Method for preparing superabsorbent resin, and superabsorbent resin

A superabsorbent and polymer technology, applied in the field of superabsorbent polymers, can solve the problems of deterioration of physical properties, reduce the degree of polymerization of superabsorbent polymers, etc., and achieve improved absorption rate, excellent dispersion stability and compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

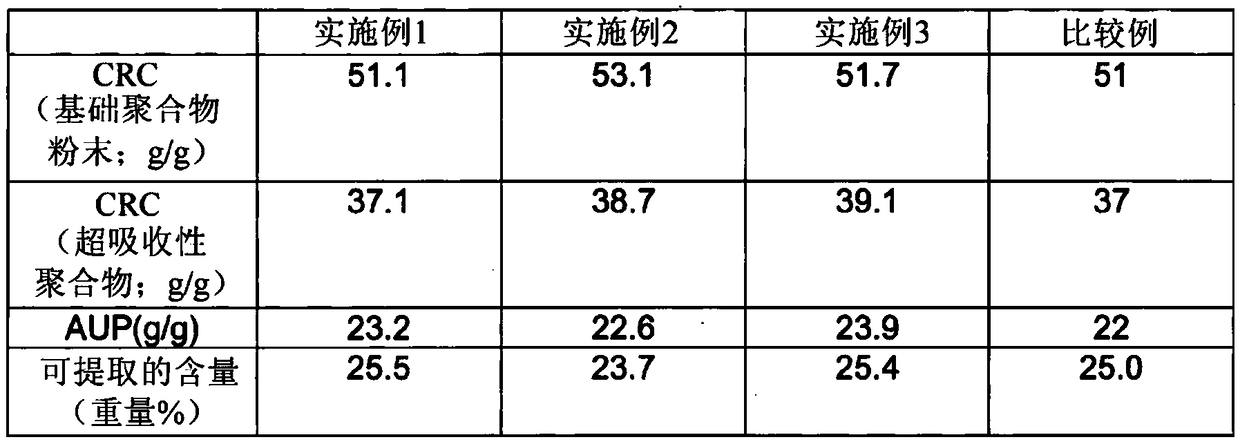

[0131] Example 1: Preparation of superabsorbent polymer

[0132] Use 3M TM Glass hollow particles iM30K (particle size: 15.3 μm (D50), density: 0.6 g / cc).

[0133] 537.45g of acrylic acid, 0.32g of glass hollow particles (based on 100 parts by weight of monomer, 0.06 parts by weight), 0.86g of polyethylene glycol diacrylate (Mw=598) as a crosslinking agent, 653.17g of 30% caustic soda (NaOH ), 0.04 g of diphenyl (2,4,6-trimethylbenzoyl)-phosphine oxide as a UV initiator, 1.07 g of sodium persulfate and 206.41 g of water were mixed to prepare an acrylic acid monomer concentration of 36.7% by weight (Neutralization degree of acrylic acid: 70 mol%).

[0134] Subsequently, the monomer composition was stirred at 300 rpm for 25 seconds and foamed.

[0135] Then, the monomer composition is fed to a continuously moving conveyor belt reactor through a feeder, and then is irradiated with UV rays (irradiation dose: 2mW / cm2) by a UV irradiation device. 2 ) for 2 minutes to perform U...

Embodiment 2

[0140] Example 2: Manufacture of superabsorbent polymer

[0141] Use 3M TM Glass hollow particles iM30K (particle size: 15.3 μm (based on D50), density: 0.6 g / cc).

[0142]A superabsorbent resin having a particle size of 150 μm to 850 μm of Example 2 was produced in the same manner as in Example 1 except that 0.8 g of glass hollow particles (0.15 parts by weight based on 100 parts by weight of the monomer) was used.

Embodiment 3

[0143] Example 3: Manufacture of superabsorbent polymer

[0144] Use 3M TM Glass hollow particles iM30K (particle size: 15.3 μm (based on D50), density: 0.6 g / cc).

[0145] A superabsorbent resin having a particle size of 150 μm to 850 μm in Example 3 was produced in the same manner as in Example 1, except that 2.68 g of glass hollow particles (0.5 parts by weight based on 100 parts by weight of the monomer) were used and The foaming time was changed to 22 seconds.

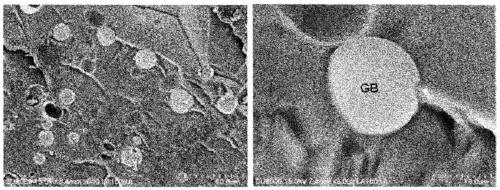

[0146] An electron micrograph of the superabsorbent resin produced in Example 3 is shown in figure 1 , it was confirmed that the hollow glass particles were uniformly dispersed in the base resin powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com