Patents

Literature

35results about How to "Comfortable appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

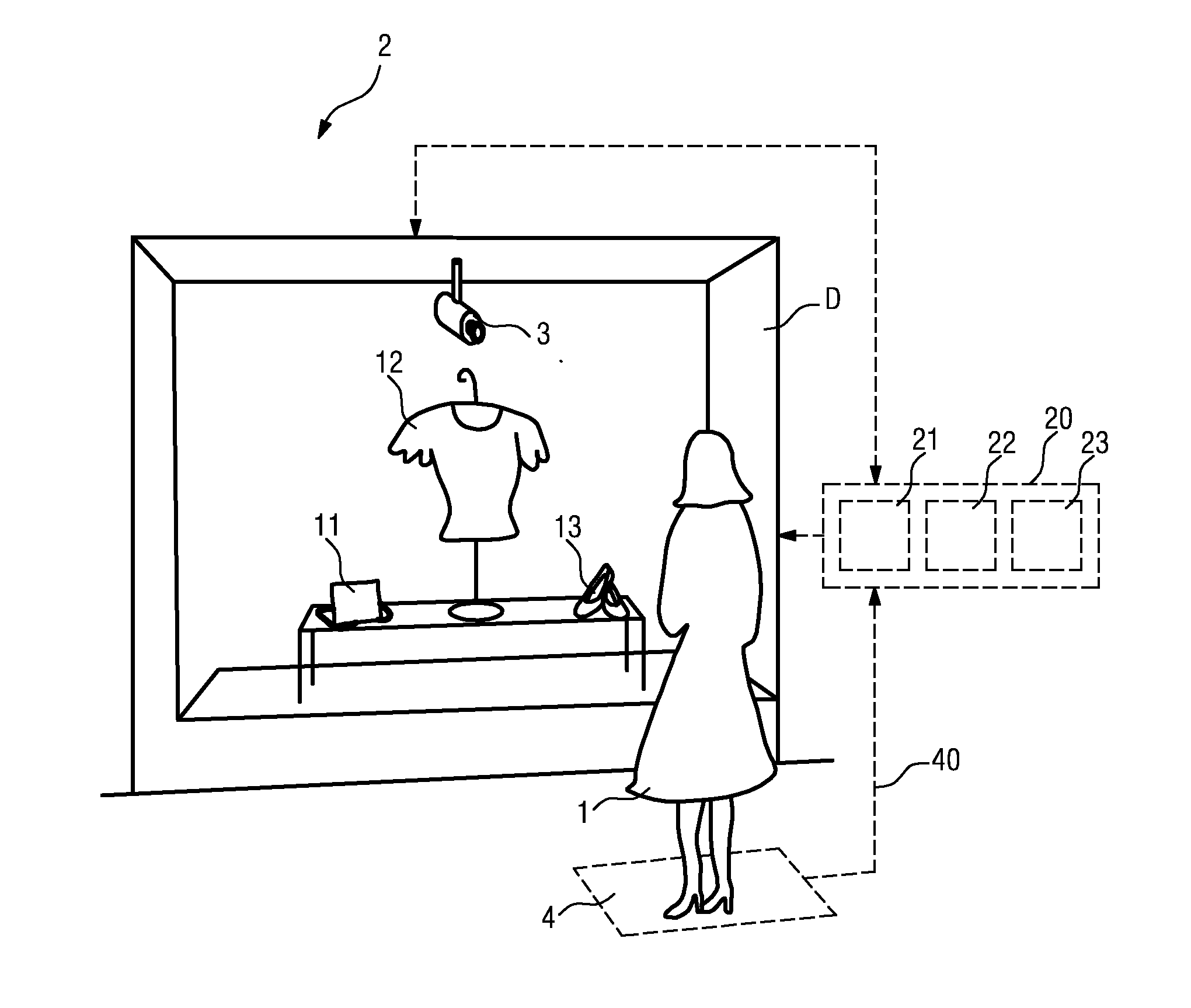

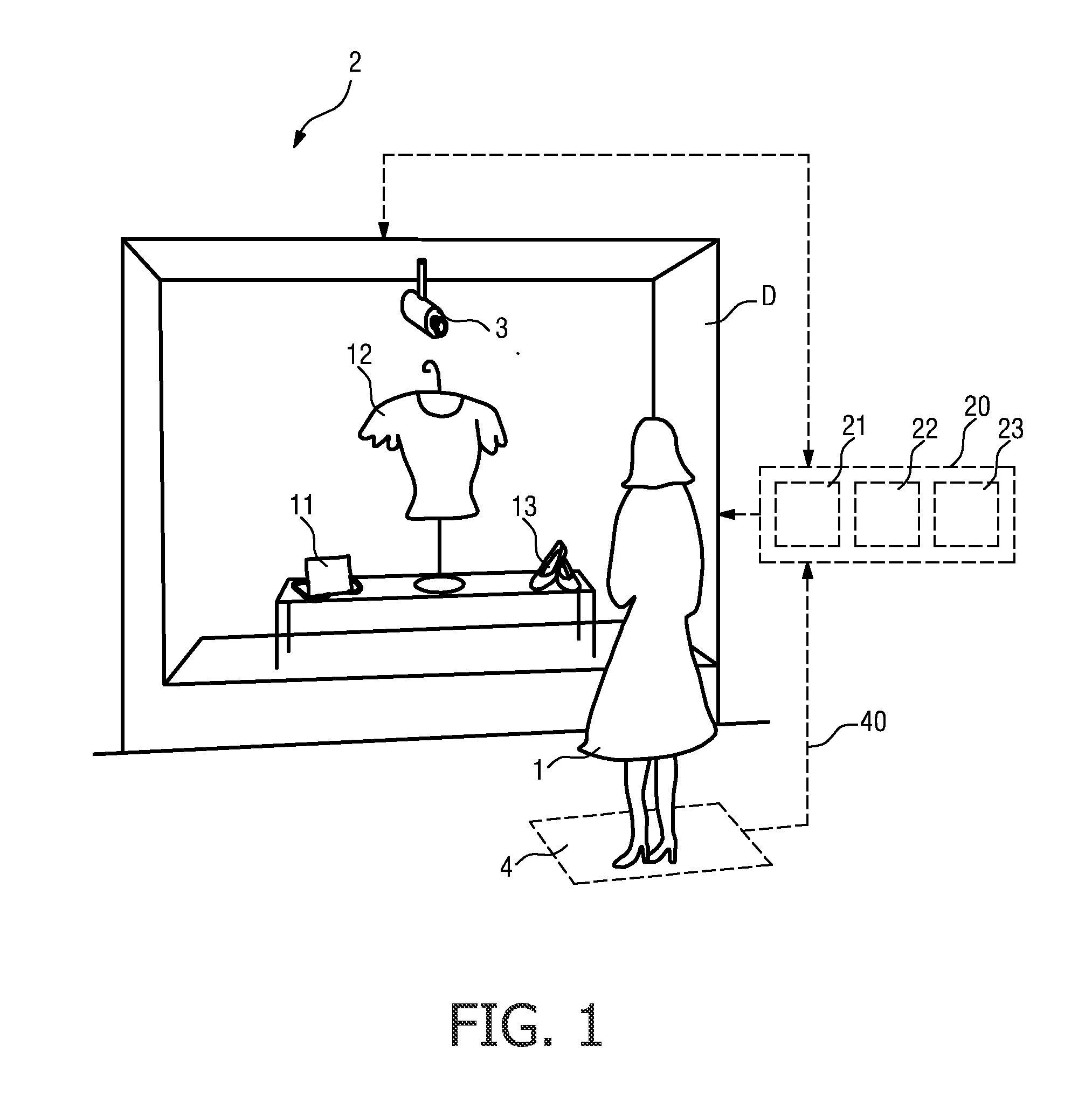

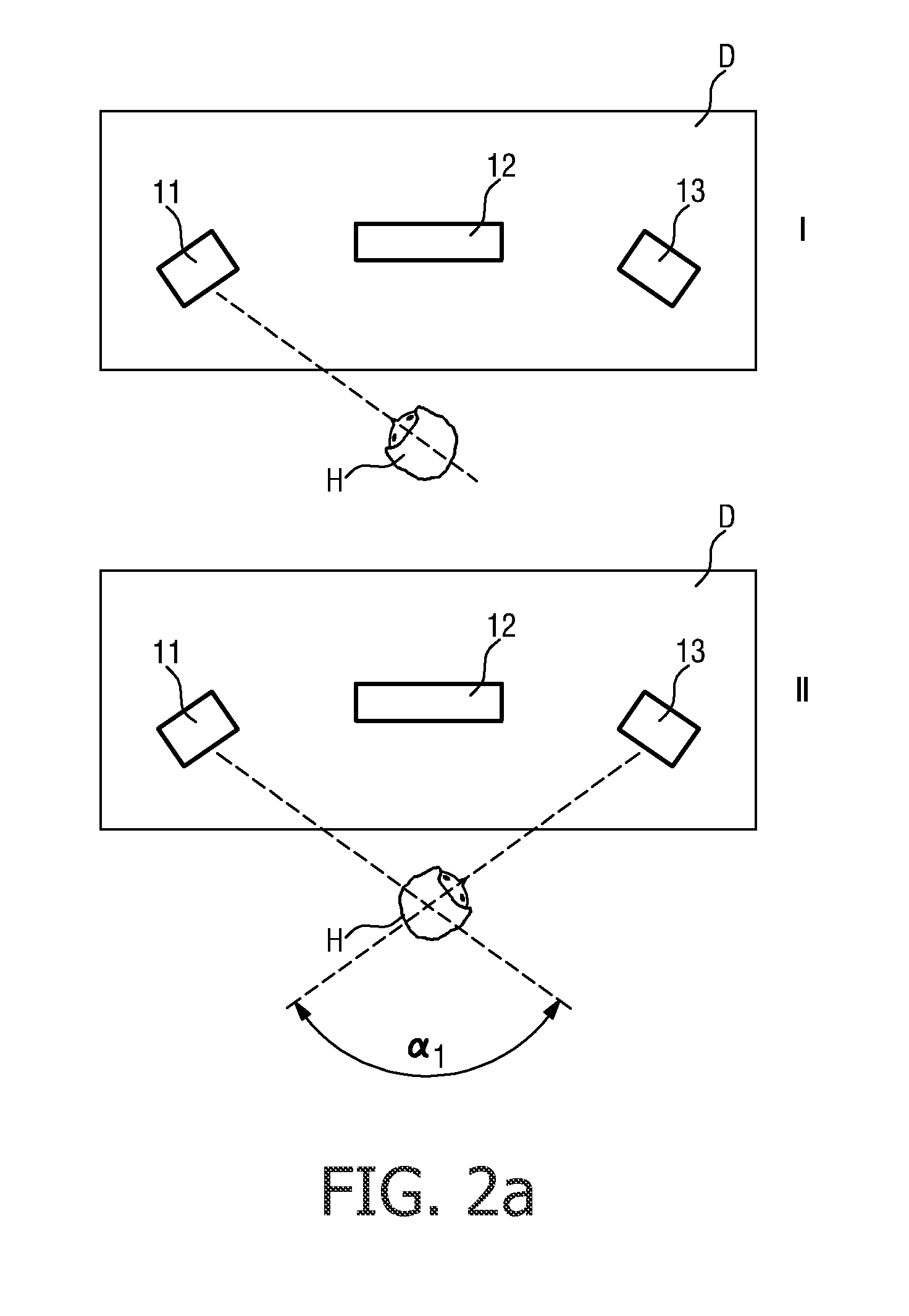

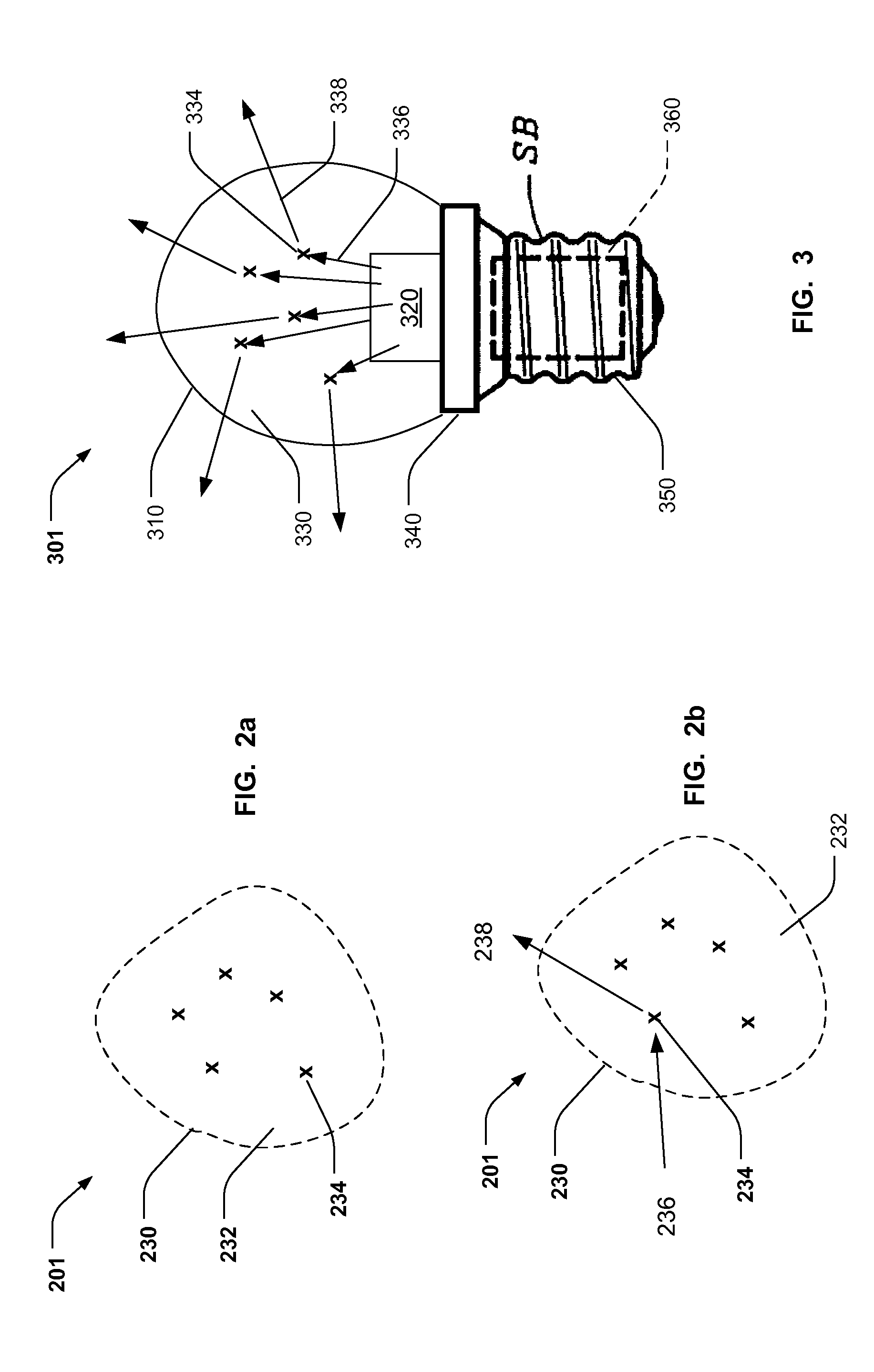

Method of and system for determining a head-motion/gaze relationship for a user, and an interactive display system

