Superabsorbent polymer and method for preparing same

A technology of superabsorbent and polymer, applied in the field of superabsorbent polymer and its preparation, capable of solving unasked problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

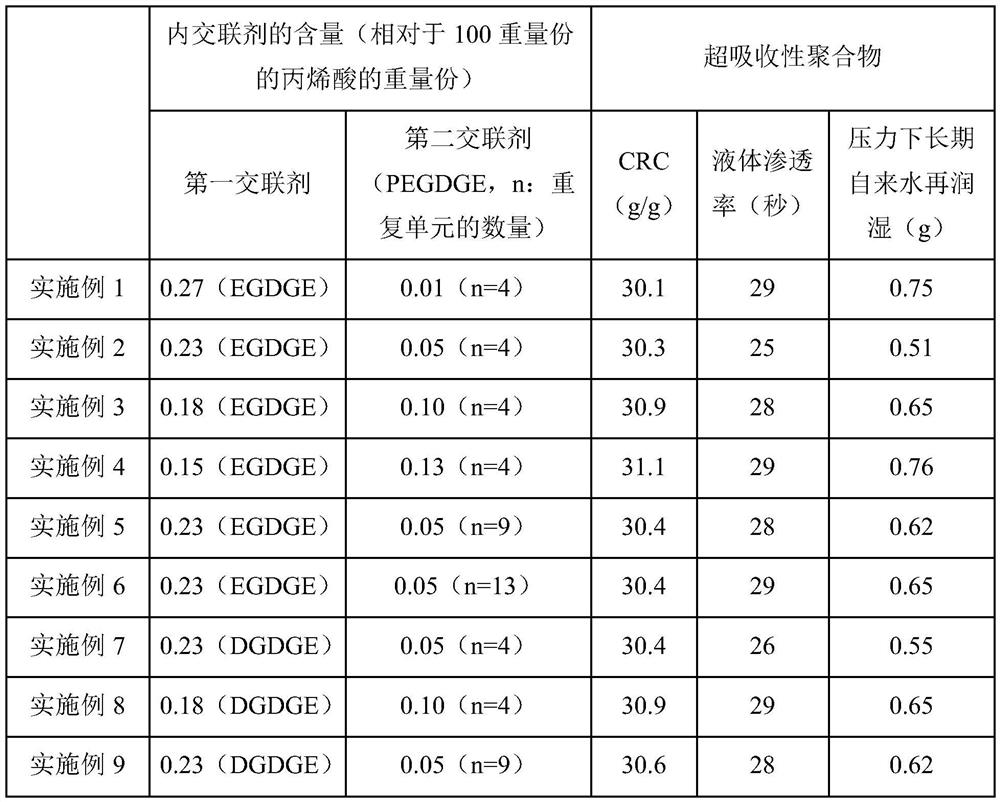

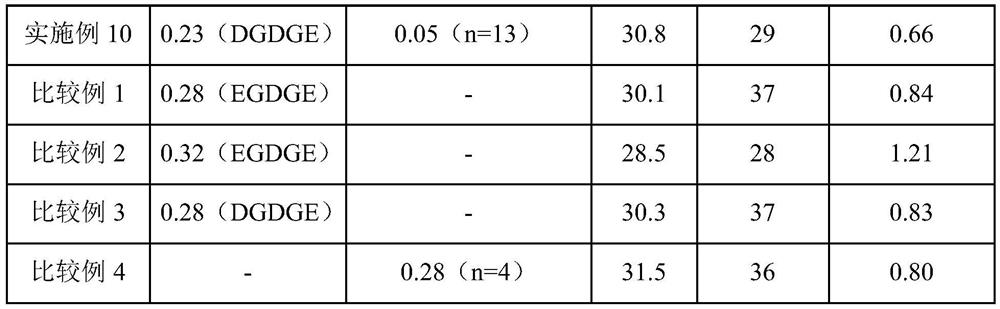

Examples

preparation example Construction

[0022] A method of preparing a superabsorbent polymer according to an embodiment of the present invention may include the following steps:

[0023] preparing a base resin in which an acrylic-based monomer having at least partially neutralized acid groups and an internal crosslinking agent are crosslinked; and

[0024] heating the base resin in the presence of a surface crosslinking agent for surface modification of the base resin,

[0025] Wherein the internal crosslinking agent comprises a first epoxy crosslinking agent having an epoxy equivalent weight of 100 g / equivalent or greater to less than 130 g / equivalent and a second epoxy crosslinking agent having an epoxy equivalent weight of 130 g / equivalent or greater .

[0026] In the specification of the present invention, "base resin" or "base resin powder" means a polymer in the form of particles or powder obtained by polymerizing a water-soluble ethylenically unsaturated monomer followed by drying and pulverization. "Base ...

Embodiment 1

[0122] (1) Preparation of base resin

[0123] 518g of acrylic acid, 1.40g (0.27 parts by weight relative to 100 parts by weight of acrylic acid) ethylene glycol diglycidyl ether (EGDGE, epoxy equivalent weight is 113g / equivalent), 0.052g (0.27 parts by weight relative to 100 parts by weight of acrylic acid) 0.01 parts by weight) poly(ethylene glycol) diglycidyl ether (PEGDGE, epoxy equivalent weight 185 g / equivalent) with 4 ethylene glycol repeating units and 0.04 g diphenyl (2,4,6-trimethyl (((2)-benzoyl)-phosphine oxide was added to a 3 L glass vessel equipped with a stirrer, nitrogen feeder, and thermometer and dissolved. Then, 822.2 g of a 24.5% sodium hydroxide solution was added thereto, and nitrogen gas was continuously injected to prepare a water-soluble unsaturated monomer aqueous solution. The aqueous solution of the water-soluble unsaturated monomer was cooled to 40°C.

[0124] 500 g of this aqueous solution was fed into a stainless steel container with a width of...

Embodiment 2

[0128] Superabsorbent polymer powder was obtained in the same manner as in Example 1, except that, in step (1), 0.23 parts by weight of ethylene glycol diglycidyl ether and 100 parts by weight of acrylic acid were used. 0.05 parts by weight of poly(ethylene glycol) diglycidyl ether having 4 ethylene glycol repeating units.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com