Photocurable composition and photocurable layer formed from the same

A photocurable and composition technology, which is applied in the field of photocurable composition and photocurable film, can solve the problems of fine patterning limitation, composition viscosity increase, etc., and achieve the effect of excellent gas and moisture barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

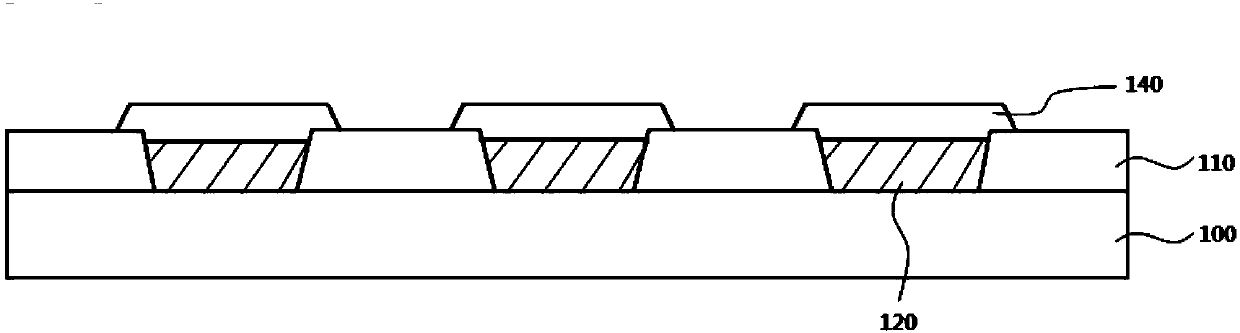

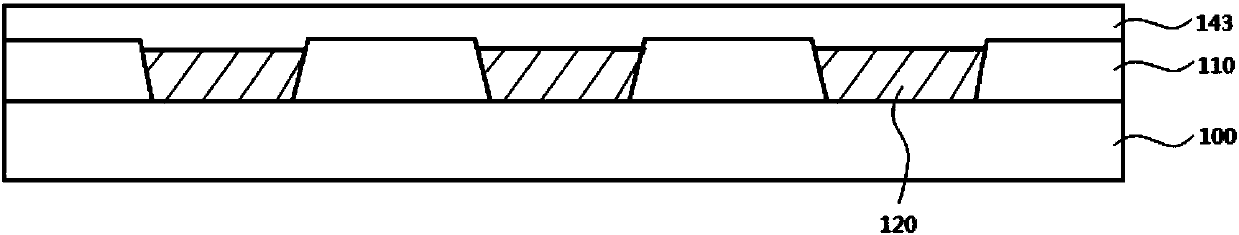

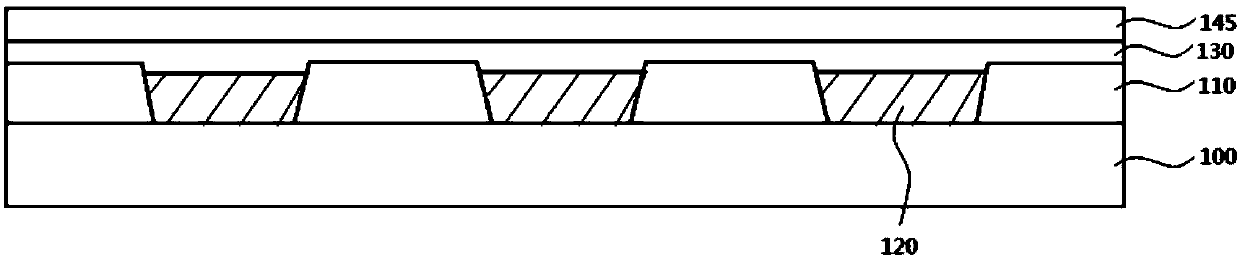

Image

Examples

experiment example

[0245] The compositions in Tables 1 and 2, or coating films formed from these compositions, and photocured films were evaluated for viscosity, applicability, pencil hardness, and oxygen inhibition by the evaluation methods described later. The evaluation results are shown in Table 3 below.

[0246] (1) Viscosity measurement

[0247] The viscosity of each composition of an Example and a comparative example was measured using the viscometer (DV3T, manufactured by Brookfield Co., Ltd.) (measurement condition: rotation speed 20 rpm / 25 degreeC).

[0248] (2) Coatability evaluation

[0249] Each composition of the Examples and Comparative Examples was spin-coated on a silicon (Si) sheet cut into a size of 50 mm×50 mm to form a coating film so as to have a thickness of 3.0 μm. After spin coating, it was left to stand for 5 minutes, the shape of the coating film was observed, and applicability was evaluated as follows.

[0250]

[0251] ○: The coating film is spread evenly an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com