Driller console, gas source conversion manifold and gas supply system

A driller's control and console technology, which is applied in earth-moving drilling, wellbore/well components, fluid pressure actuating devices, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

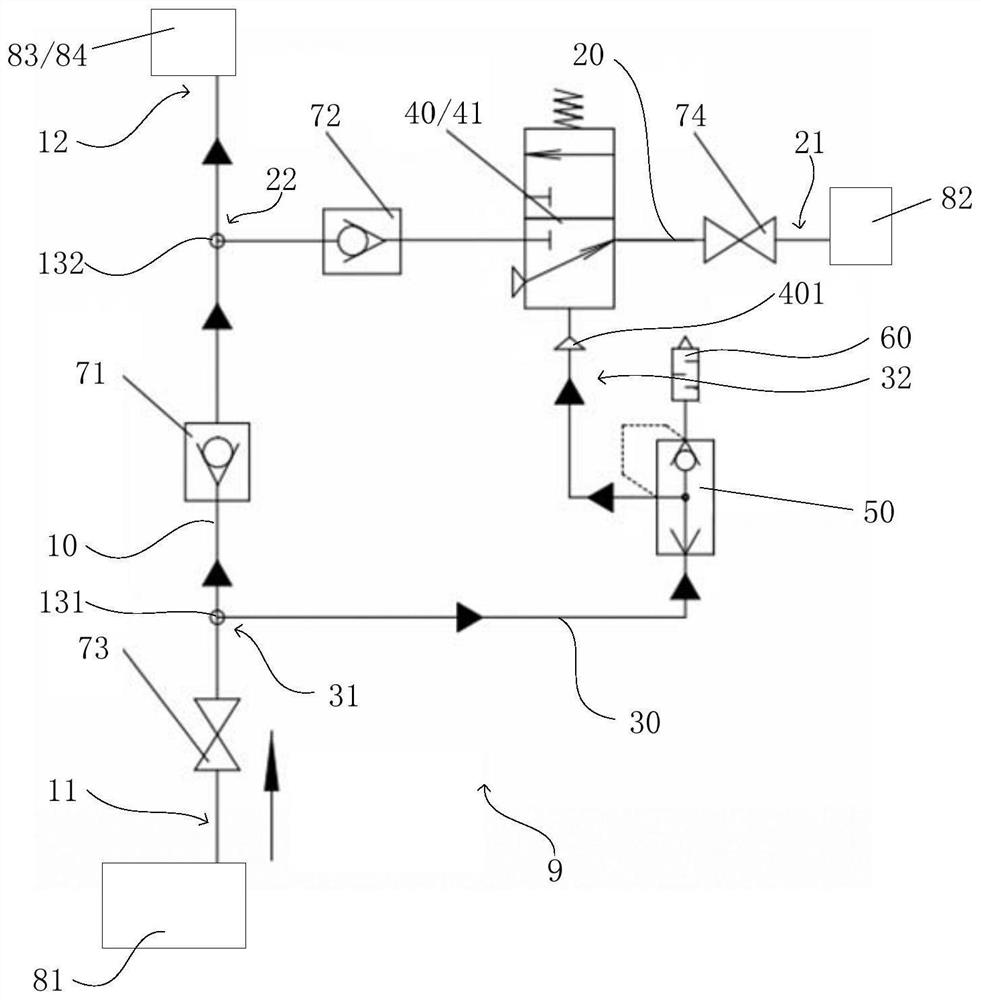

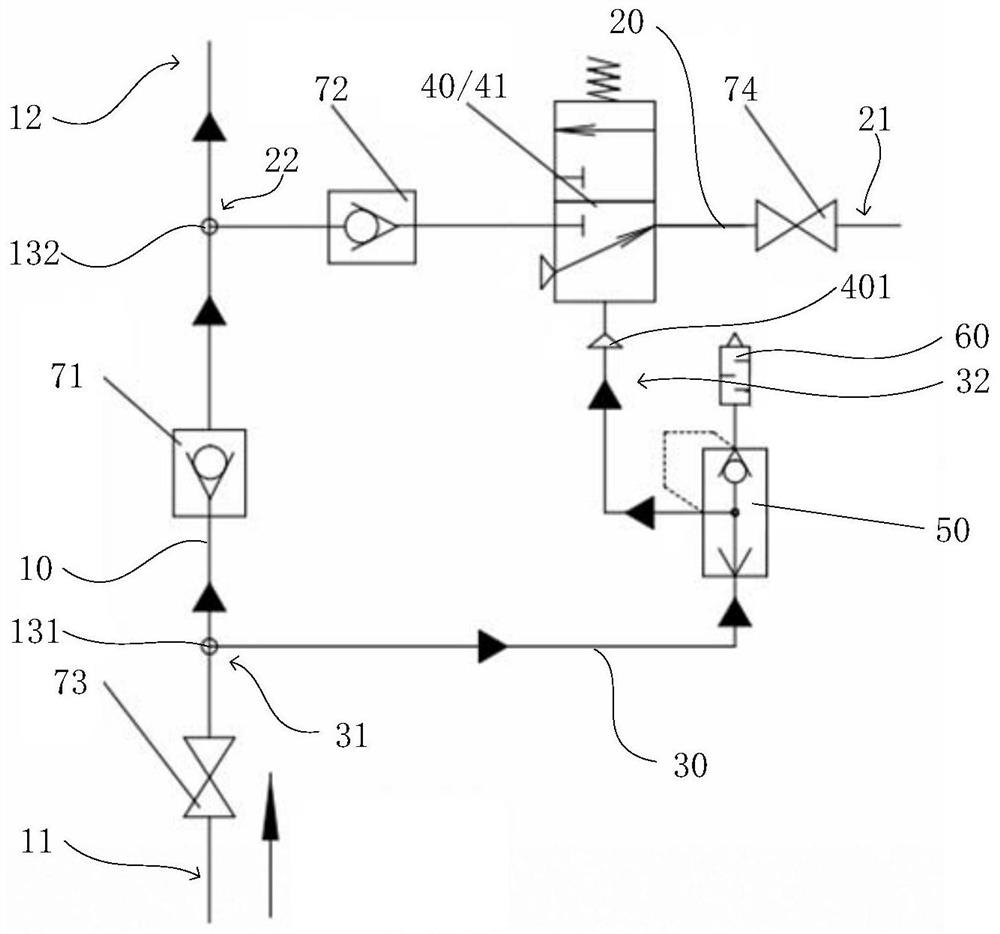

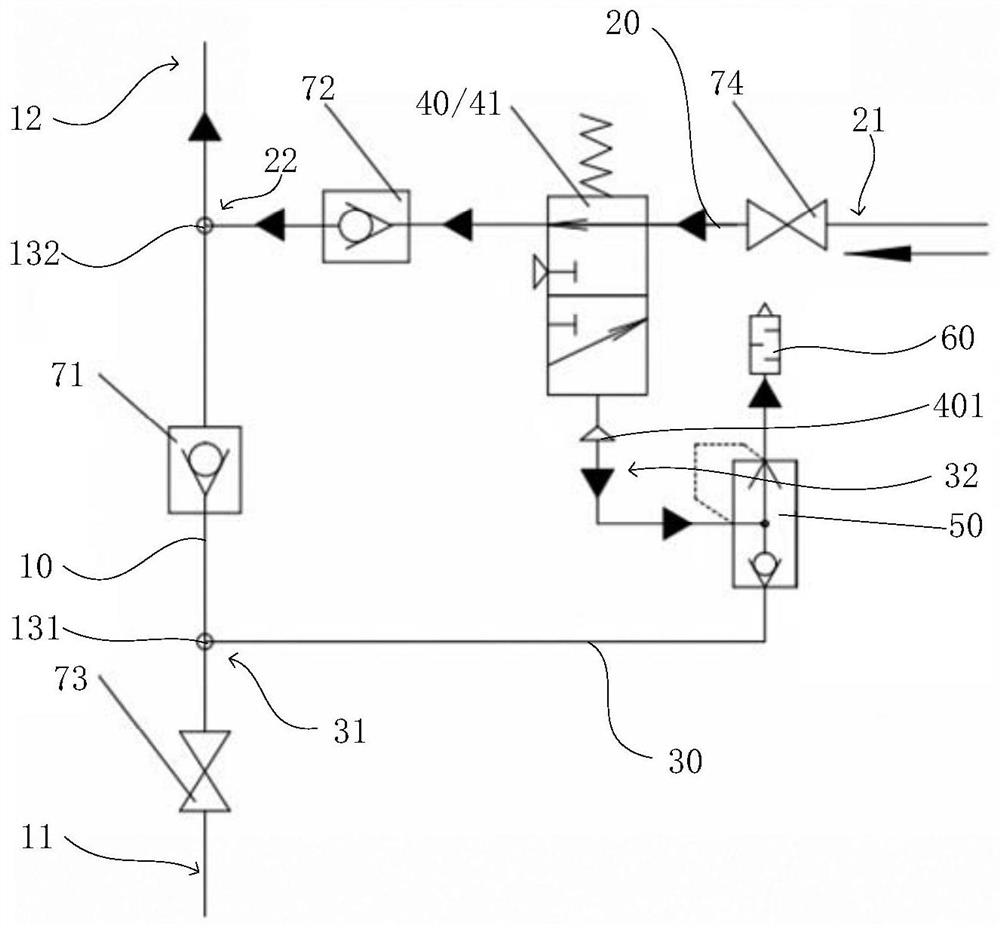

[0053] For air-operated BOP controls equipped with a driller's console. The invention provides a driller console, such as Figure 1 ~ Figure 3 As shown, the driller's console includes: a driller's control manifold 83, a first gas source 81, a second gas source 82 and a gas source conversion manifold 9, and the gas source conversion manifold 9 includes a first pipeline 10, a second gas source The second pipeline 20 and the third pipeline 30; the first gas source 81 is connected to the first end 11 of the first pipeline, and the second end 12 of the first pipeline is connected to the intake end of the driller's control manifold 83, The first gas source 81 can supply gas to the driller's control manifold 83 through the first pipeline 10; the second