Connector and O-shaped ring mounting groove structure for sealing end face

An end-face sealing and connector technology, which is applied in the field of connectors and the O-ring installation groove structure for end-face sealing, achieves the effects of reducing production processes, improving processing technology, and easily ensuring reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

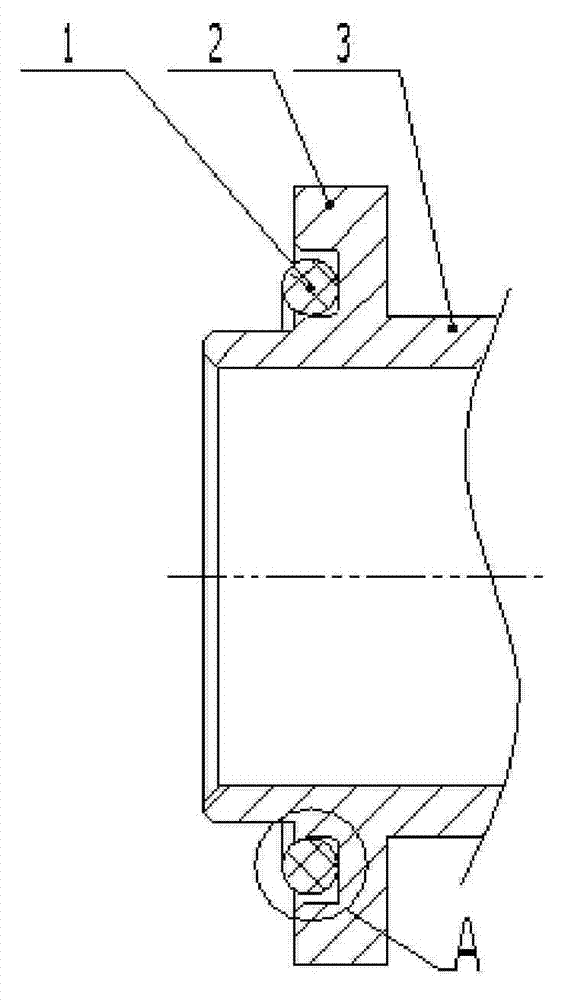

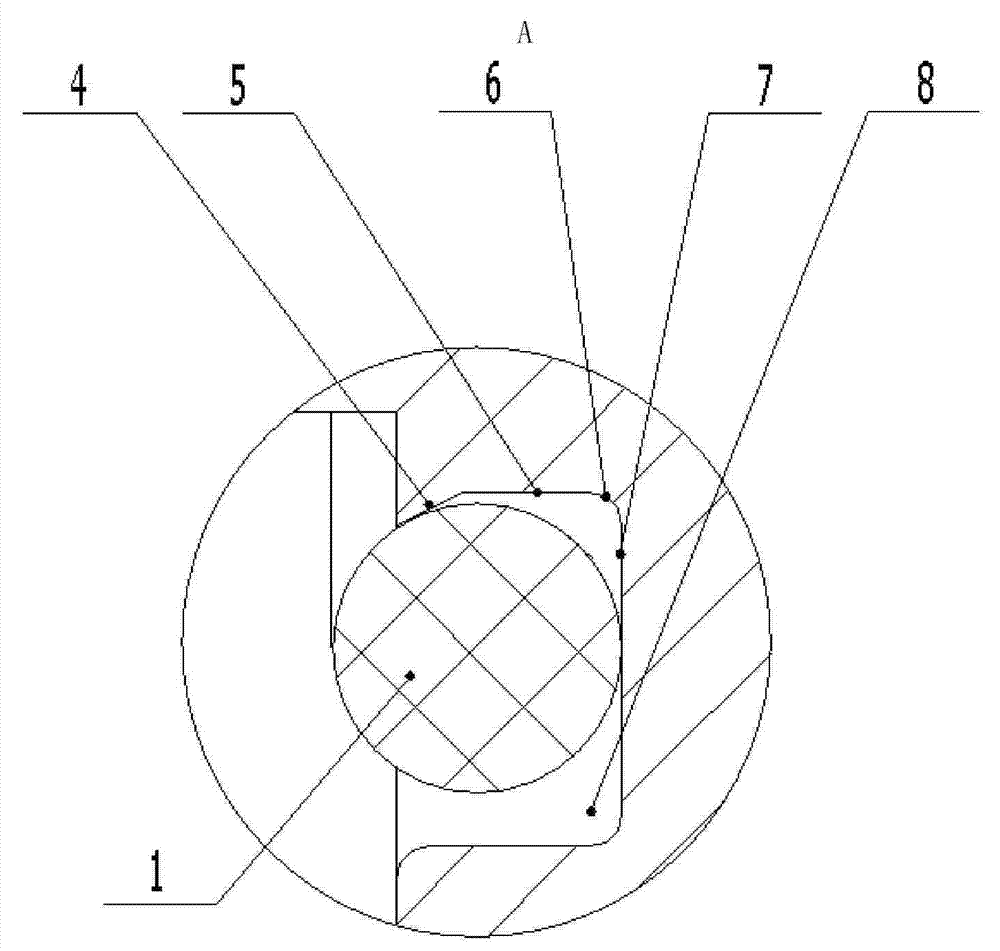

[0016] exist figure 1 , figure 2 Among them, the connector housing 3 is provided with a flange 2, and the sealing end surface of the flange 2 is provided with an O-ring installation groove 8, and the wall surface of the inner groove wall with a smaller diameter of the O-ring installation groove 8 It is composed of a cylindrical surface 5 close to the bottom surface of the groove and a truncated cone surface 4 close to the groove notch. The truncated cone surface 4 is transitionally connected with the cylindrical surface 5 through its small end, and the large end of the truncated cone surface 4 extends to The notch edge of the groove 8 and the truncated cone surface 4 are used to prevent the O-ring 1 from coming out of the O-ring installation groove 8 . The wall surface of the inner and outer groove walls of the O-ring installation groove 8 and the bottom surface 7 are transitioned through the arc surface 6 . The height of the cylindrical surface 5 near the bottom of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com