Detachable pressing cutter device

A detachable knife device technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of unstable structure of the press knife device, uneven thermal expansion and contraction, skewed pressure head, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

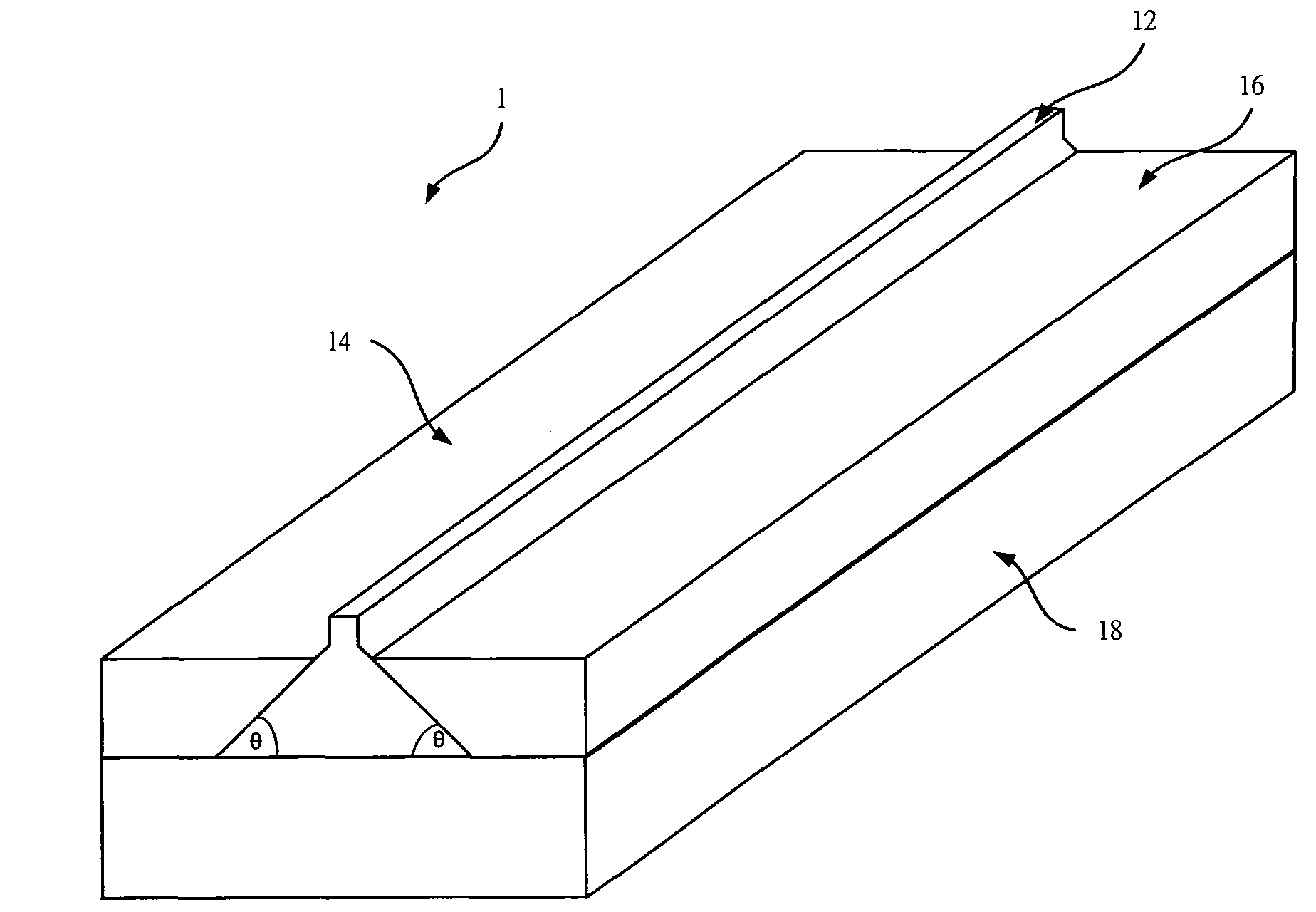

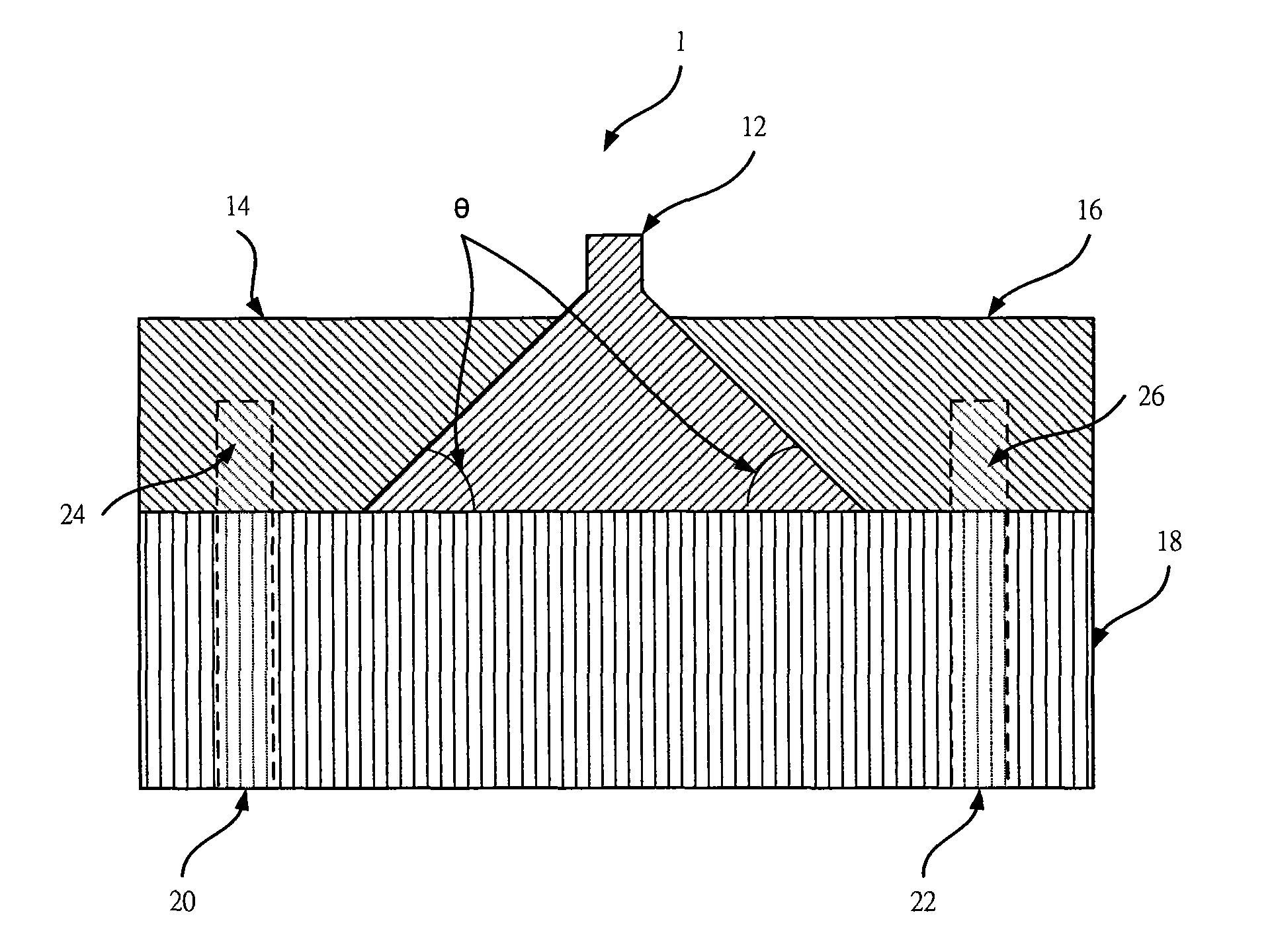

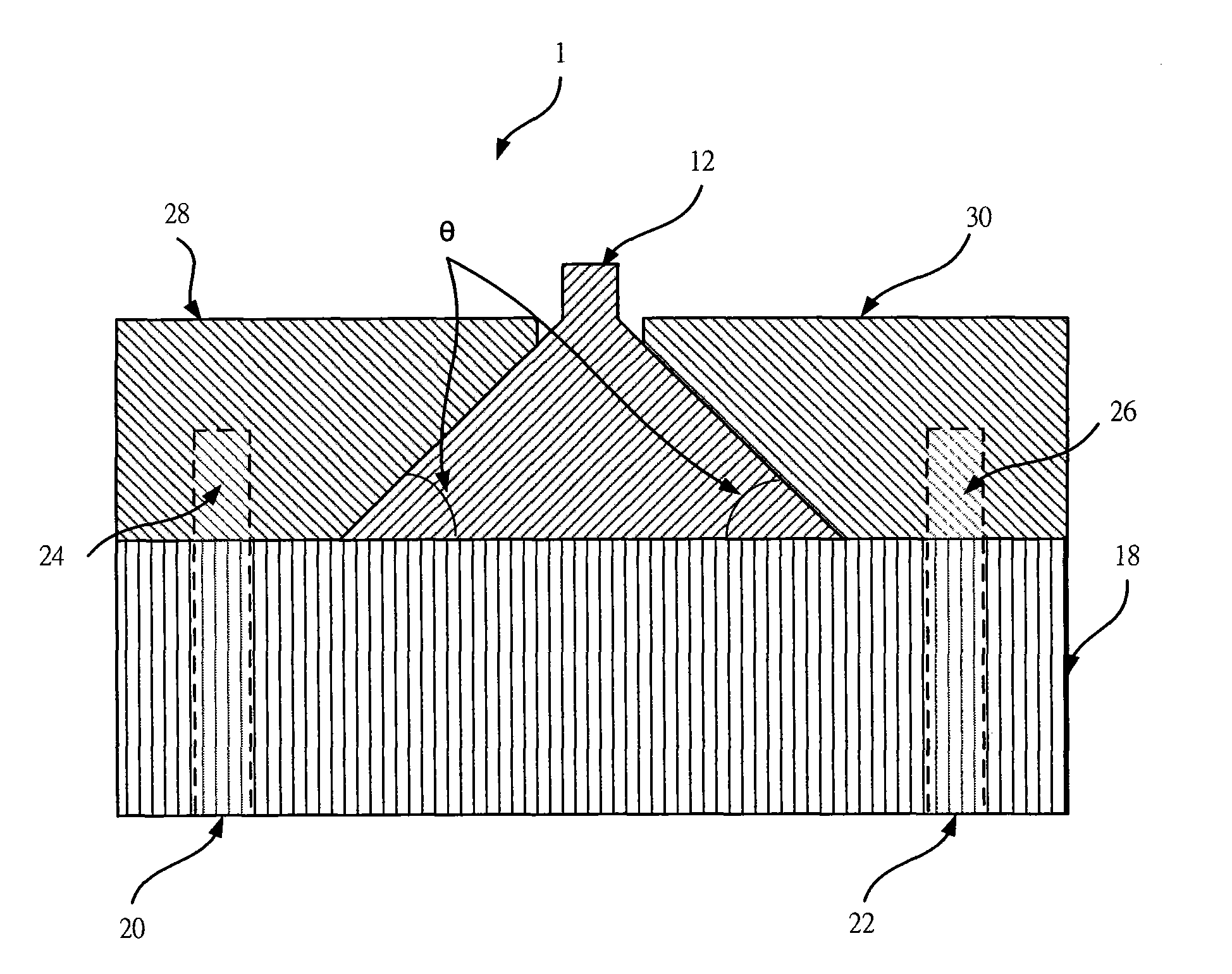

[0030] Please refer to figure 1 , The first example of the appearance of the detachable press device 1 of the present invention, the detachable press device includes: a detachable press head 12 and a fixing seat. Detachable indenter 12 from figure 1 It appears to be a bottom and a top structure. Wherein, the bottom has a trapezoidal strip cylinder, and the trapezoidal strip cylinder has two slopes and forms two acute angles θ, and the top is a rectangular strip cylinder connected with the short sides of a pair of parallel sides of the bottom trapezoid. become one piece. The fixed seat has a housing groove for accommodating the detachable pressure head 12. When the detachable pressure head 12 is installed in the fixed seat, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acute angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com