InactiveUS20110128223A1Accurate CalibrationComfortable appearanceCathode-ray tube indicatorsInput/output processes for data processingHead movementsOrientation measurement

The invention describes a method of determining a head-motion / gaze relationship for a user (1), which method comprises the steps of allocating at least one first target (T1) and at least one second target (T2) in a display area (D); attracting the user's gaze towards a first target (T1) and observing the user's head (H) to obtain a first head orientation measurement value (M1). The method further comprises the steps of subsequently attracting the user's gaze towards a second target (T2) and observing the user's head (H) to obtain a second head orientation measurement value (M2); and analysing the head orientation measurement values (M1, M2) to obtain a head-motion / gaze relationship (R) for that user (1). The invention further describes an interactive display system (2), and a method of performing a gaze-based interaction between a user (1) and an interactive display system (2).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

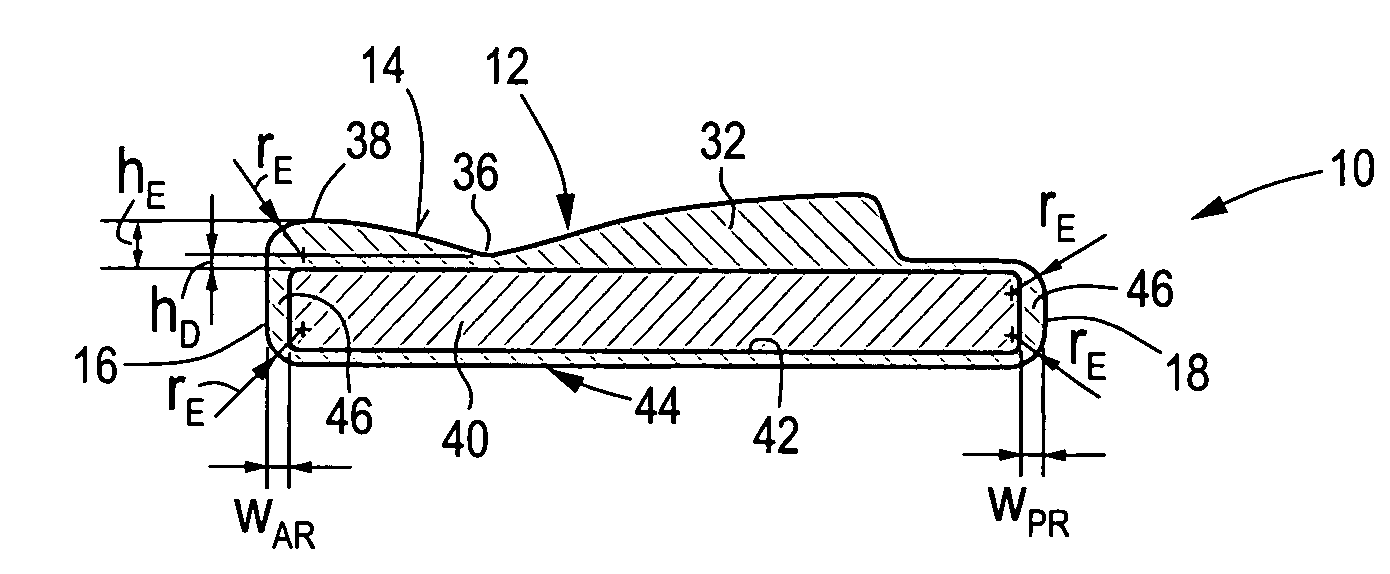

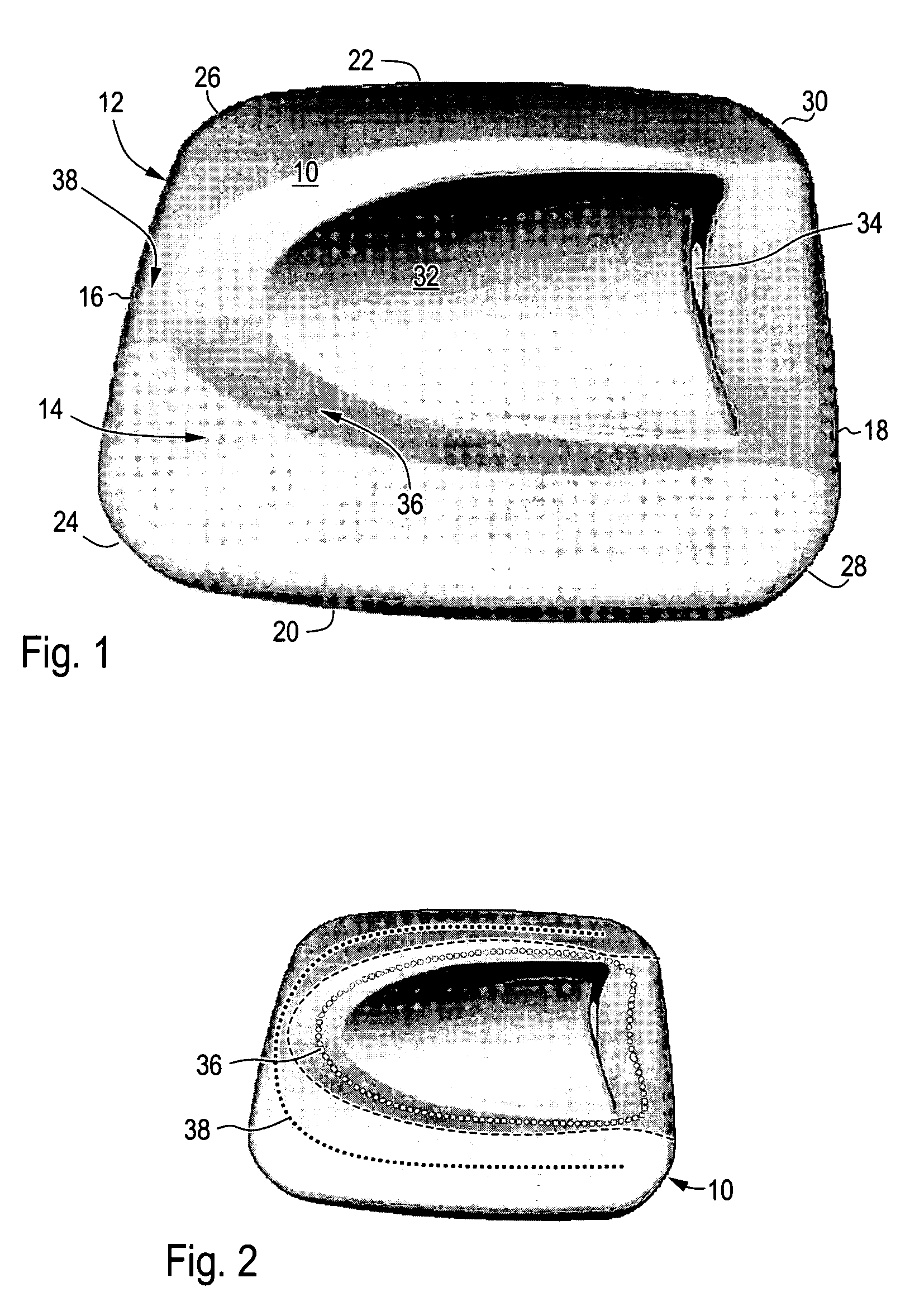

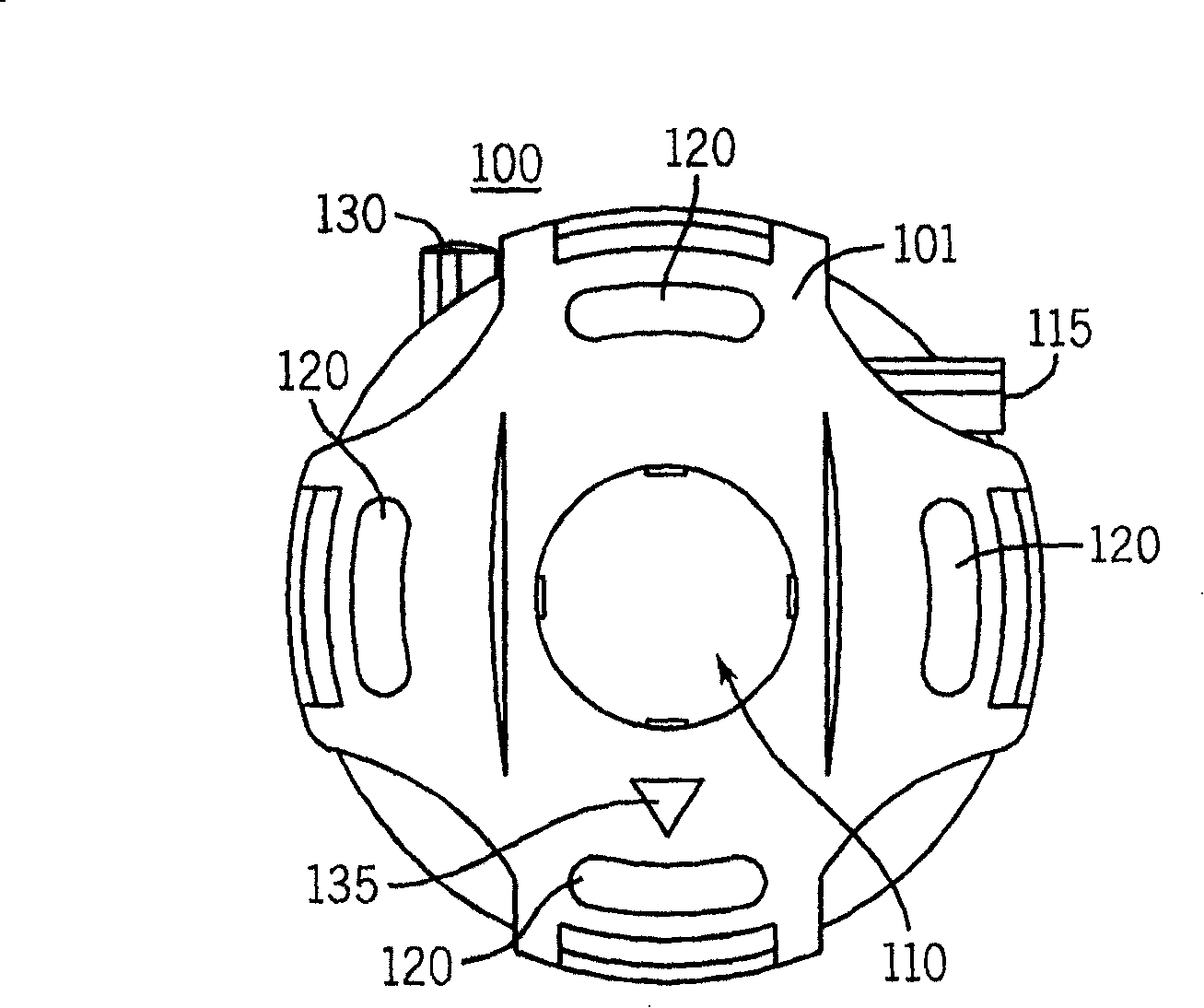

