Multi-rope guide mine skip mechanism for coal lifting and unloading

The technology of skip and mine is applied in the field of multi-rope mine skip coal loading and unloading mechanism, which can solve problems such as inaccurate measurement and serious accidents, and achieve the effect of ensuring operation and avoiding rope breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

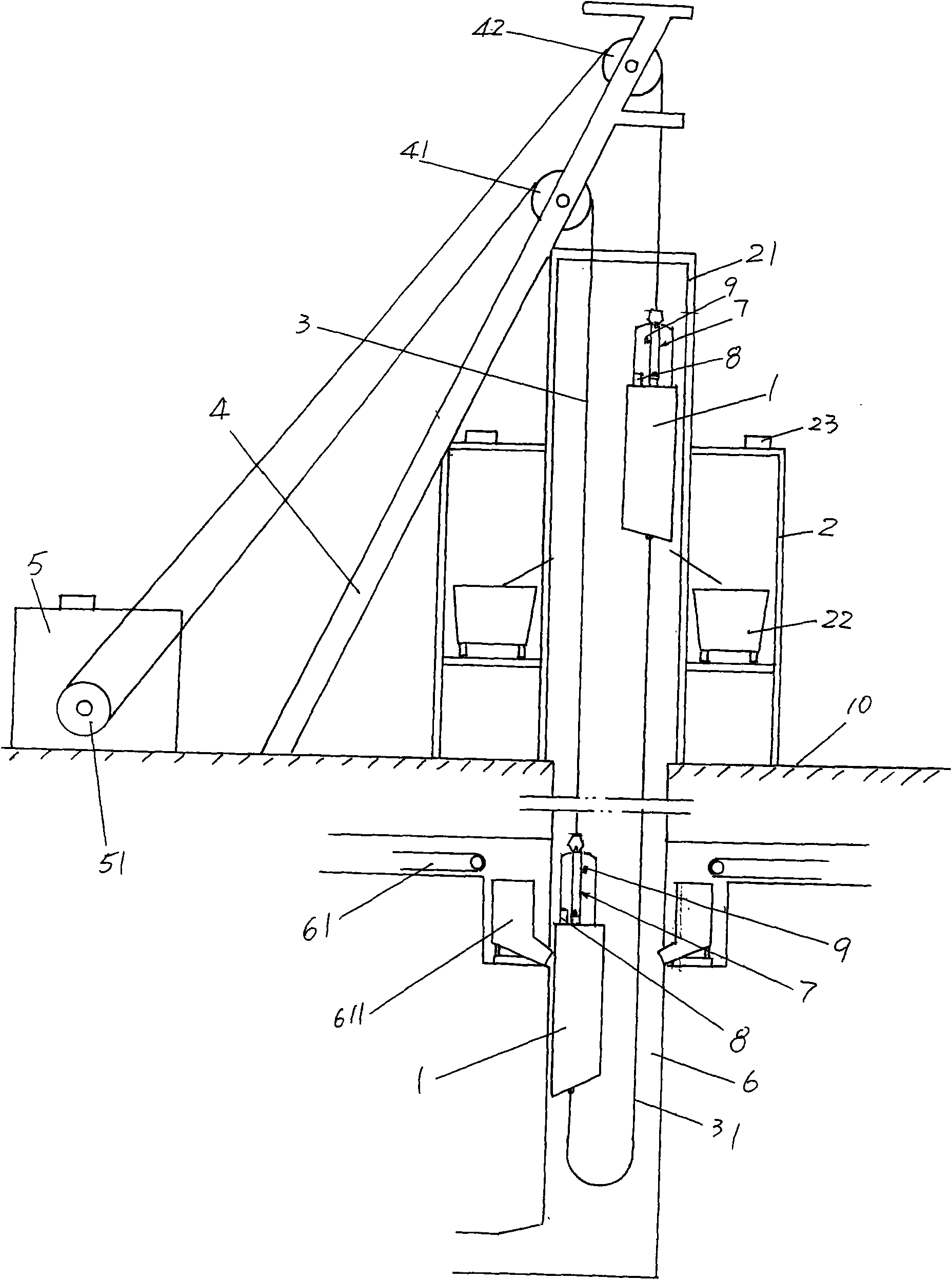

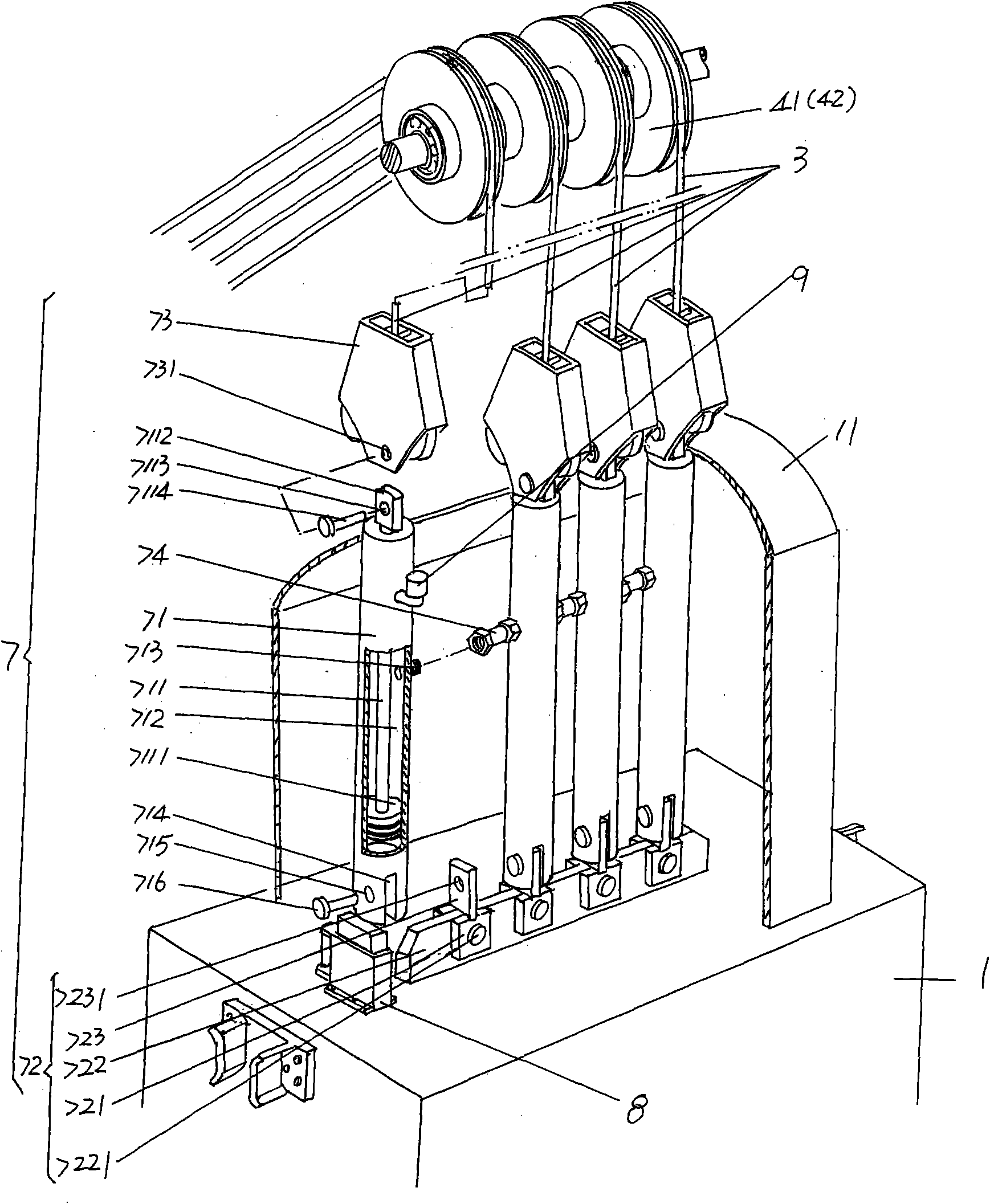

[0025] please see figure 1 with figure 2 , figure 1 It is the state that the multi-rope mine skip coal unloading mechanism of the present invention is arranged on the coal mine and seen from the side. The mechanism includes a group of traction ropes 3 and a pair of skips 1, and each A group of traction rope balancing devices 7 whose number is equal to the number of traction ropes 3 for balancing the force of a group of traction ropes 3 on the skip 1 is provided as a complete set of multi-rope mine skips for lifting coal and unloading coal in the present invention. institutions also include figure 1 Shown coal unloading platform 2, support 4 and winch device 5. In the present embodiment, the quantity of one group of traction ropes 3 is four, and the quantity of one group of traction rope balancing devices 7 is four ( figure 2 shown), one end of four traction ropes 3 is connected with four traction rope balancing devices 7 arranged on one of the skips 1 in a pair of ski...

