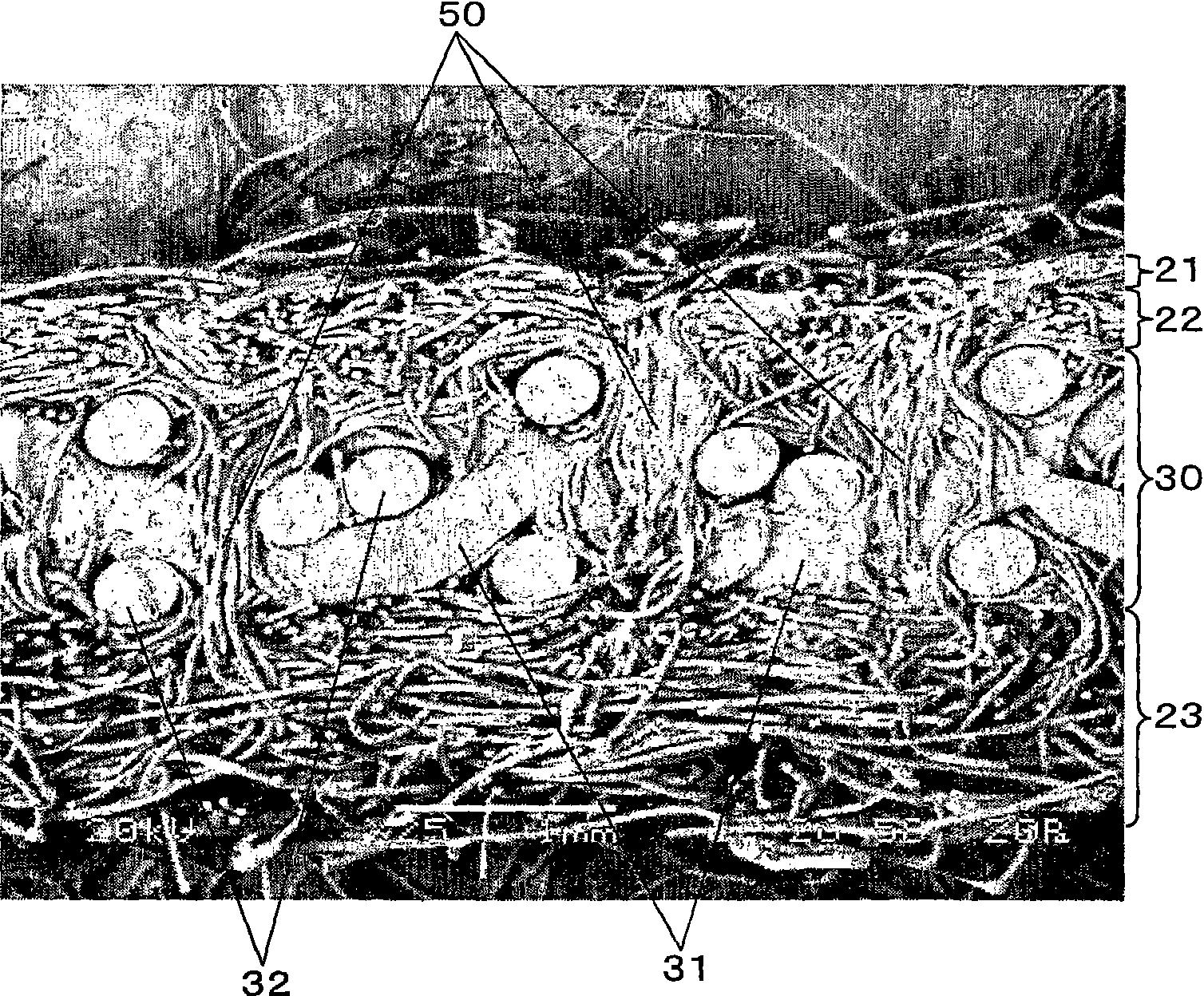

[0057] In addition, as the first embodiment of the present invention, the fibers contained in the base side batt layer 22 use so-called core-sheath composite fibers in which the sheath is melted by heat treatment but the core is not. However, the core-sheath composite fibers may be replaced with Fully fused fibers are used, or both core-sheath composite fibers and fully fused fibers may be used together.

[0058] Here, the so-called full-melt fiber refers to a fiber in which all components are made of low-melting-point materials and are completely melted at a relatively low temperature. When fibers containing fully melted fibers are included in the base side batt, compared to when the above-mentioned core-sheath composite fibers are included, the action of hot pressing during the production of felts is slightly eased, since only the side of the fully melted fibers can be melted, so It is possible to thermally bond napped fiber bundles of fully fused fibers in a columnar shape....

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com