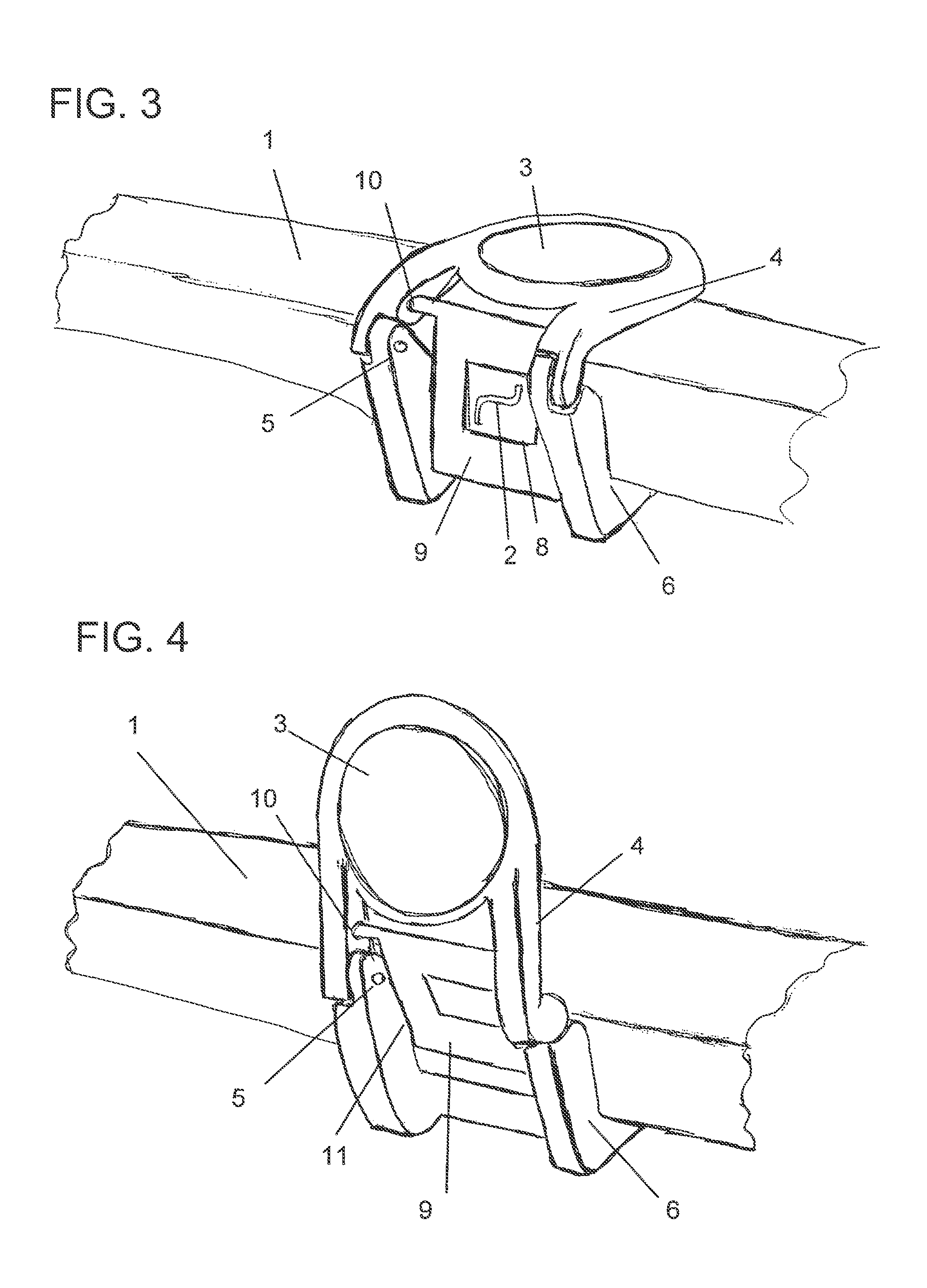

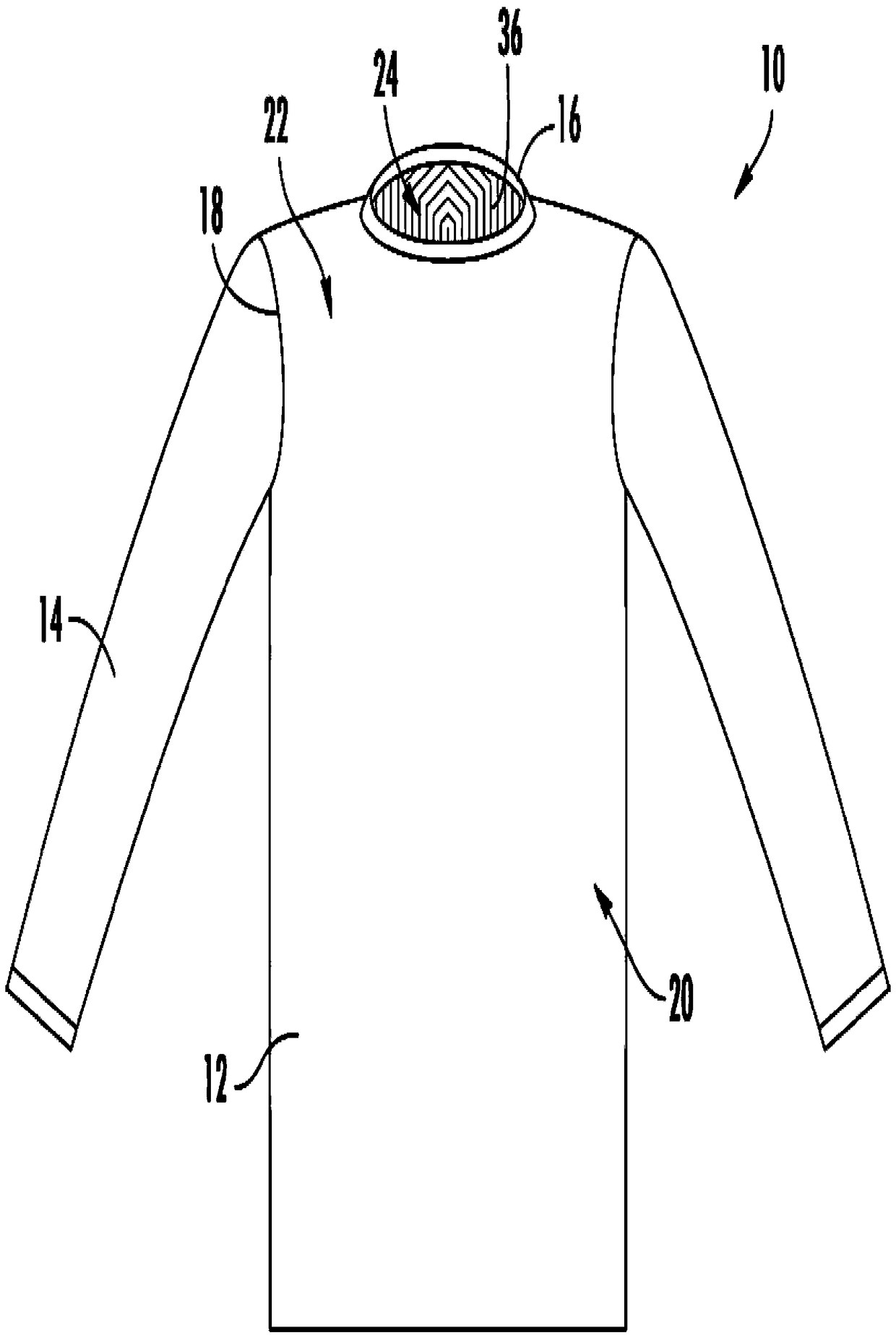

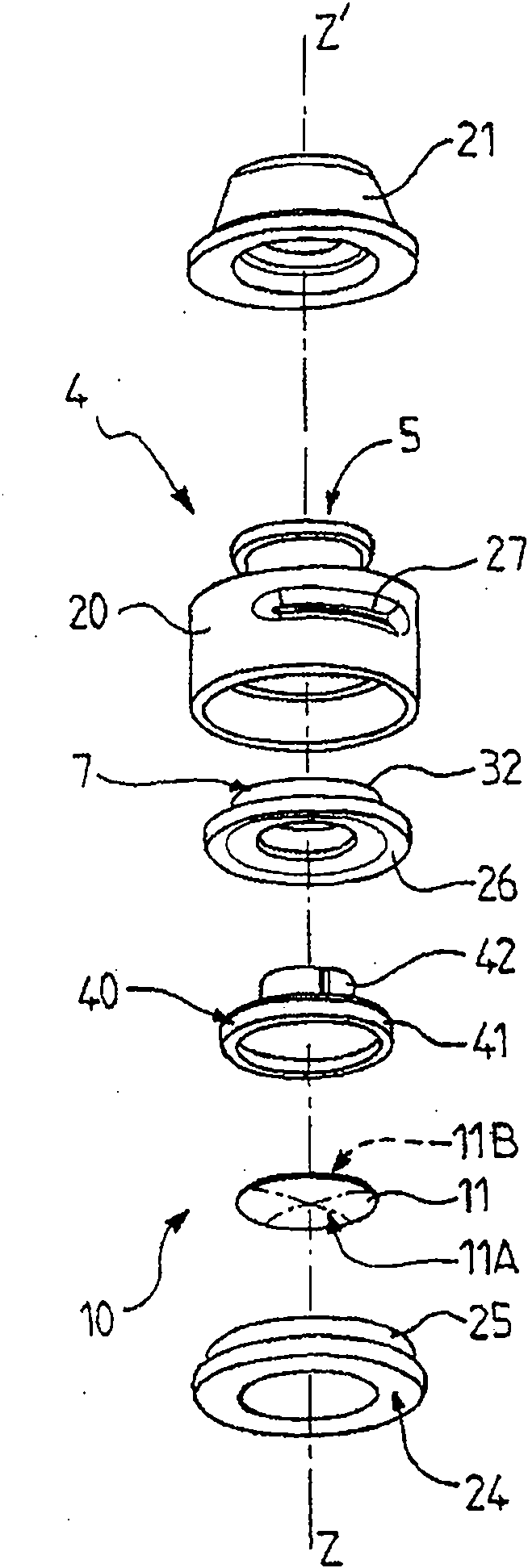

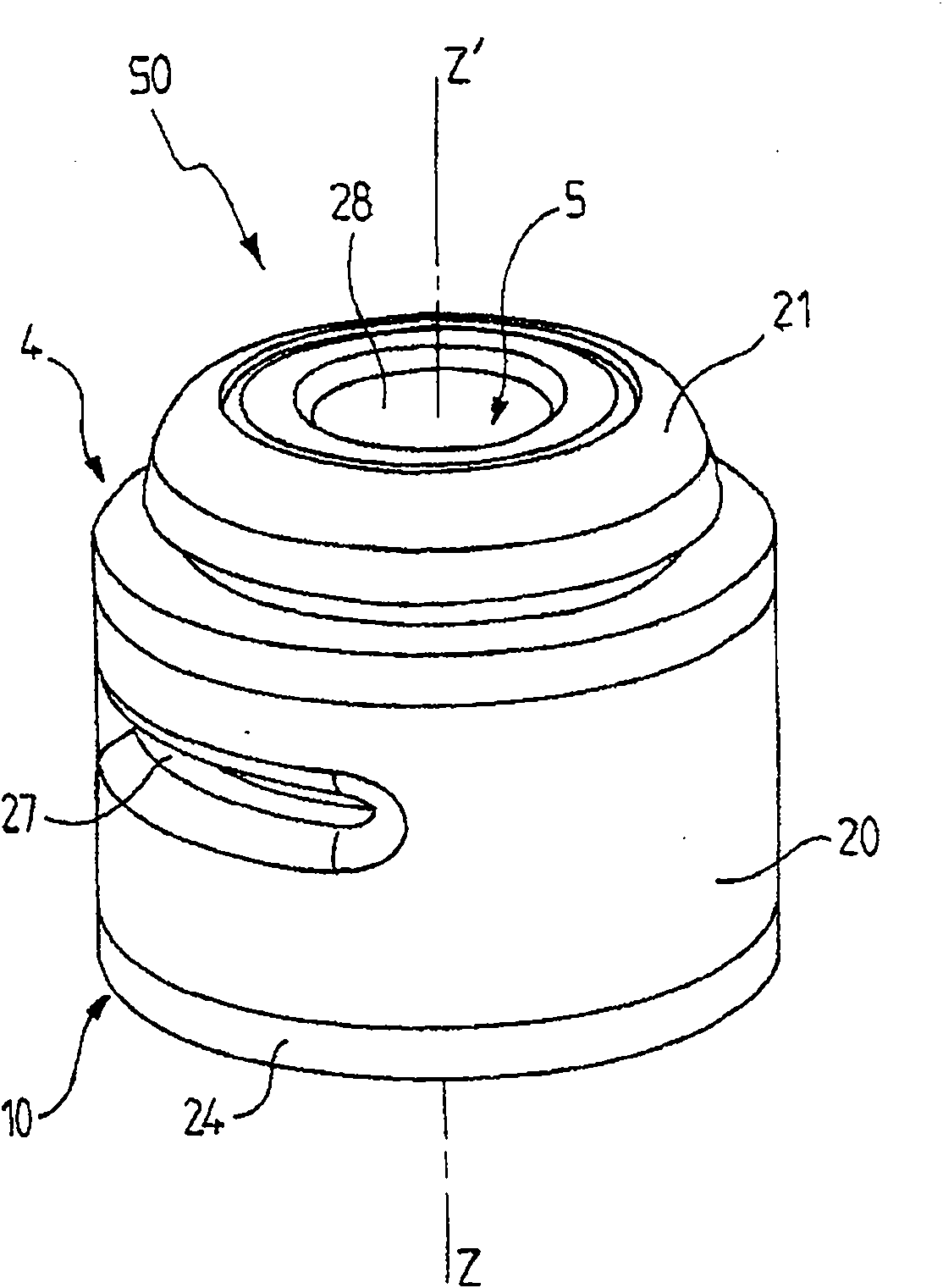

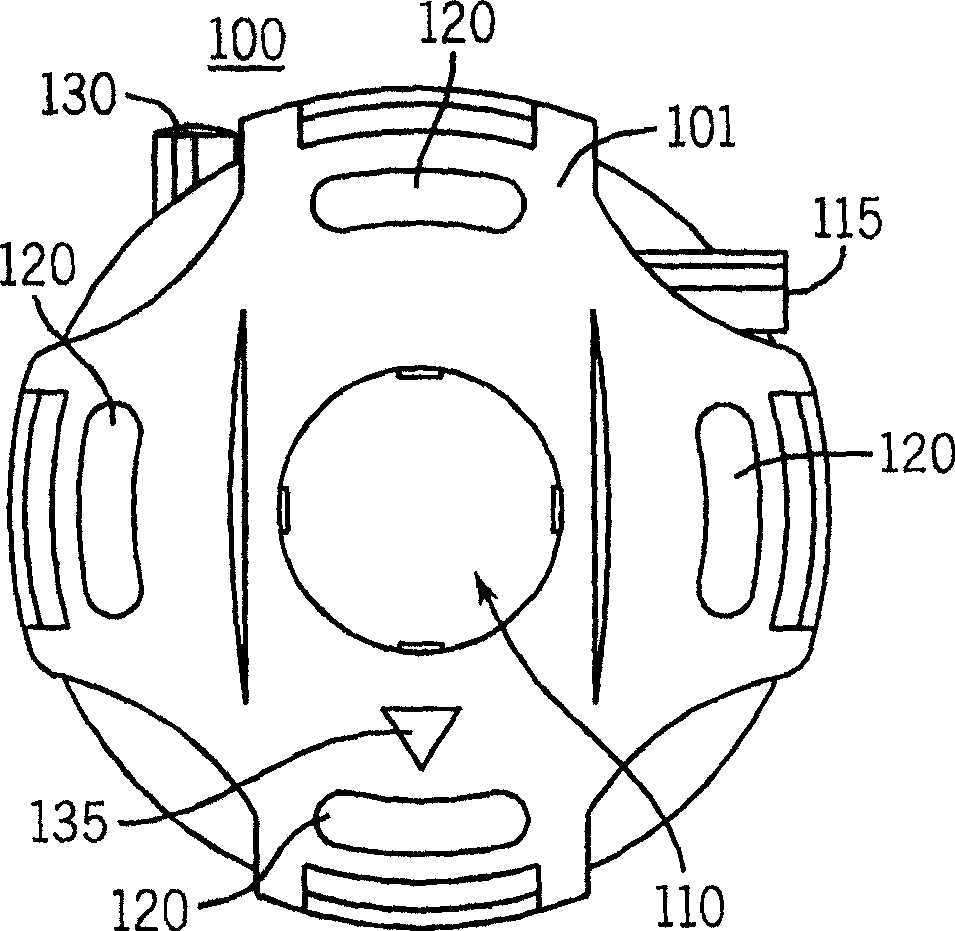

Image sensor for dental intraoral radiography

InactiveUS7281847B2Good patient cooperationQuality improvementTelevision system detailsX-ray/infra-red processesX ray imageImage sensor

An image sensor (10) for dental intraoral radiography comprises a housing (12), an image receptor (40) and a cable connection dome (32) arranged on a back side (14) of the housing (12). The back side (14) of the housing (12) has a depression (36) at least in the region between the cable connection dome (32) and an anterior side (16) of the housing (12), wherein the depression (36) falls short of reaching the anterior side (16) of the housing (12) such that an elevated region (38) is formed between the depression (36) and at least the anterior side (16) of the housing (12). A positioning device (50) is adapted for positioning an image sensor (10) according to the present invention in the mouth of a patient. The present invention provides an intraoral sensor that enables good patient cooperation, thus making it possible to take high quality dental x-ray images.

