Heavy-load anti-explosion full-steering vehicle and control method

A full-steering, frame-based technology, applied to steering mechanisms, power steering mechanisms, fluid steering mechanisms, etc., can solve problems such as small loads and inflexible steering, reduce ground pressure, and ensure installation, commissioning, and operation , good bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

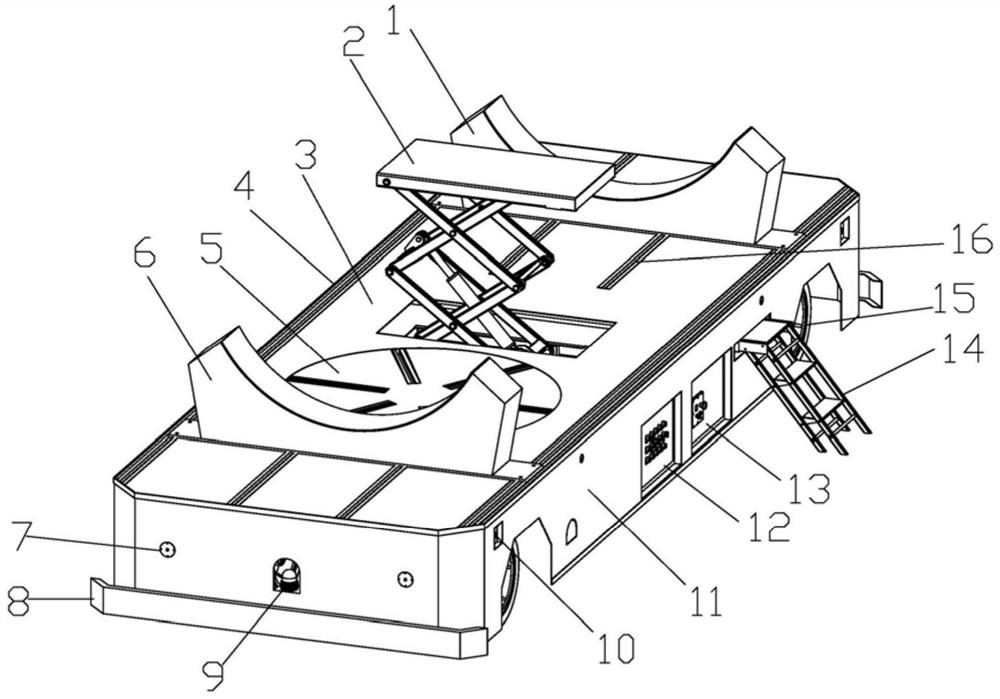

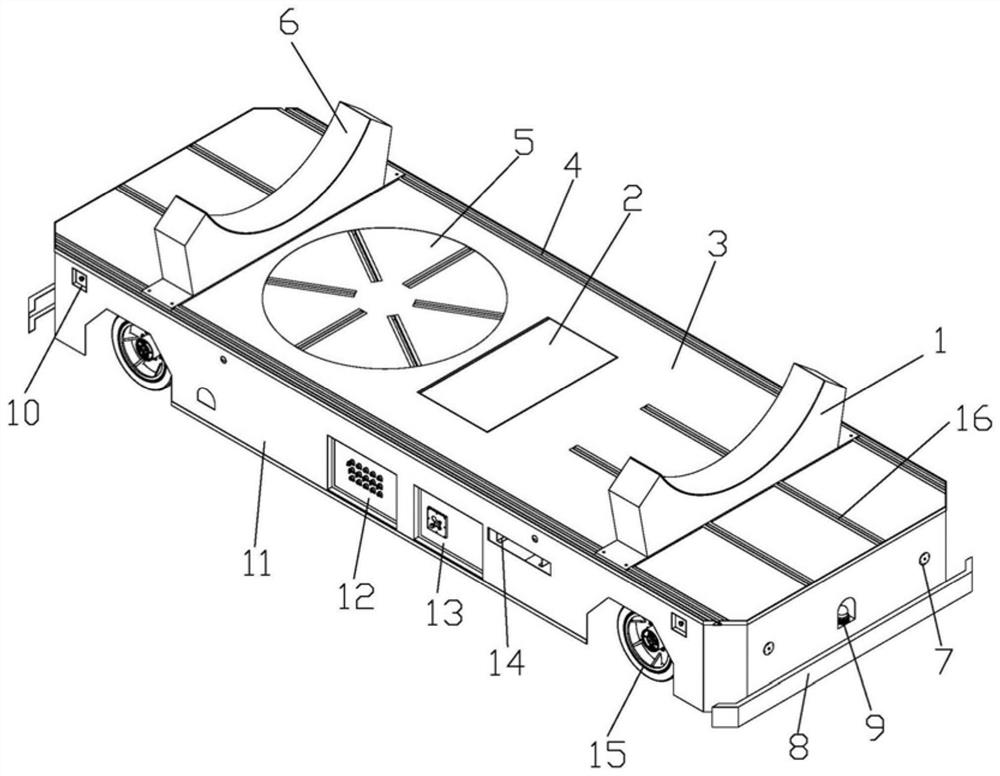

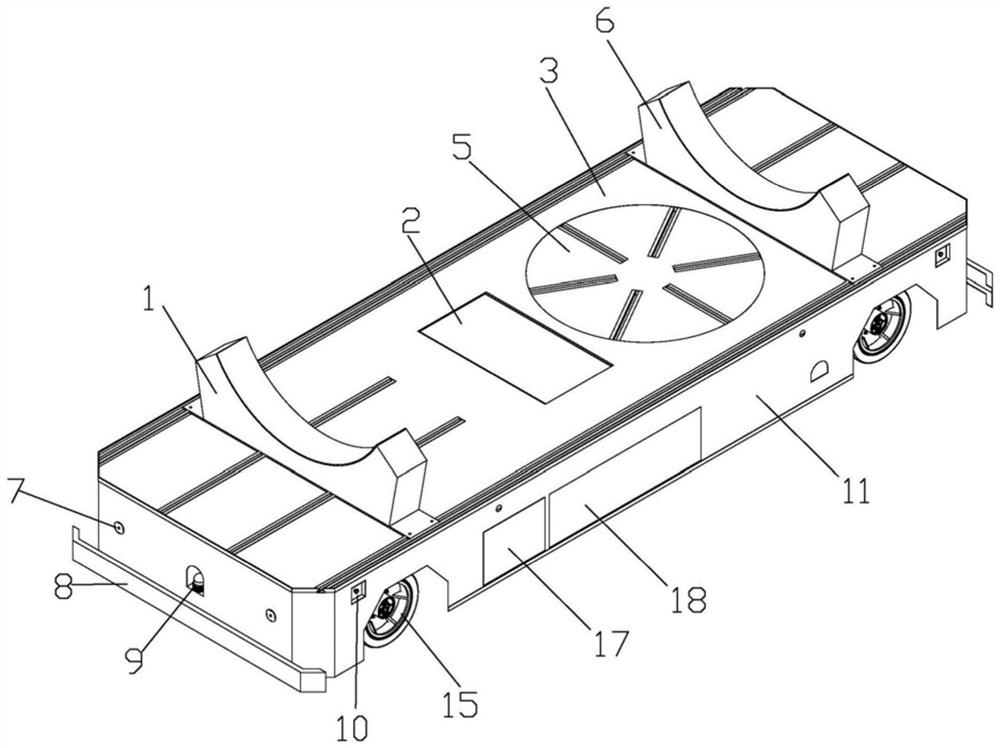

[0045] Such as Figures 1 to 12 As shown, the present embodiment provides a heavy-duty explosion-proof omni-steering vehicle, including a vehicle frame 4, a support bracket 40, a lifting table 2, a turntable assembly 5 and a wheel assembly 15; the two ends of the top of the vehicle frame 4 are respectively There is one support bracket 40, the top of the vehicle frame 4 is located between the two support brackets 40, and the lifting table 2 and the turntable assembly 5 are provided; the bottom sides of the vehicle frame 4 Multiple wheel assemblies 15 are provided.

[0046] A floor 3 is arranged on the top surface of the vehicle frame 4 , and a hoarding plate 11 is arranged around the vehicle frame 4 .

[0047] A set of sliding slots 16 are respectively provided at both ends of the top of the vehicle frame 4 , and the support bracket 40 is slidably disposed on the sliding slots 16 . Concretely, each set of chute 16 includes four chute 16 evenly arranged from one side of the ve...

Embodiment 2

[0057] Such as Figures 13 to 18 As shown, this embodiment provides a control method for the heavy-duty explosion-proof omni-steer vehicle in Embodiment 1, including the following modes:

[0058] 1. Straight mode; such as Figure 13 As shown, the vehicle runs normally without turning; the included angle of the wheel assembly 15 along the vehicle axis is zero;

[0059] Second, in-situ steering mode; Figure 14 As shown, each wheel assembly 15 forms a certain angle with the vehicle axis, each wheel assembly 15 is not parallel, and the vehicle rotates in situ around its own center;

[0060] Three, oblique mode; such as Figure 15 and 16 As shown, each wheel assembly 15 rotates at the same angle around its own axis, and the angle is not equal to 0 degrees or 90 degrees; the driving direction of the vehicle forms an angle with the axis of the vehicle body, and the angle is the same as the rotation angle of the wheel assembly 15;

[0061] Fourth, the eight-character pattern; su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com