Handle of fishing rod

A technology for fishing rods and handles, applied in fishing rods, fishing, decorative arts, etc., can solve the problems of difficulty, increased weight of fishing rods, easy rust and disassembly of metal tail parts, etc., and achieve the effect of solving rust problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

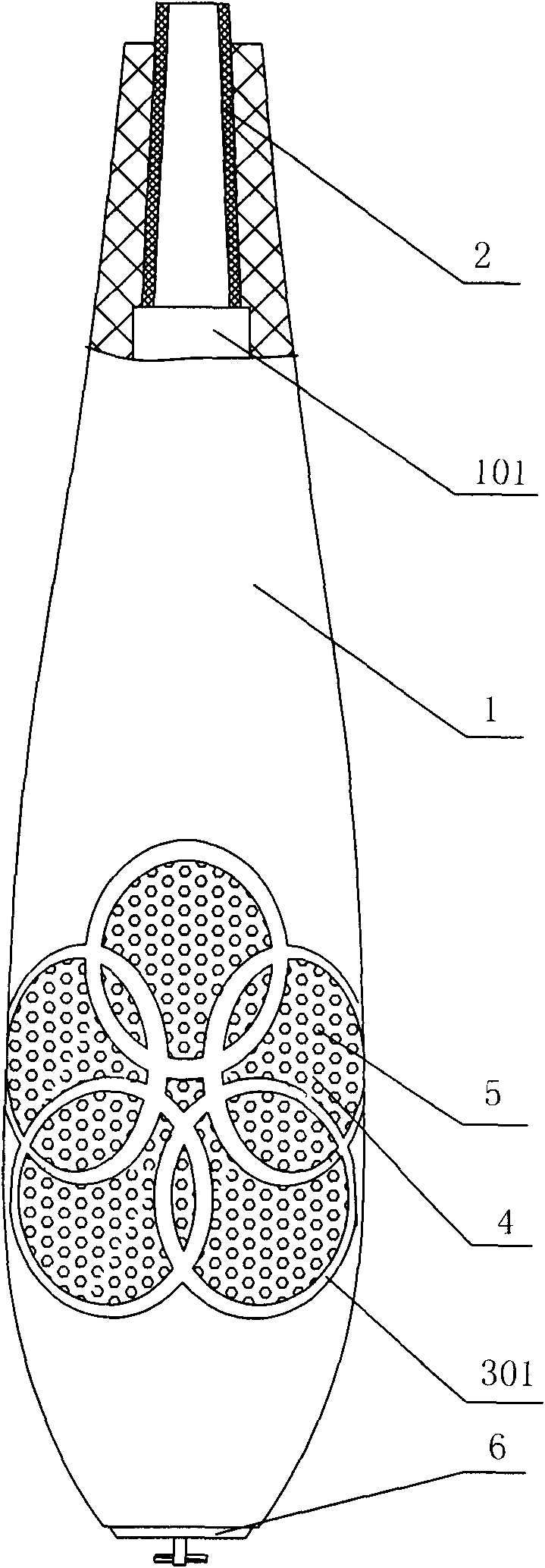

[0018] figure 1 A schematic diagram of the structure of the handle of a platform fishing rod is given in .

[0019] exist figure 1 Among them, a fishing rod handle includes a handle body 1 .

[0020] Such as figure 1 As shown, the handle body 1 is in the shape of a spindle and is held by fishermen. In order to increase the grade of its products, the handle body uses essential materials to highlight its natural and elegant features.

[0021] figure 1 In the inner cavity 101 through which the handle body 1 penetrates, a set of joints 2 is inserted and fixed. It should be pointed out that the socket 2 can adopt a scheme in which the taper of its inner diameter is consistent with the taper of the outer diameter of the rear end of the other rod joints that are matched with it, and the other rod joints are connected with it by pulling. The sleeve joint 2 can also adopt a scheme in which the taper of its outer diameter is consistent with the taper of the inner diameter of the r...