Owner:GENDEX +1

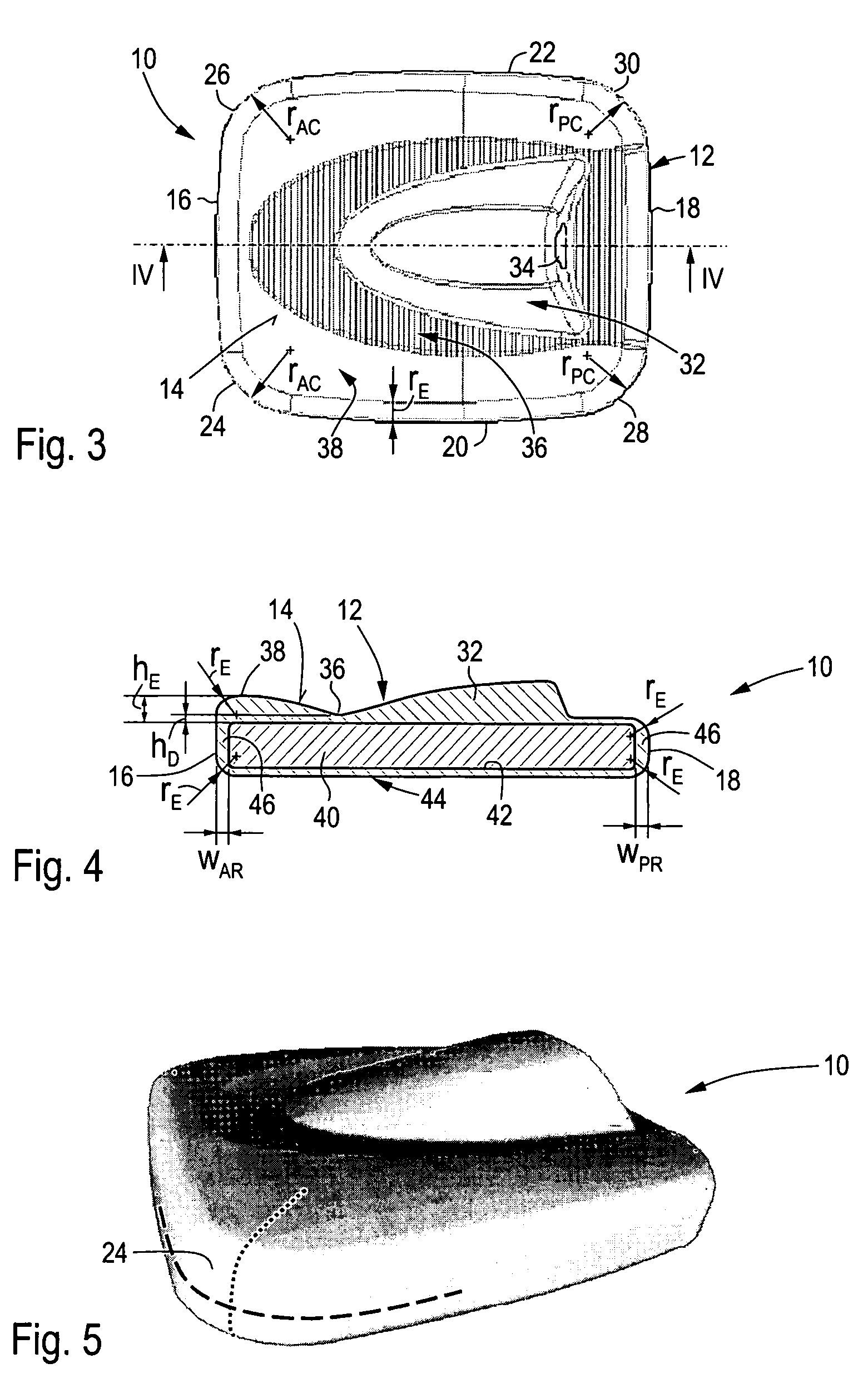

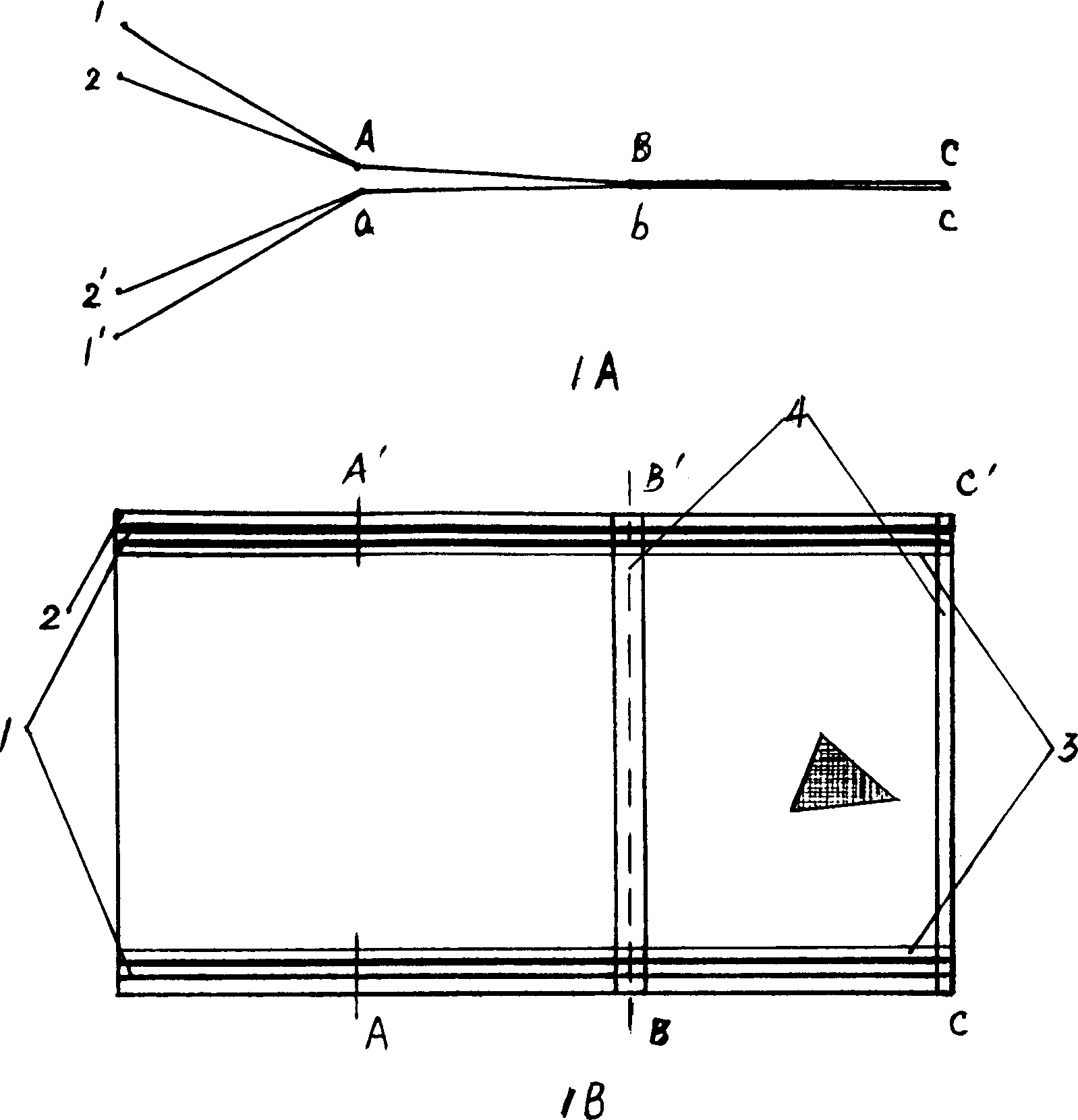

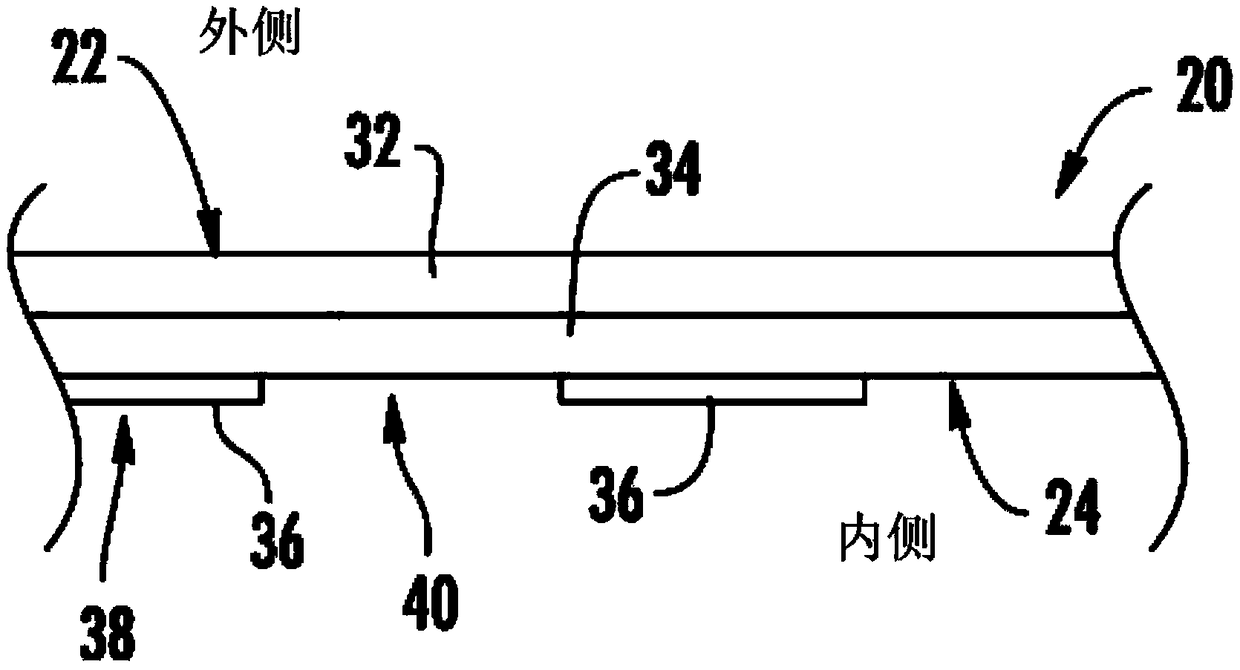

Seamless plastered, watertight and down penetration resistant down garment and method for making same

InactiveCN1864574AImprove waterproof performanceReduce seam widthOvergarmentsEngineeringLaser cutting

The present invention discloses one kind of adhered waterproof no-seamline down wear and its making process. The making process includes cutting patterns, cutting, laser cutting, hot adhering, filling down, supplementary material sewing and other steps. Unlike traditional sewing process, the fabric is separated into several checks and all the checks are no-seam adhered. The down wear has no seamline and no trouble of down escape through the seamline, and is waterproof and good-looked. In addition, the down wear with no seamline has improved windproof warming performance.

