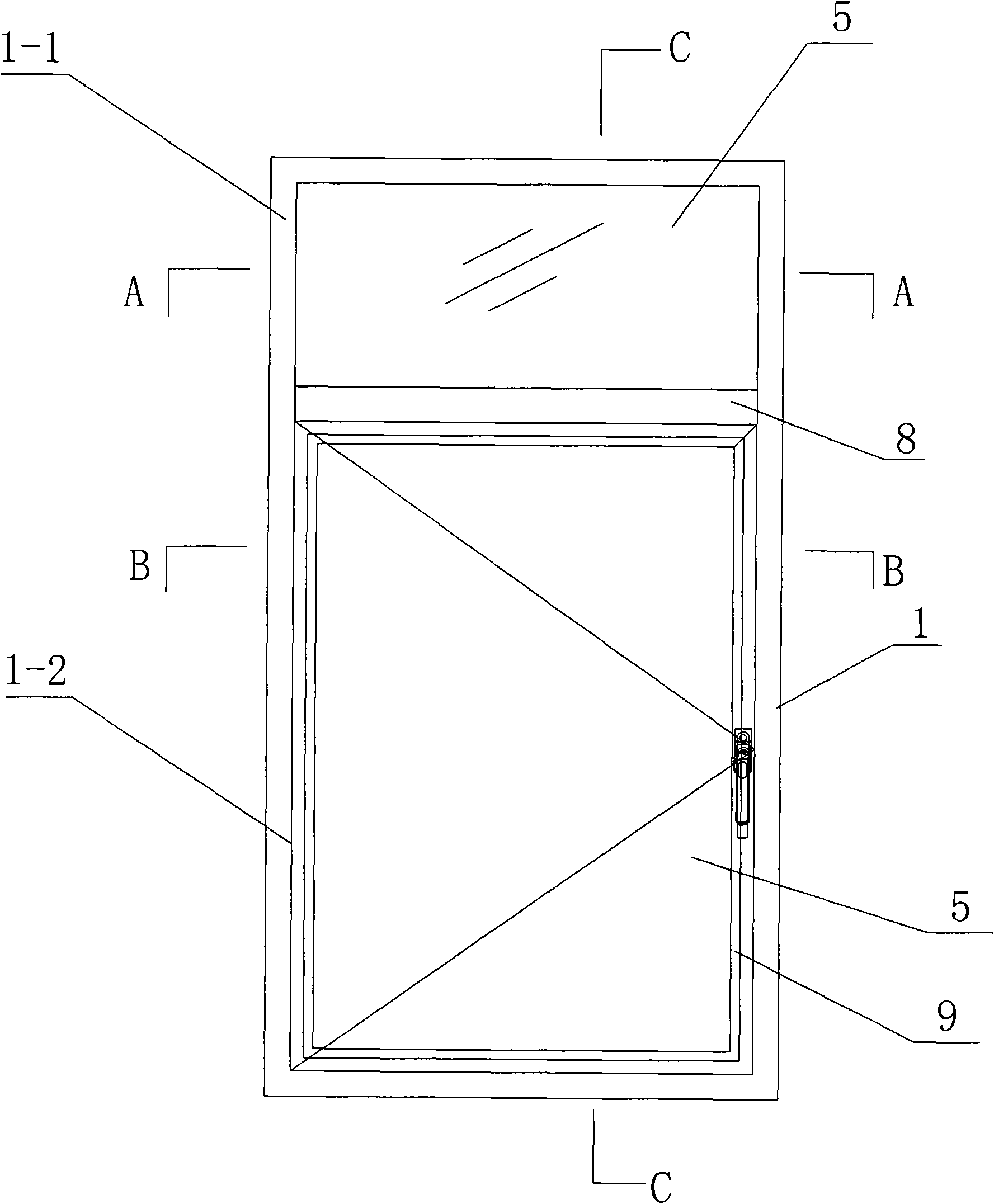

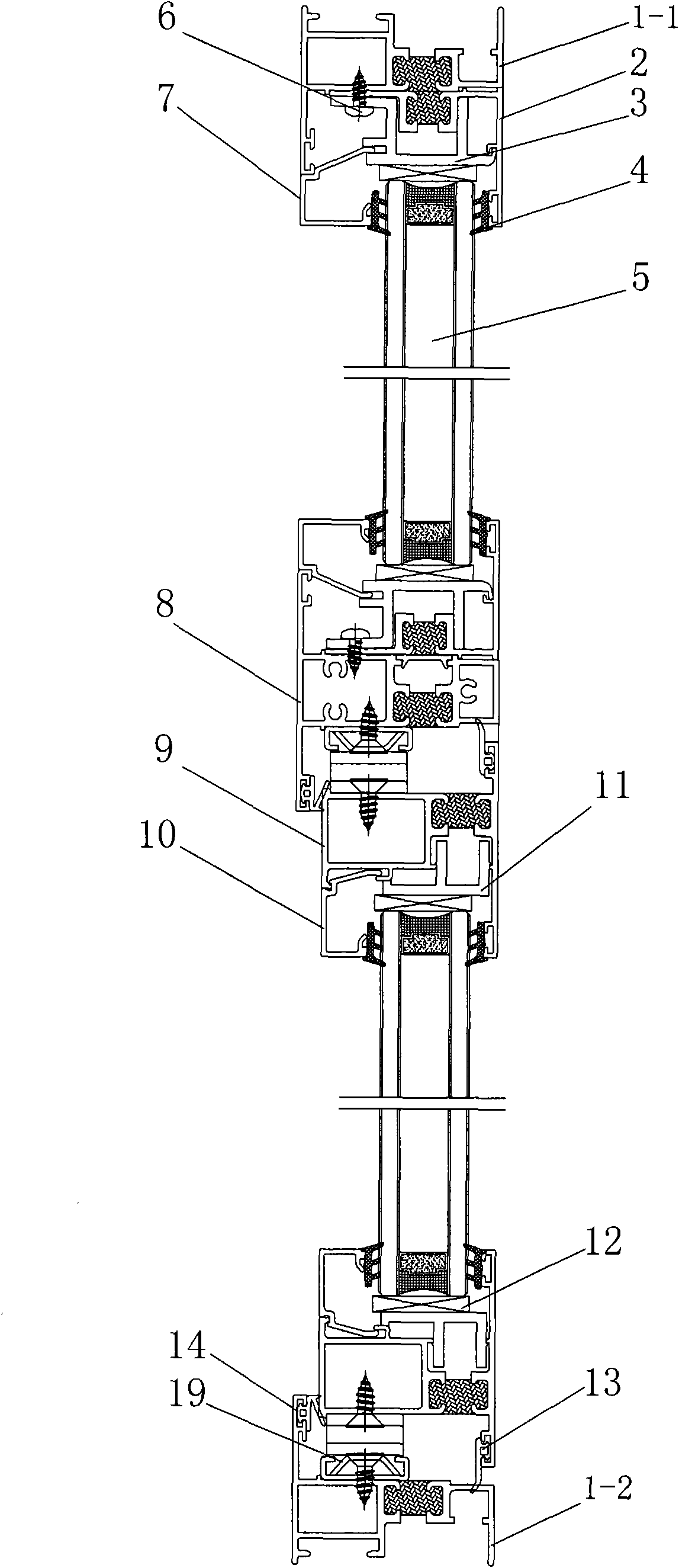

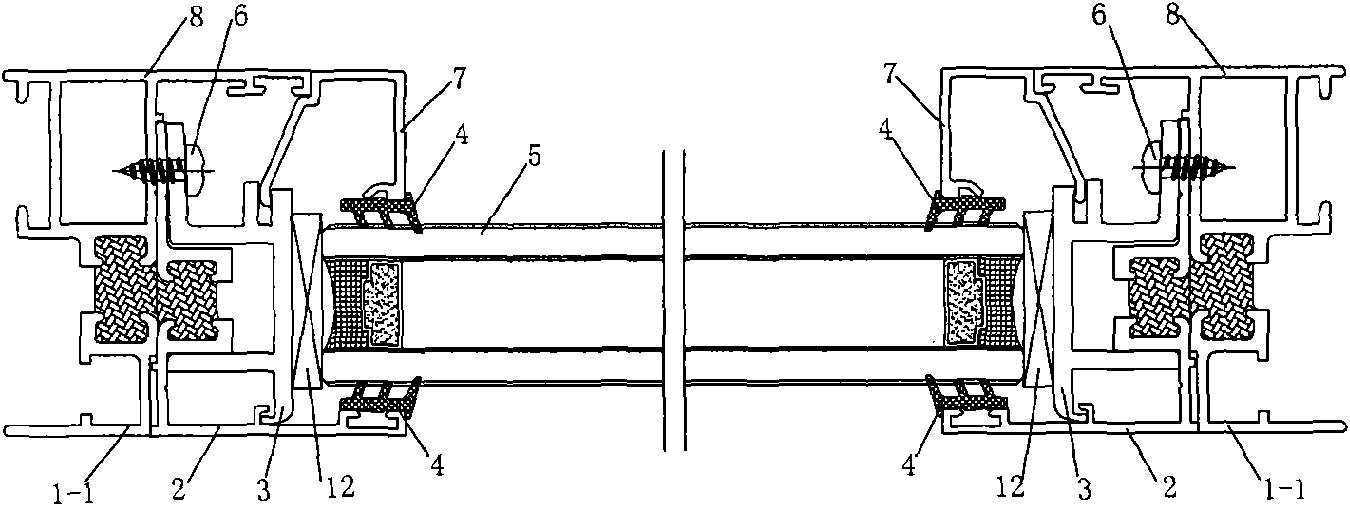

Energy-saving casement window

A technology for casement windows and opening frames, applied in door/window accessories, parallel glass structures, folding panels, etc., can solve the problem of affecting the use effect of casement windows, unsatisfactory thermal insulation and energy saving effect, and shortening the service life of casement windows. and other problems, to achieve the effect of energy-saving decoration effect, beautiful appearance, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0034] The biggest difference between embodiment 2 and embodiment 1 is that the fixed frame is arranged at the lower part of the open frame, and the top edge of the fixed frame is connected with the bottom edge of the open frame through a center pole.

Embodiment 3

[0036] The biggest difference between embodiment 3 and embodiment 1 is that the fixed frame is arranged on the side of the open frame, and the side of the fixed frame is connected with the corresponding side of the open frame through the middle pole, and the fixed frame is fixed The height of the frame is consistent with the height of the open frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com