Embodiment 2

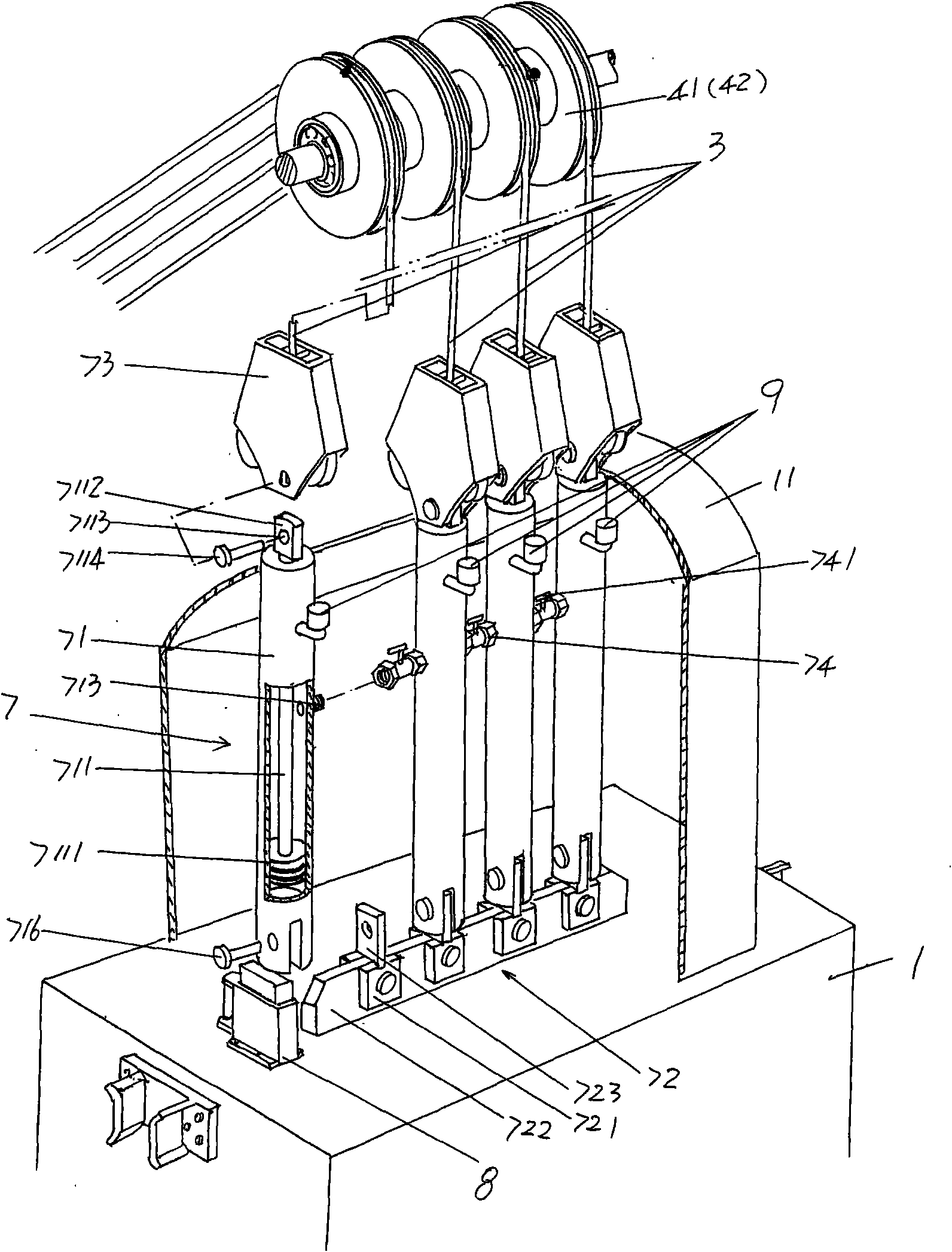

[0030] please see image 3 , each communication pipe 74 is provided with a cut-off valve 741 , the number of sensors 9 in this embodiment is equal to the number of traction rope balancing devices 7 , and they are all electrically connected to the signal transmitter 8 . Present embodiment can not carry out real-time adjustment to four traction ropes 3 at any time like embodiment 1, that is to say, only after opening the cut-off valve 741 on the pipeline of communication pipe 74, just can reflect the function of embodiment 1. However, under normal circumstances, the three shut-off valves 741 are closed, and the balance adjustment is performed by opening the shut-off valves 741 in the manner of regular inspection and maintenance. All the other are the same as the description to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com