Owner:黄国钦

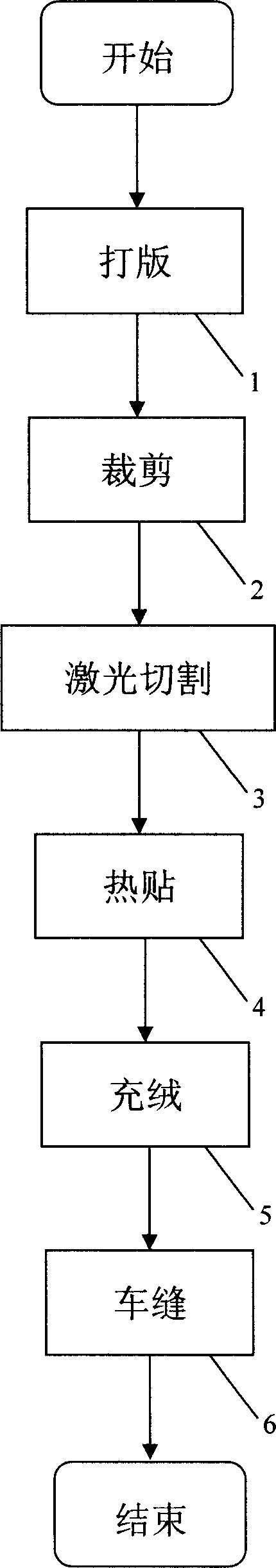

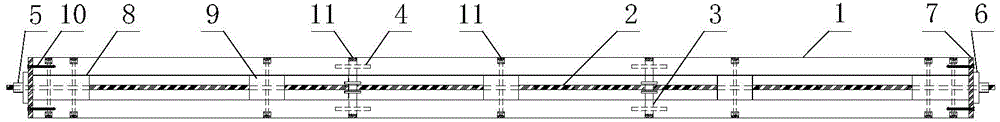

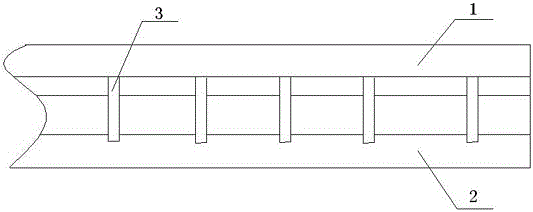

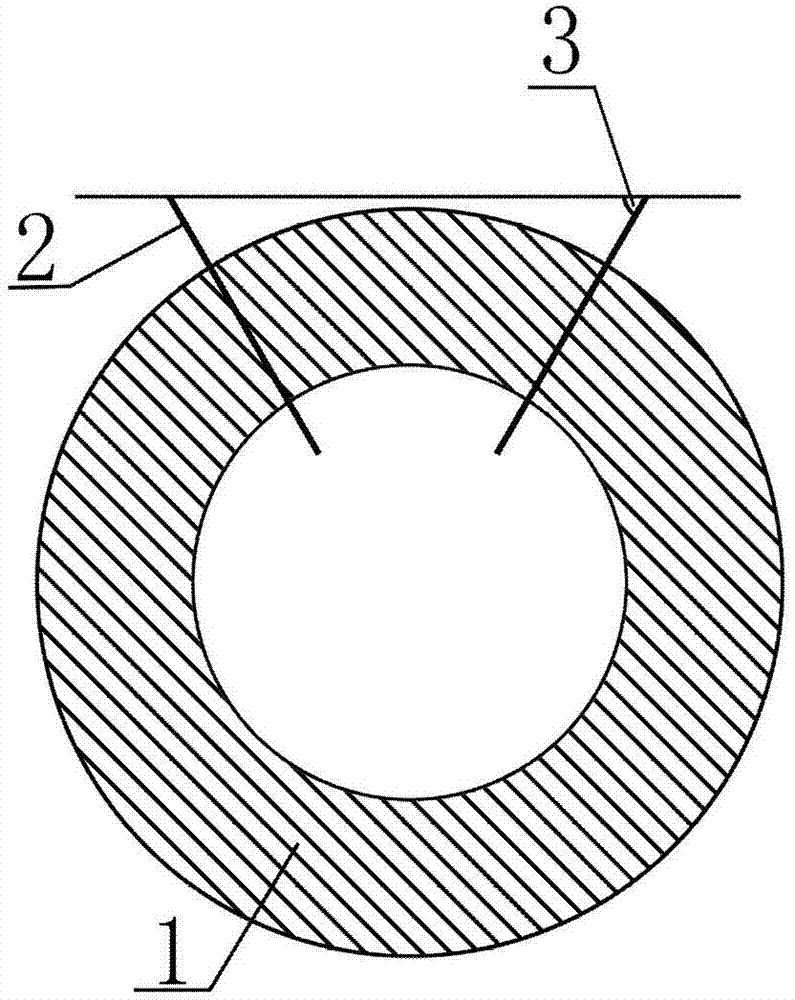

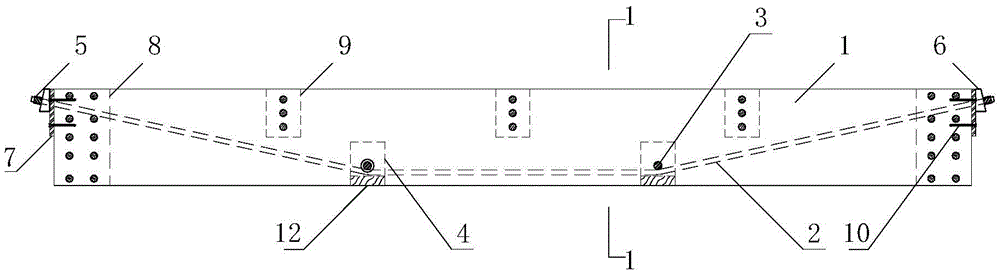

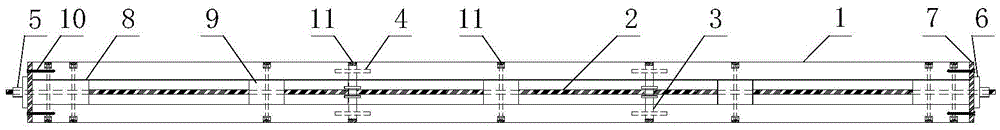

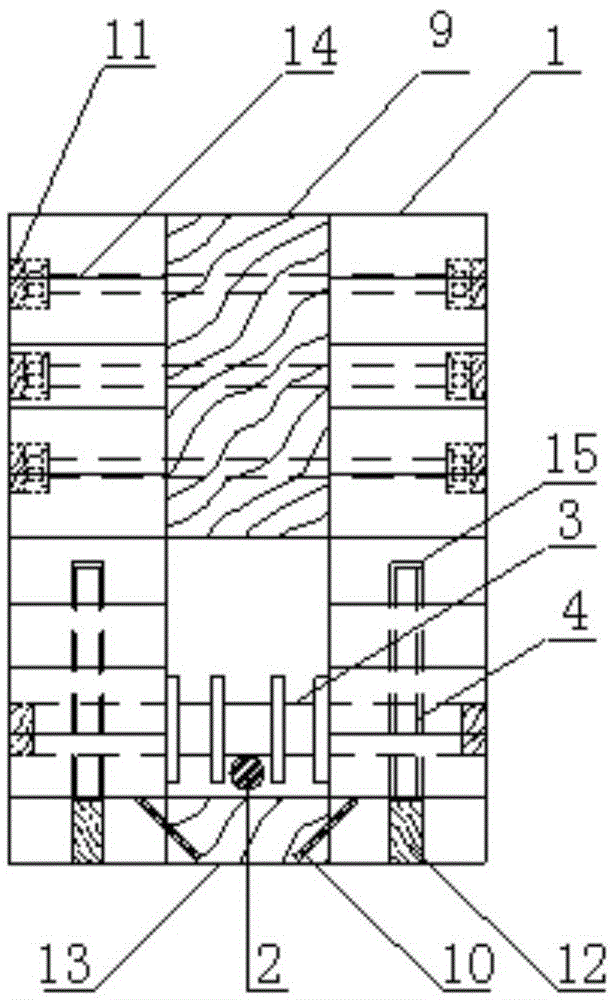

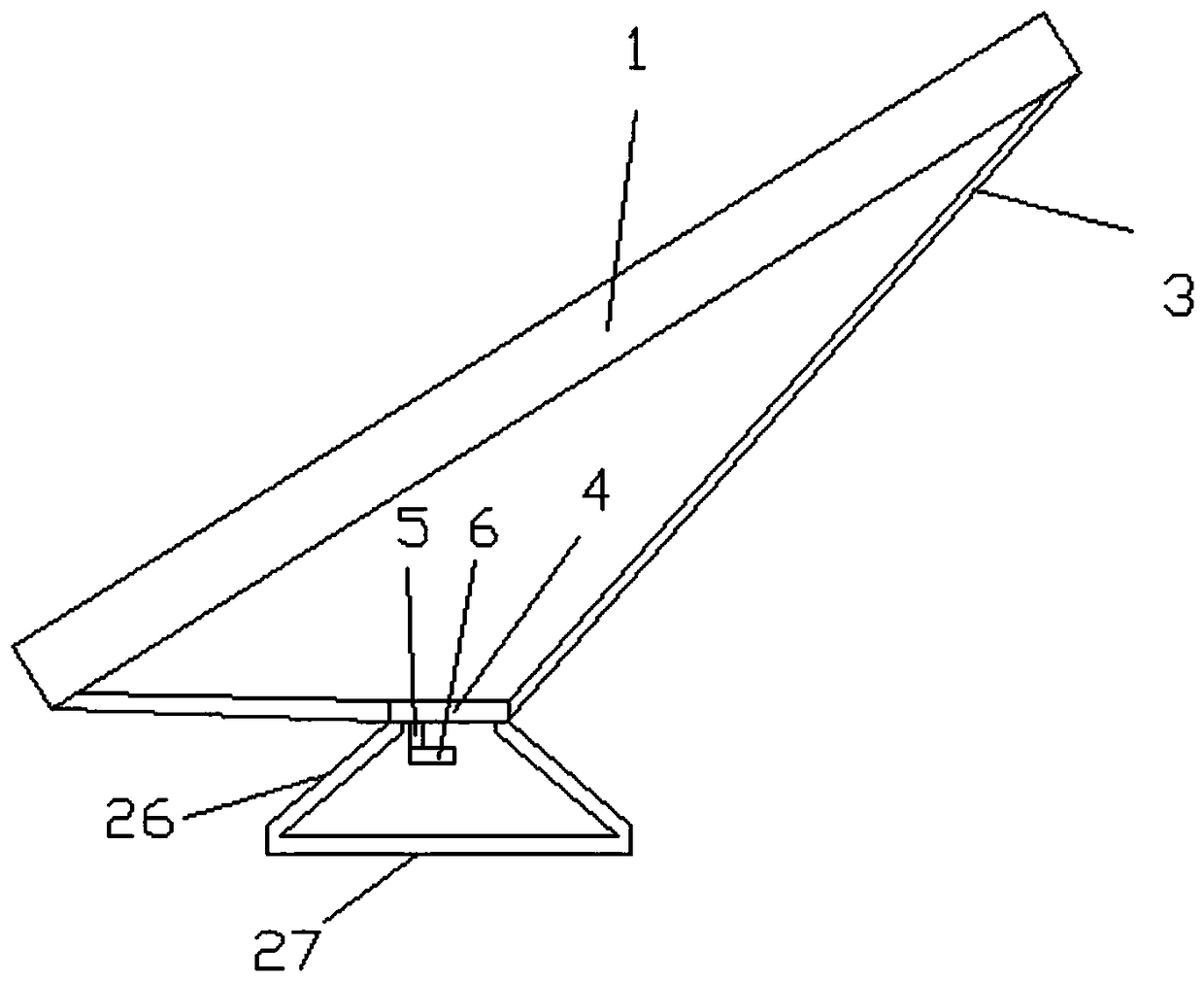

Concealed prestressed wood beam

ActiveCN104533014AImprove fire performanceIncreased durabilityBridge structural detailsGirdersPre stressWhole body

The invention discloses a concealed prestressed wood beam, which comprises a wood beam, one or more prestressed tendons, steering devices and anchoring devices, wherein the wood beam is a coupled beam, and cushion blocks between beams, a cushion block at an anchoring end, and bolts are arranged between two parallel beams which are connected to form a whole body; the one or more prestressed tendons are arranged in a middle gap of the coupled beam, and the two ends of the prestressed tendons are anchored at the beam end, on a column body or between the beams by the anchoring device; the middle part of each prestressed tendon is fixedly arranged in the middle of the coupled beam by the corresponding steering device, and each steering device comprises a pin shaft and a gluing steel plate; each gluing steel plate is fixedly arranged in a wood beam body or adhered to the inner side of the wood beam by adhesive resin, and each pin shaft passes through a pin shaft hole in the corresponding gluing steel plate and is transversely arranged in the middle gap of the coupled beam. The concealed prestressed wood beam provided by the invention has the advantages of high bearing capacity, light self weight, good fireproof performance, simple system, attractive appearance, industrial production, and quick installation. The concealed prestressed wood beam provided by the invention can be used in the fields of structures such as large-span buildings and bridges.

