Super absorbent polymer and preparation method for the same

A super-absorbent, polymer technology that is used in absorbent pads, bandages, medical science, etc., and can solve problems such as not raised

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

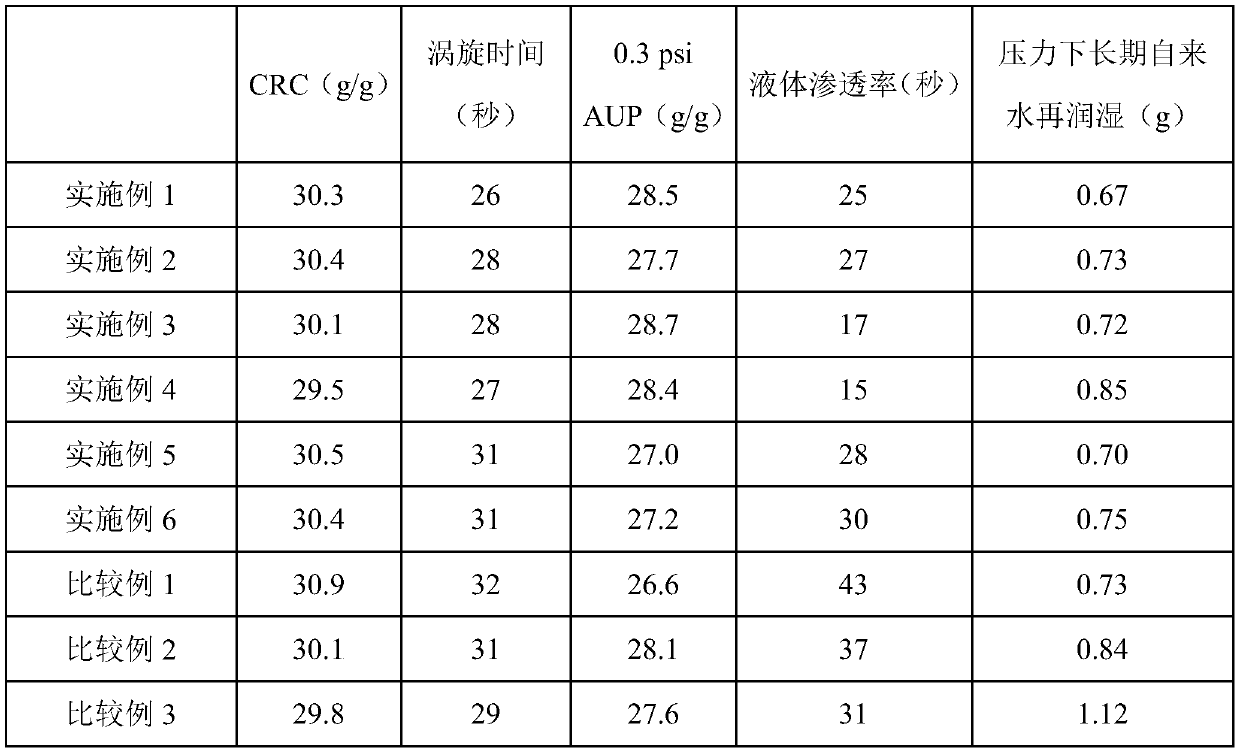

Examples

preparation example Construction

[0024] A method of preparing a superabsorbent polymer according to one embodiment of the present invention comprises the following steps:

[0025] preparing a base resin by cross-linking polymerization of an acrylic acid-based monomer having at least partially neutralized acid groups and an internal cross-linking agent (step 1);

[0026] Mixing of the base resin with inorganic fillers and epoxy-based surface crosslinkers, where the base resin is first dry blended with the inorganic fillers and subsequently surface-crosslinked by dissolving the epoxy-based surface crosslinkers in water Epoxy-based surface crosslinker mixing in solution (step 2); and

[0027] Surface modification of the base resin (step 3) by raising the temperature of the mixture of step 2,

[0028] Wherein the epoxy compound-based surface crosslinking agent comprises a first epoxy compound crosslinking agent having an epoxy equivalent of 100 g / eq or greater to less than 130 g / eq and a second epoxy compound ha...

Embodiment 1

[0126] (1) Preparation of base resin

[0127] 518 g of acrylic acid, 3.2 g of polyethylene glycol diacrylate (polyethylene glycol (400) diacrylate) and 0.04 g of diphenyl(2,4,6-trimethylbenzoyl)-phosphine oxide were added to Place in a 3 L glass vessel equipped with a stirrer, nitrogen feeder and thermometer and dissolve. Then, 822.2 g of a 24.5% sodium hydroxide solution was added thereto, and nitrogen gas was continuously injected to prepare a water-soluble unsaturated monomer aqueous solution. The aqueous solution of the water-soluble unsaturated monomer was cooled to 40°C. 500 g of this aqueous solution was fed into a stainless steel container with a width of 250 mm, a length of 250 mm and a height of 30 mm, and was irradiated by UV (exposure dose: 10 mV / cm 2 ) was subjected to UV polymerization for 90 seconds to obtain an aqueous gel polymer. The aqueous gel polymer thus obtained was pulverized to a size of 2 mm*2 mm, spread on a stainless steel wire mesh with a hole s...

Embodiment 2

[0131] A superabsorbent polymer powder was obtained in the same manner as in Example 1, except that in step (2), glycerol polyglycidyl ether was used in an amount of 0.005 parts by weight relative to 100 parts by weight of the base resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com