gas source 82 is connected with the first end 21 of the second pipeline, and the second end 22 of the second pipeline is connected with the driller. The air inlet end of the driller control manifold 83 is connected, and the second gas...

Embodiment 2

[0068] The invention provides a gas source conversion manifold, such as Figure 1 ~ Figure 3 As shown, the gas source conversion manifold includes: a first pipeline 10, a second pipeline 20 and a third pipeline 30, the first end 11 of the first pipeline is used to connect with the first gas source 81, the first The second end 12 of the pipeline is used to connect with the intake end of the air control manifold 84, and the first gas source 81 can supply air to the air control manifold 84 through the first pipeline 10; the first end of the second pipeline 21 is used to connect with the second gas source 82, the second end 22 of the second pipeline is used to connect with the intake end of the air control manifold 84, and the second gas source 82 can be the air control tube through the second pipeline 20 Sink 84 supplies air; the second pipeline 20 is provided with an air control reversing valve 40 for controlling the on-off of the second pipeline 20, when the compressed air ente...

Embodiment 3

[0078] The present invention provides a gas supply system, including: a first gas source 81, a second gas source 82, and the above-mentioned gas source conversion manifold, the first end 11 of the first pipeline, and the first end 11 of the third pipeline. One end 31 is connected to the first gas source 81 , and the first end 21 of the second pipeline is connected to the second gas source 82 . The air supply system is not limited to supply air to the driller's control manifold 83, and the air supply system can also be applied to other systems that require air supply. In this gas supply system, the first gas source 81 can be used as the main gas source, the second gas source 82 can be used as the backup gas source, and the second pipeline 20 connected to the second gas source 82 can No automatic disconnection and connection, when the first gas source 81 is in normal operation, the gas can be supplied by the first gas source 81; when the first gas source 81 fails, it will be aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com