Owner:NANJING UNIV OF TECH

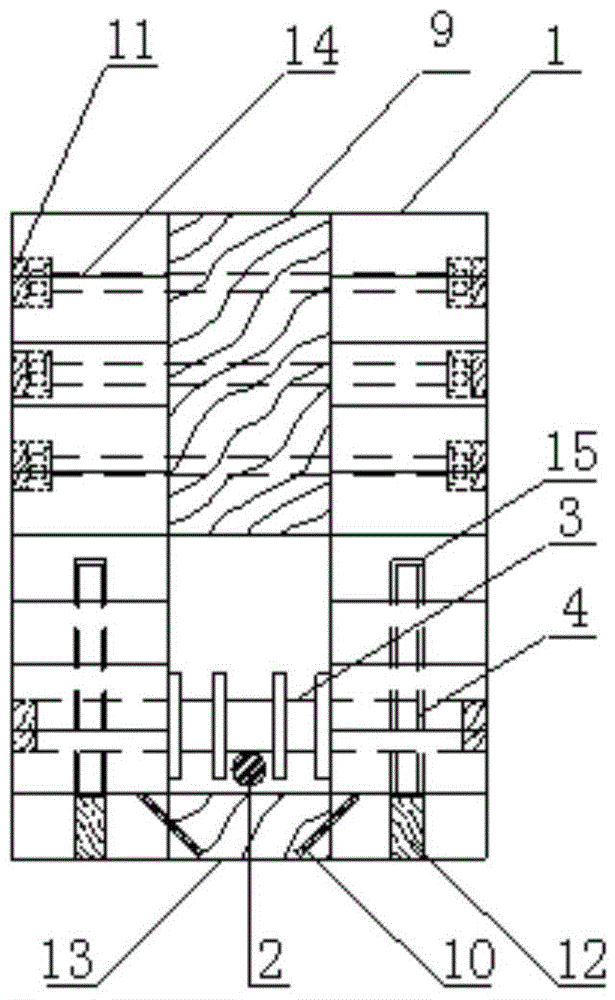

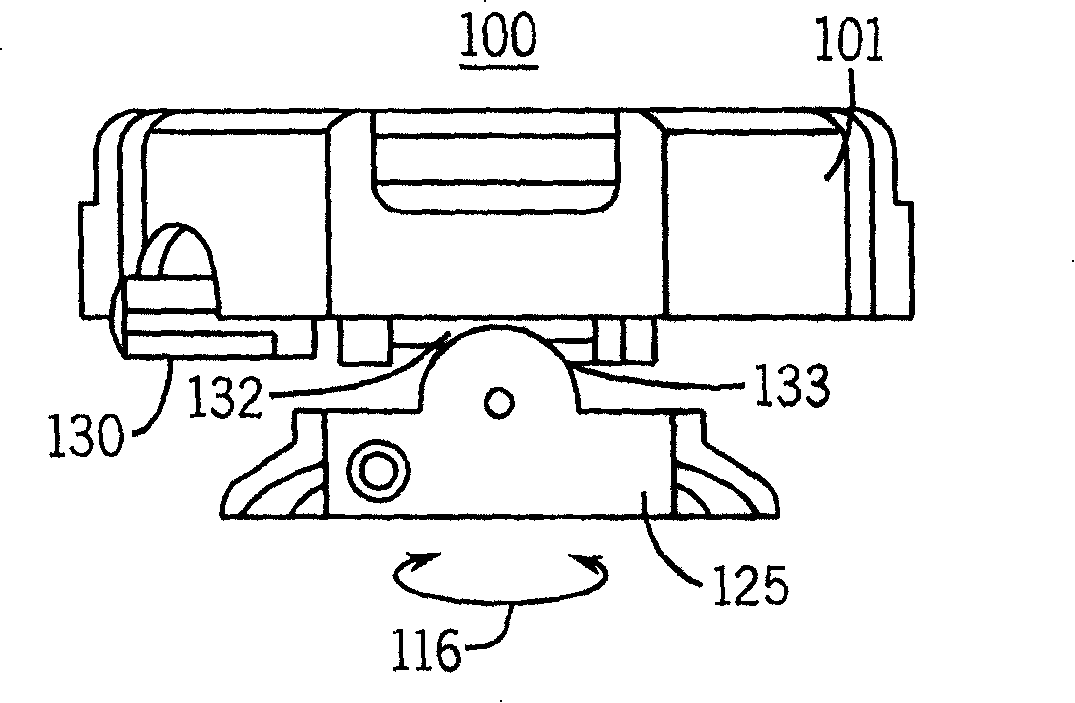

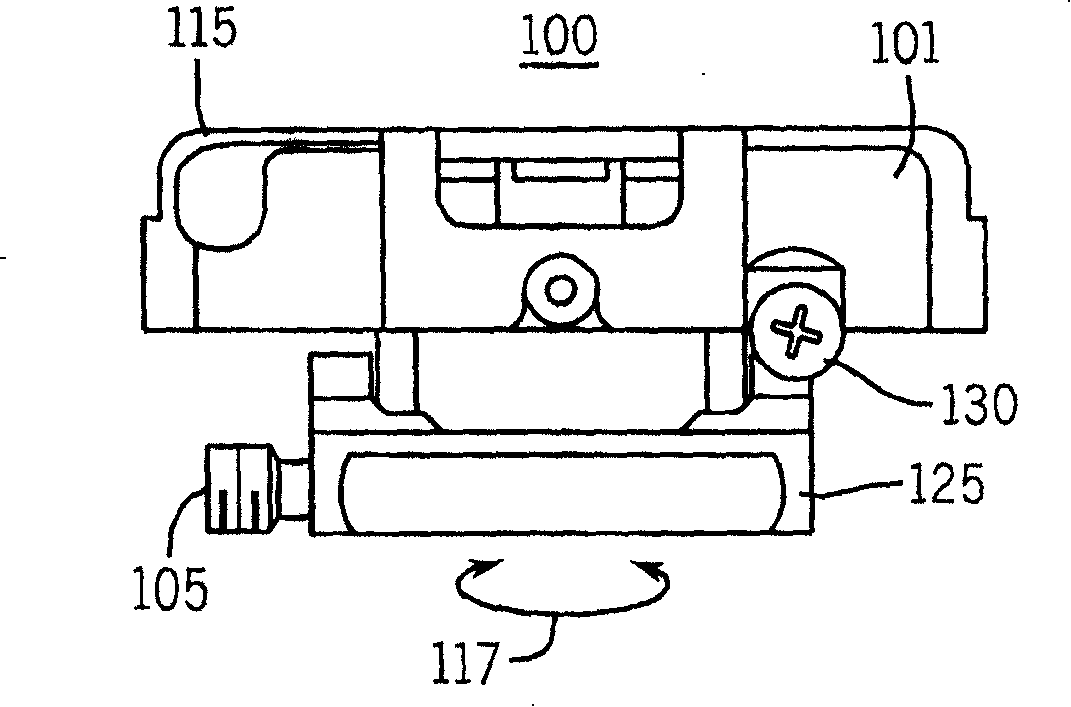

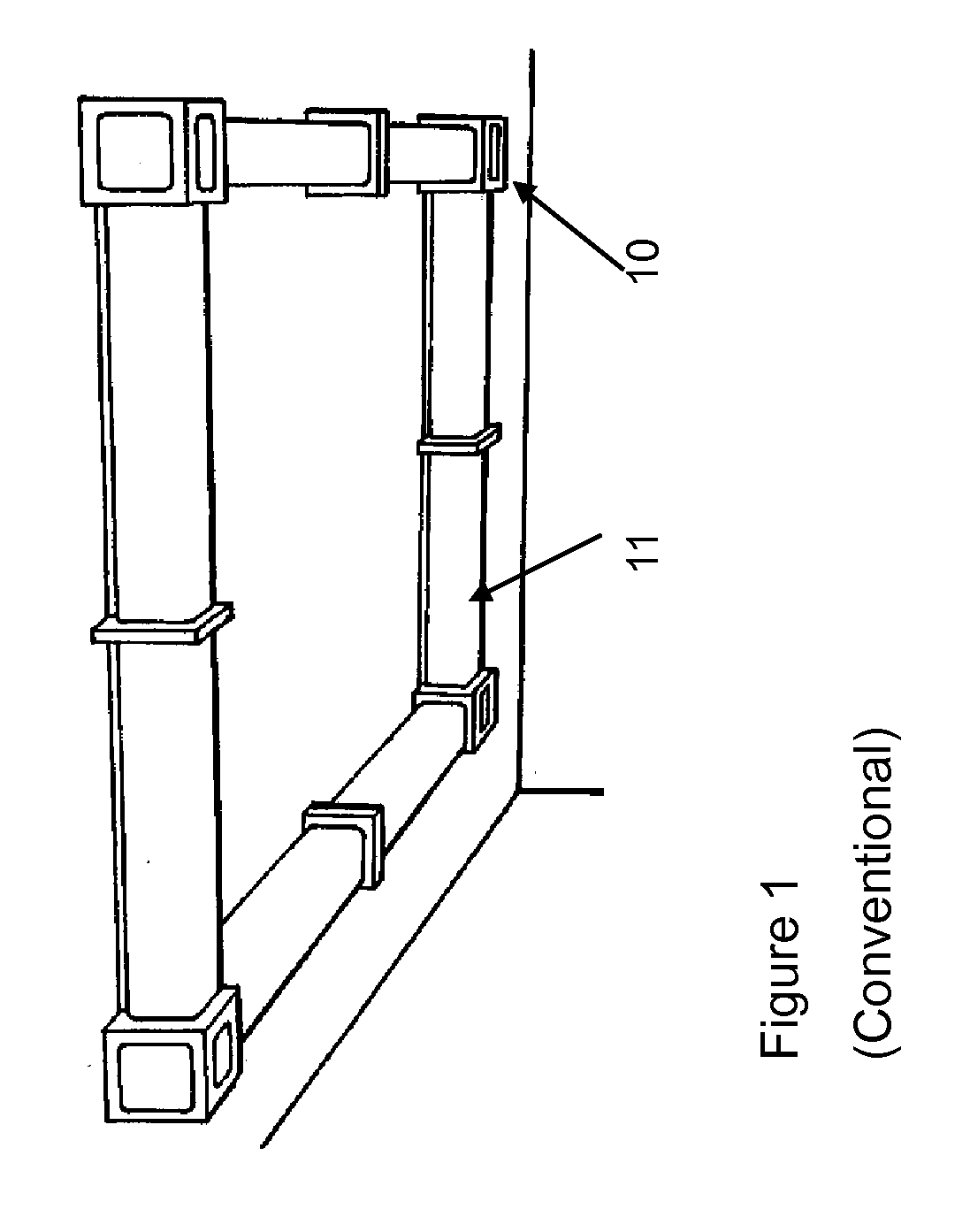

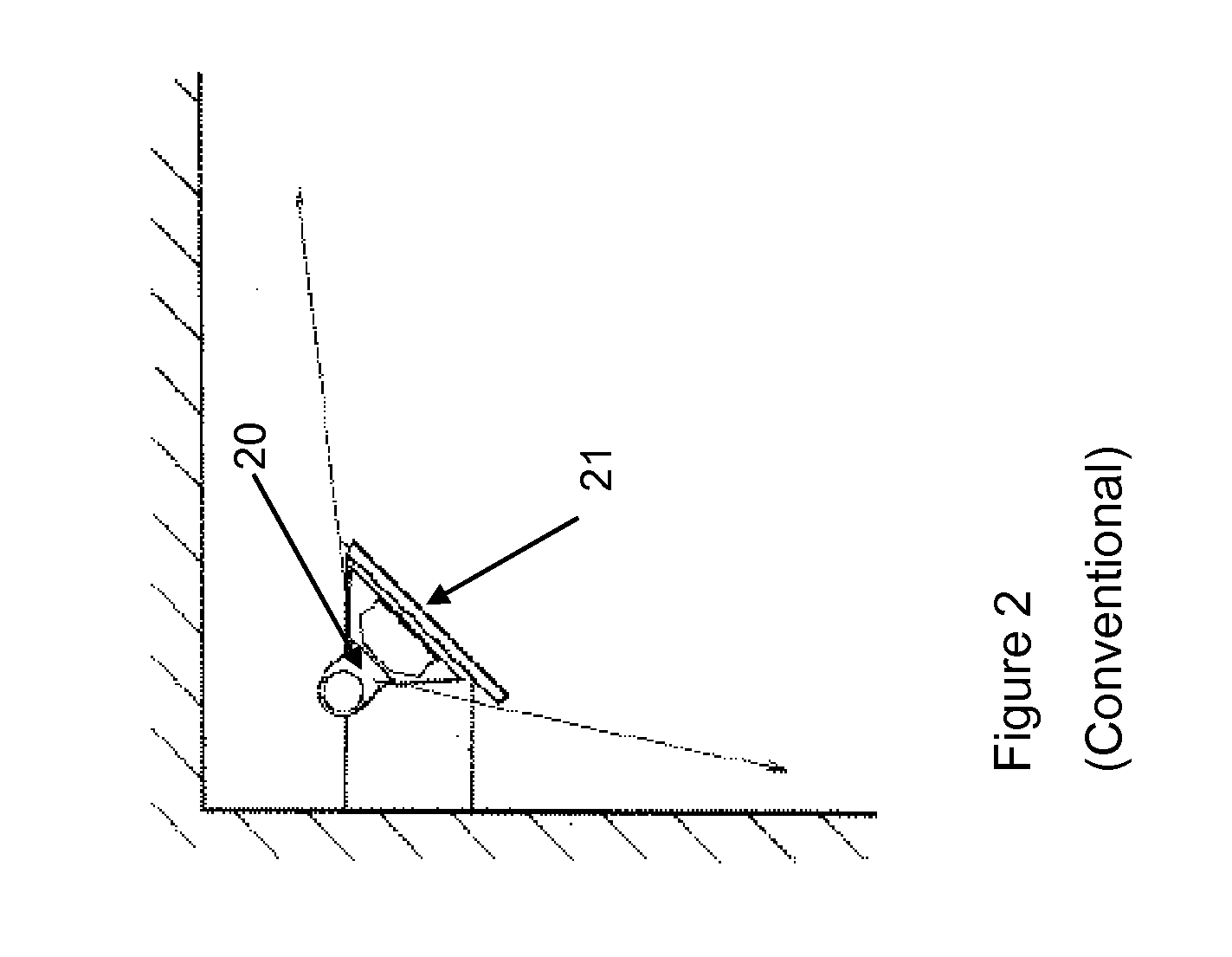

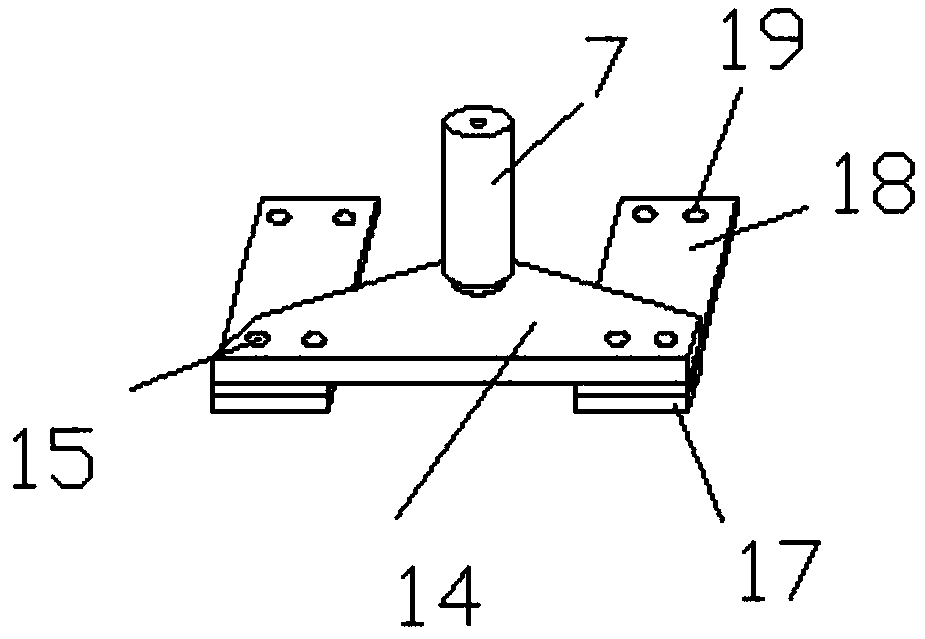

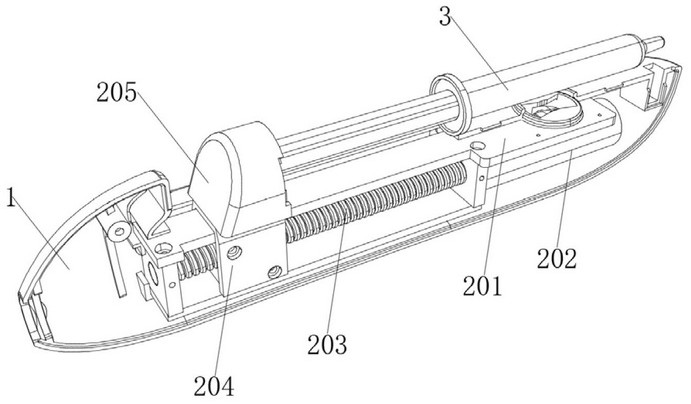

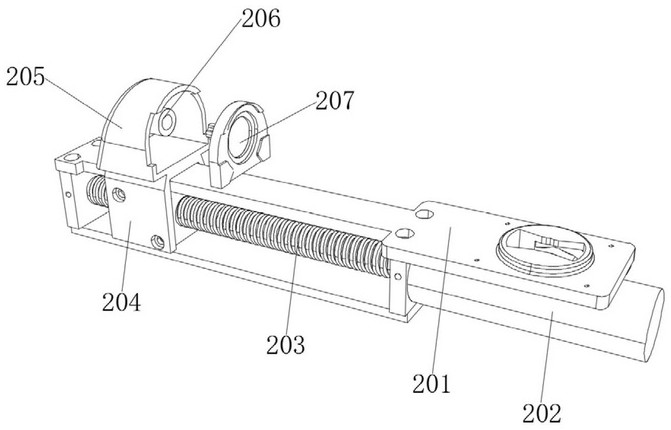

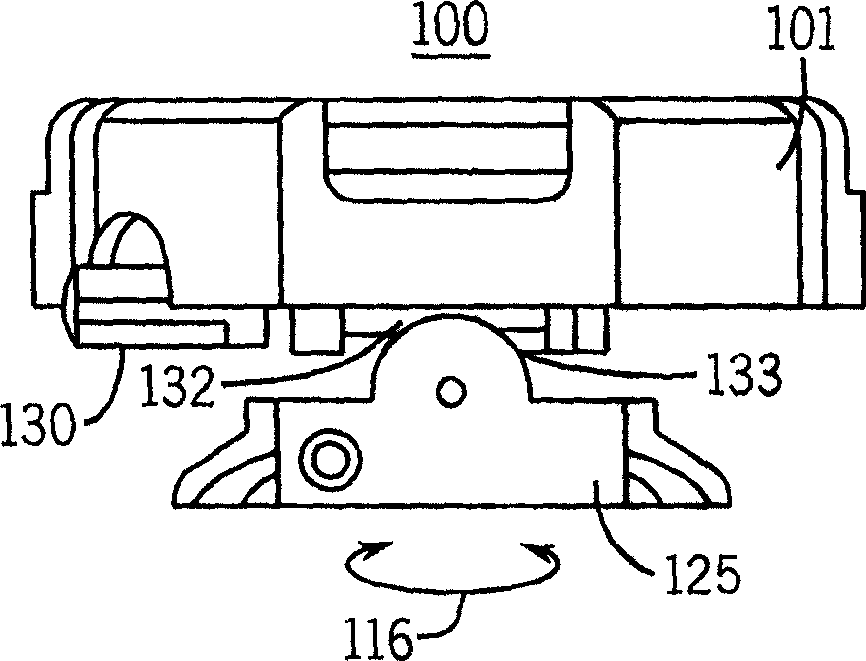

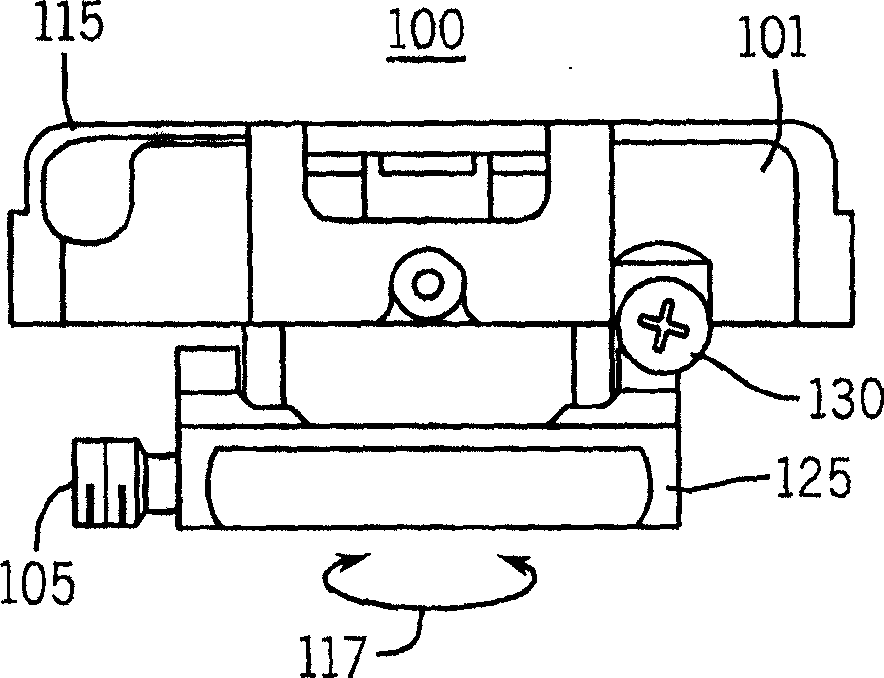

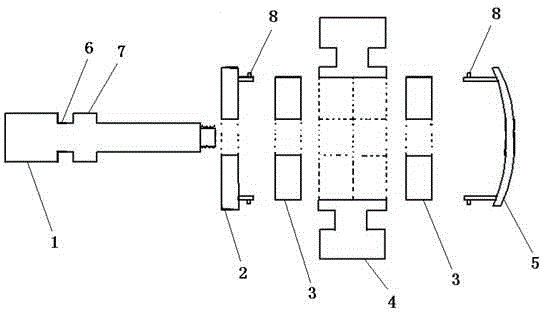

Projector mount

InactiveCN101226323AEasy to installComfortable appearanceProjectorsStands/trestlesSupporting systemProjection screen

A small projector mount for media projectors that enables the media projector's image to be fully aligned with the projection screen on which the image is displayed. Alignment of the mini projector mount is achieved via tilt, rotation and / or yaw adjustment mechanisms included in the mini projector mount. Small projector mounts can be mounted flush to the ceiling or mounted to an extension column or other intermediate support system. The quick release system allows the projector mounted to a small projector stand to be removed without obstructing the small projector stand. In addition, retractable members for achieving tilt, rotation and / or yaw adjustment are used.

Owner:PEERLESS INDS

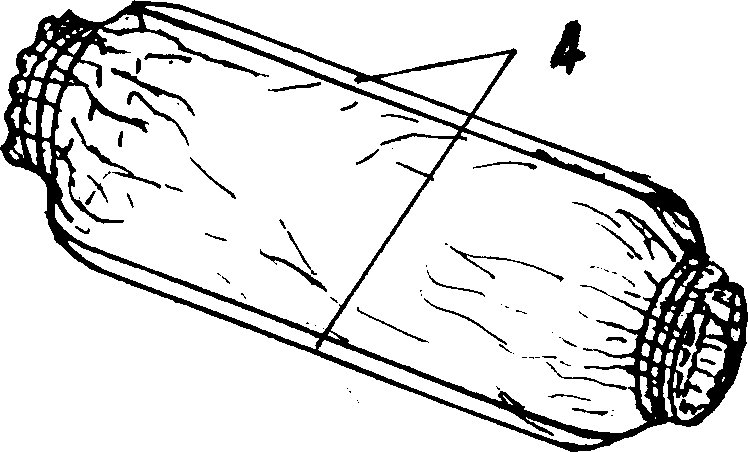

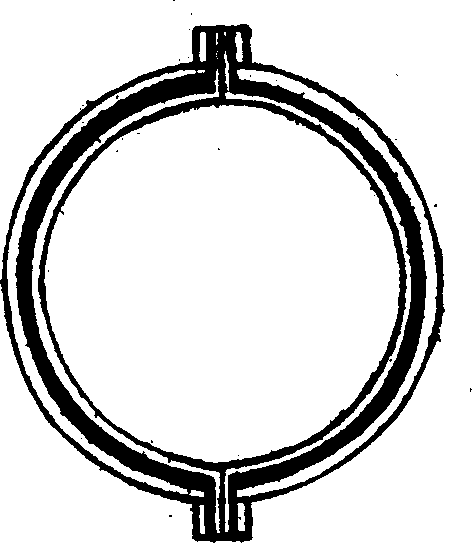

Technology for making oversleeve