Embodiment 2

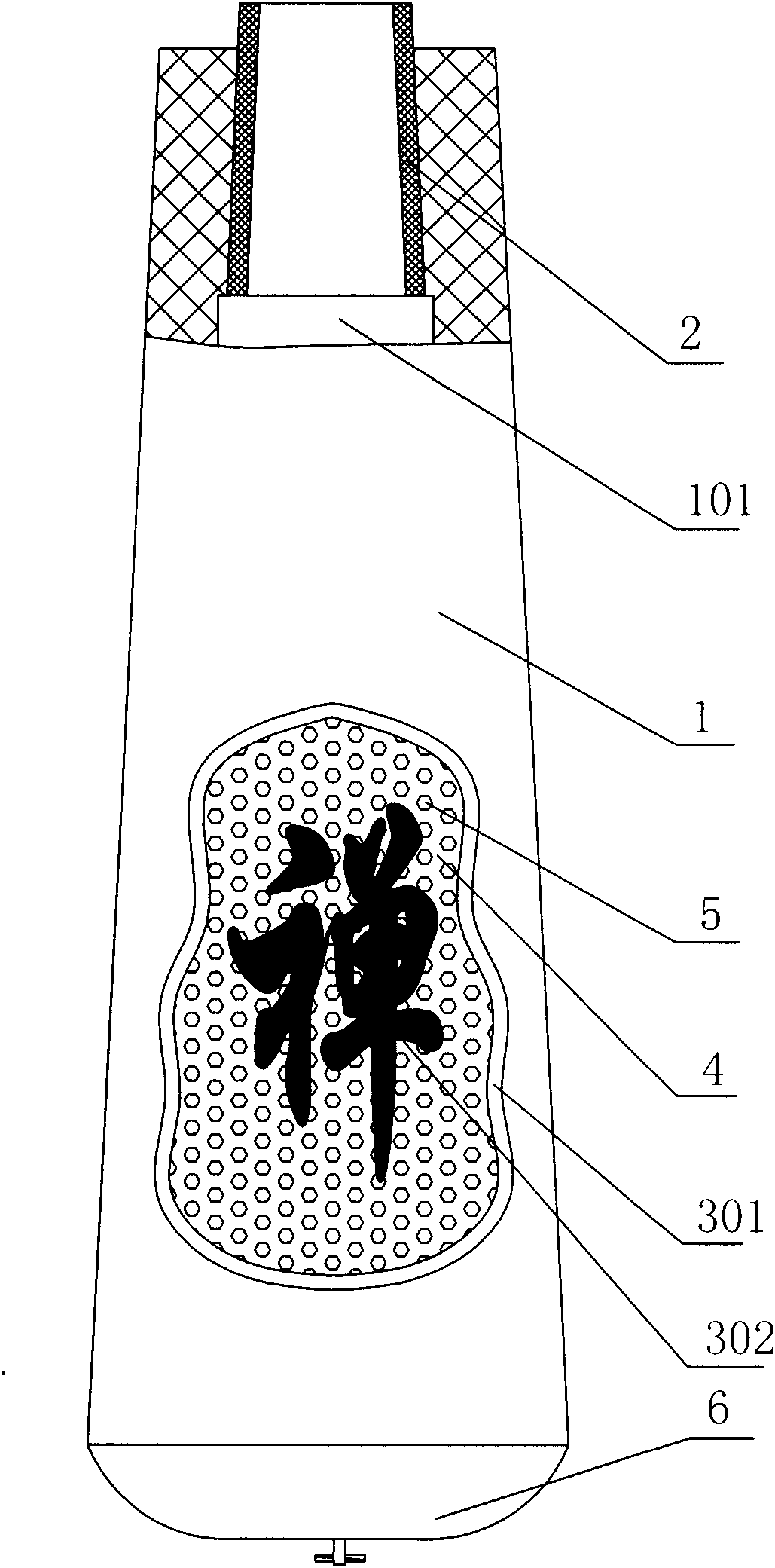

[0030] figure 2 Provided is a sea pole type fishing rod handle.

[0031] exist figure 2 Among them, a fishing rod handle includes a handle body 1 .

[0032] Such as figure 2 As shown, the handle body 1 is a slightly tapered cone, which is grasped by fishermen. In order to increase its anti-corrosion performance and product grade, the handle body 1 can be made of plastic material, and its appearance can be simulated to highlight its natural and noble appearance.

[0033] figure 2 In the inner cavity 101 through which the handle body 1 penetrates, a set of joints 2 is inserted and fixed. The bushing 2 adopts the scheme that the taper of its inner diameter is consistent with the taper of the outer diameter of the rear end of other pole joints connected with it, so that the other pole joints and the bushing 2 are pulled and connected.

[0034] exist figure 2 Among them, a tail piece 6 is assembled at the tail of the handle body 1, and the tail piece 6 is made of plasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com