The present invention relates to a new production process of sleeve protector, and is characterized by that the rib cuff elastic ring of each of two ends of said sleeve protector is a circular ring synthesized by two symmetrical notched rubber bands, and the number of the rib cuff elastic rings can be one or several bands, and said sleeve is a cylinder synthesized by two symmetric notched plane face fabrics, and the internal side of said sleeve protector has two but-welded seams and four folded selvages, and the rubber band and face fabrics can be adhered and fixed together by adopting the processes of collosed coating and plastic welding, so that the original traditional manual circumferential movement can be changed into the invented mechanical linear movement so as to raise its production efficiency.

Owner:上海蓝岛卫生用品有限公司

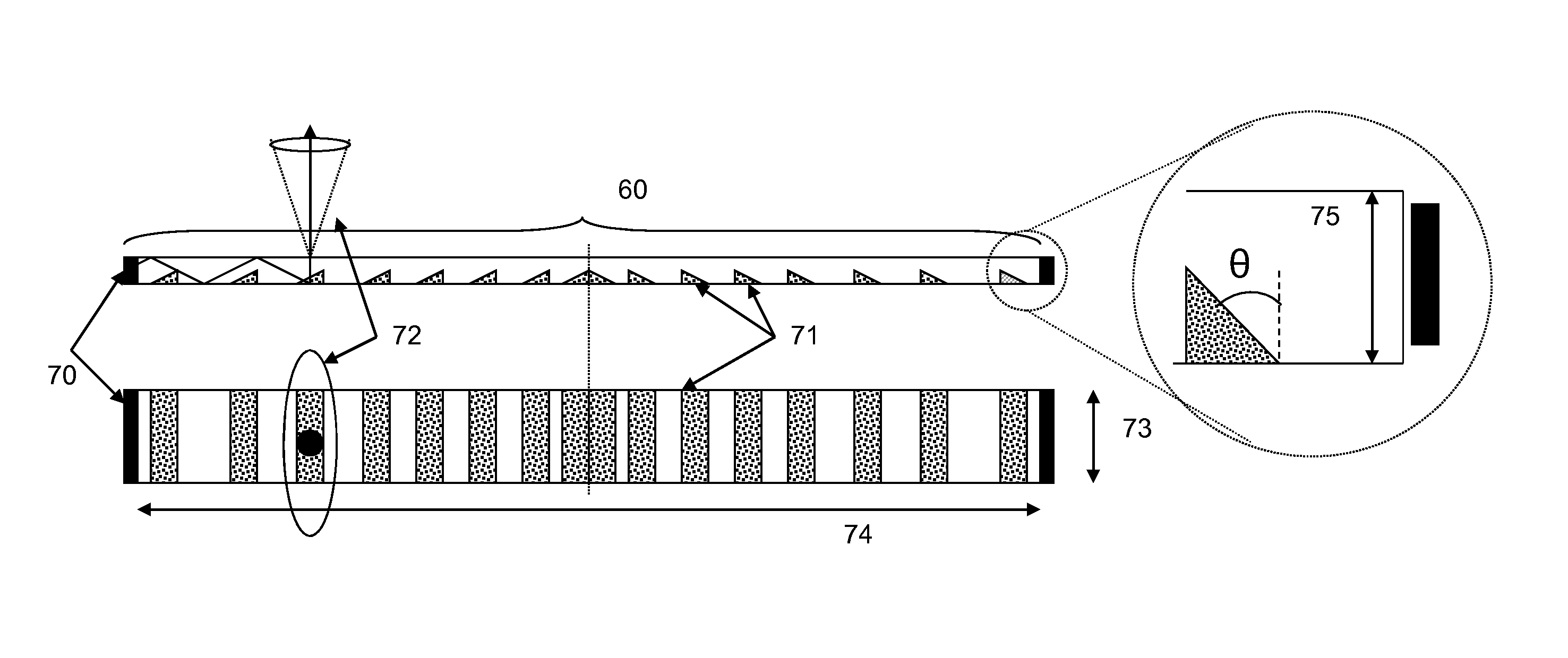

Indoor illumination system

InactiveUS20120182764A1Refining issueReduce shadowsPoint-like light sourceLighting support devicesDirect illuminationEffect light

A lighting system for an indoor room or space is designed to provide a diffuse, glare free source that illuminates the room from the cornice, or a similar location around the join between the walls and ceiling. This may be achieved via a direct source of illumination at the cornice location, or by projecting illumination from a remote source. The lighting system is further designed to allow for illumination of certain areas of the cornice, and hence the room, whilst leaving other parts dark. There are multiple advantages of an adaptable system such as this, but in particular the lighting conditions can be adjusted for optimum lighting levels, for example dimming selected areas when viewing a television.

Owner:SHARP KK

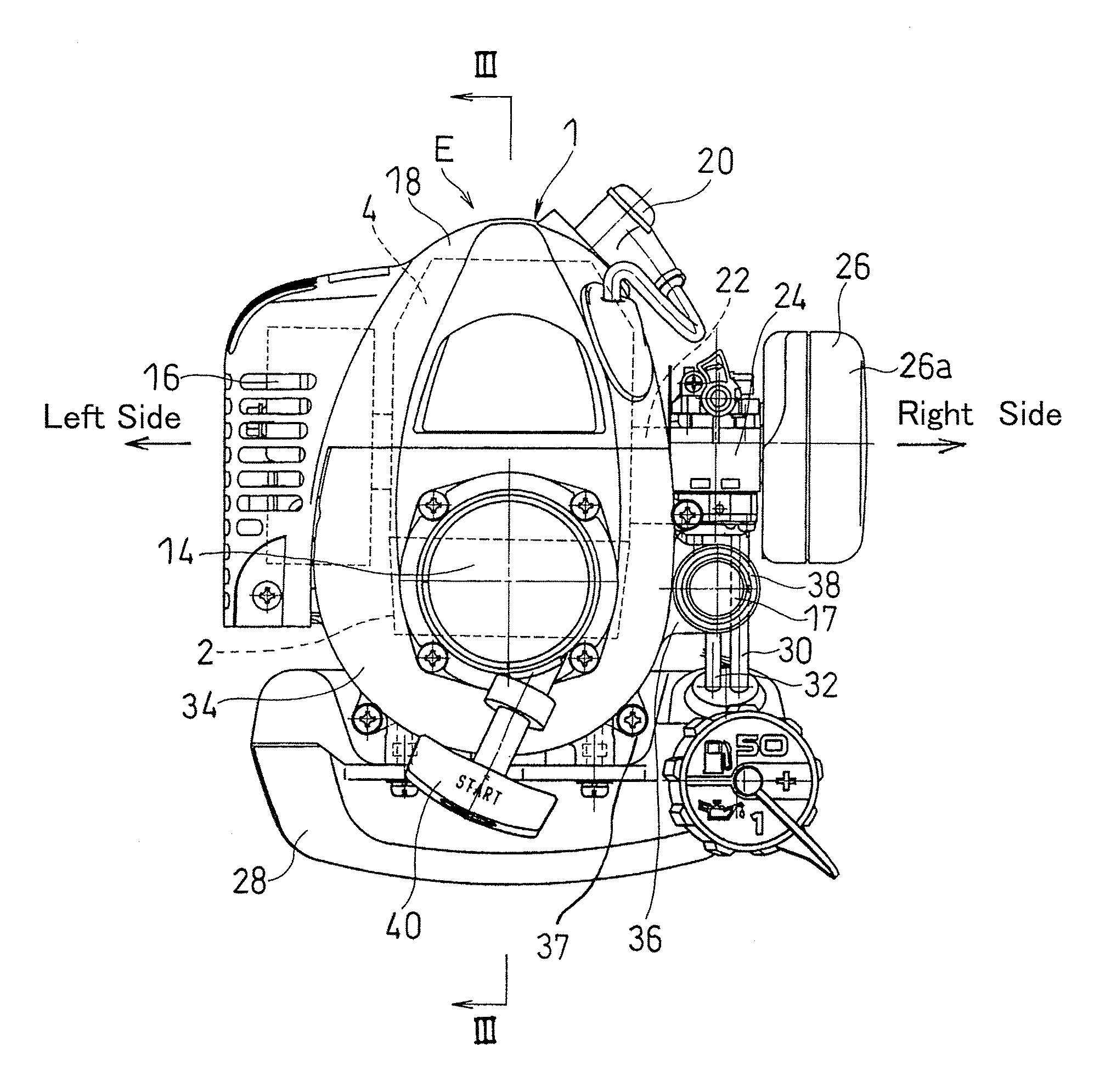

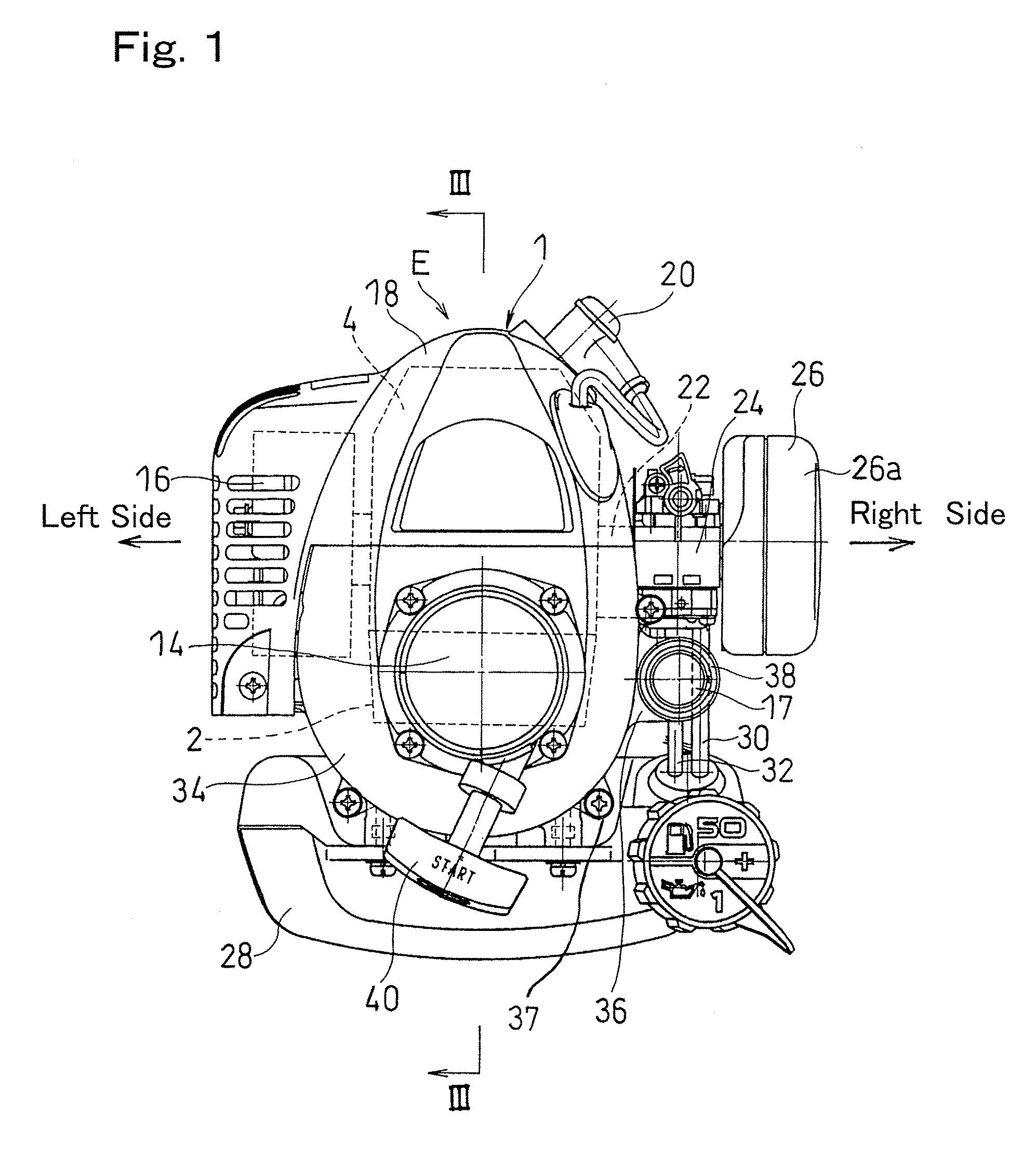

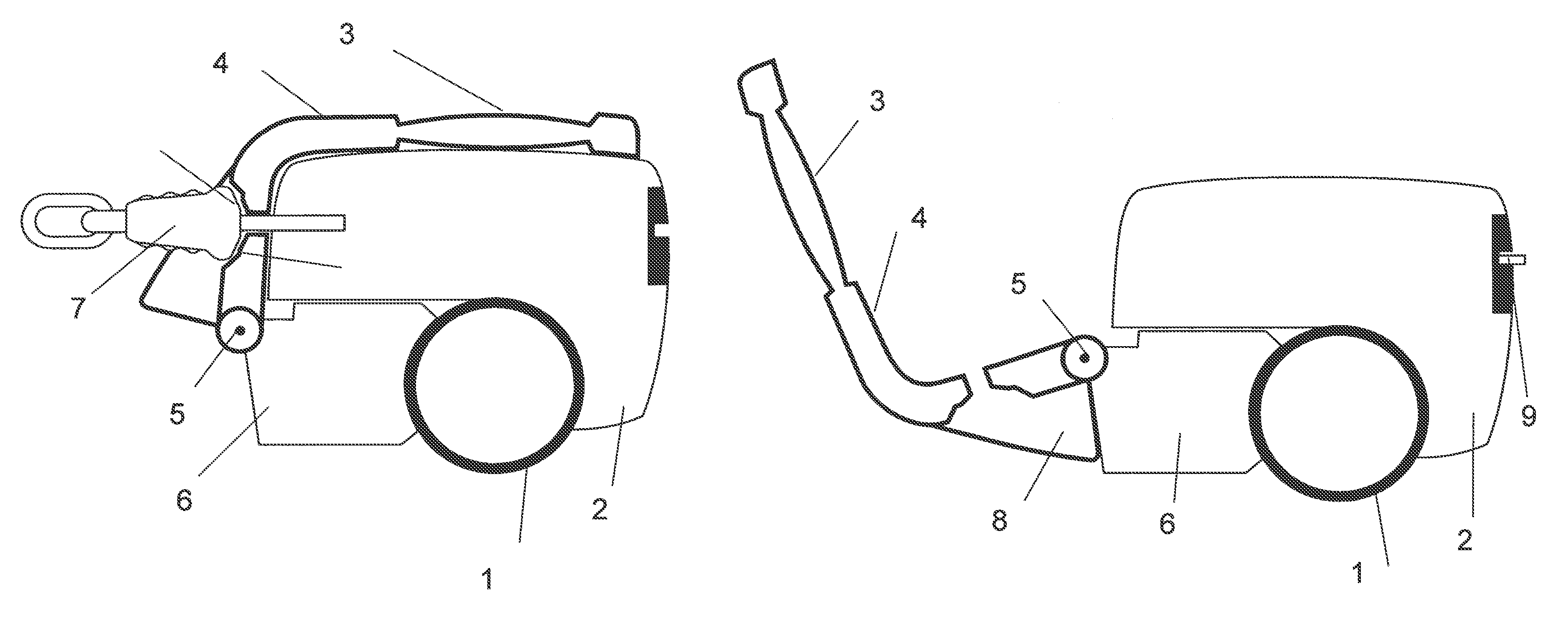

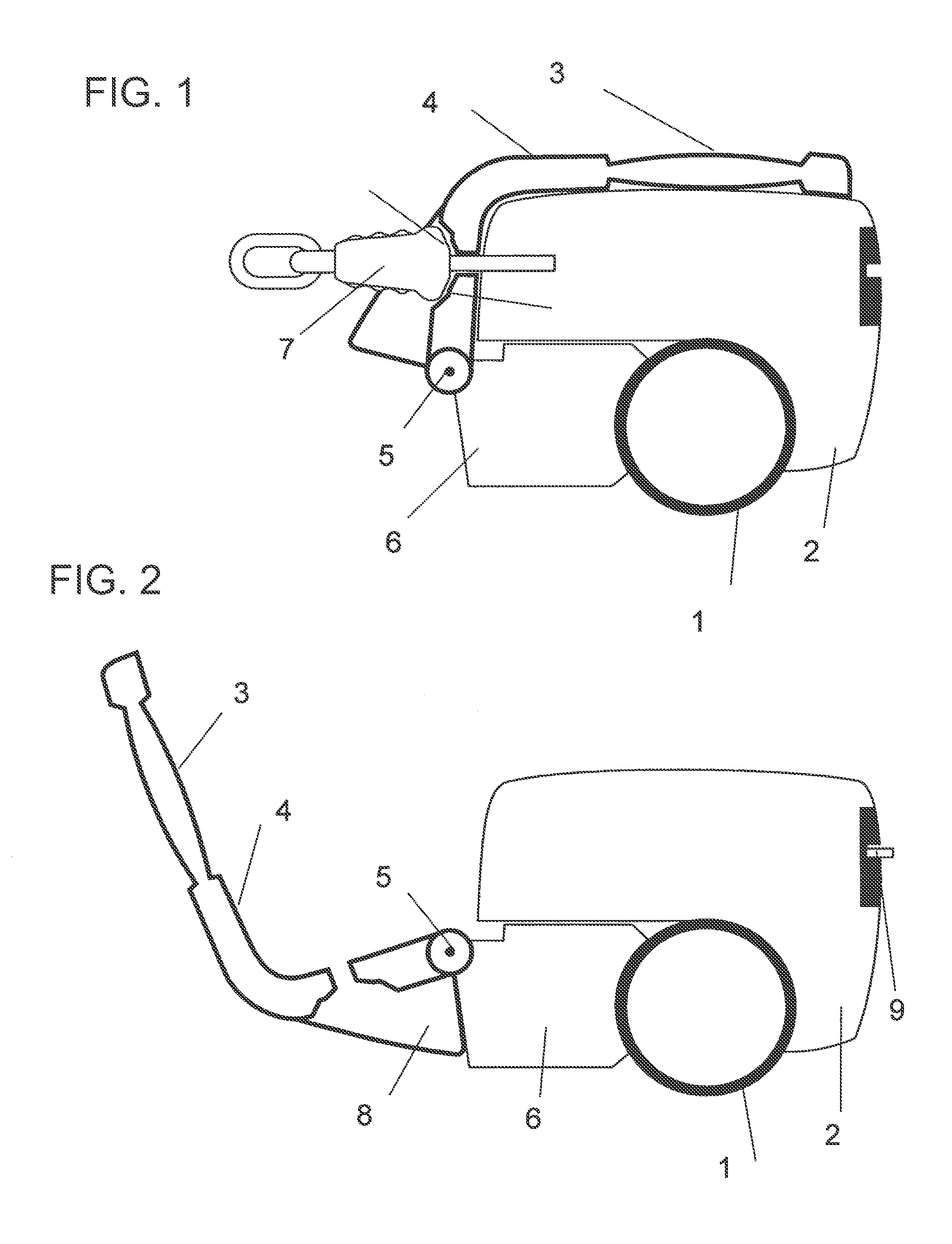

Combustion engine with a priming pump

InactiveUS20080092840A1Easy to operateStable supportMetal sawing devicesLevel controlFuel supplyEngineering

A combustion engine includes a carburetor, which is a fuel supply device for introducing fuel into an intake air of the engine, and a fan housing for enclosing a cooling fan mounted on a front end portion of a crankshaft. The fan housing is formed with a flange so as to extend towards a position proximate to the carburetor, and a manually operable priming pump is fitted to the flange.

Owner:KAWASAKI HEAVY IND LTD

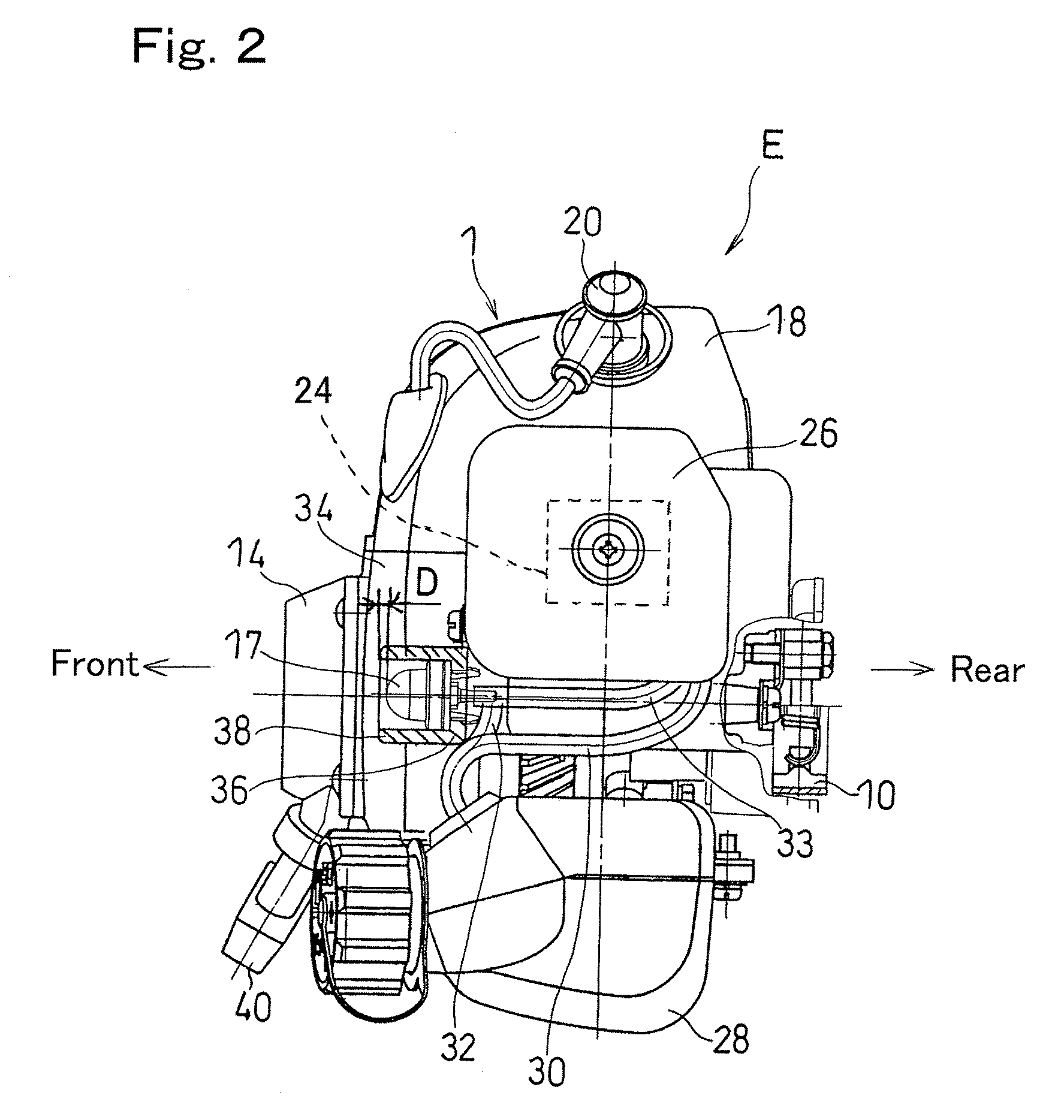

Wearable sound feedback system based on brain electrophysiological signals

PendingCN107802263AComfortable to wearExquisite designSensorsTelemetric patient monitoringAuditory systemEngineering

The invention provides a wearable sound feedback system based on brain electrophysiological signals. By virtue of the system which is worn on the head of an individual, the brain electrophysiologicalsignals of the individual are collected and extracted; then, on the basis of the characteristics of the brain electrophysiological signals, specific sound signals are generated in real time; and the sound signals are fed back to an auditory system of the individual in real time, so that real-time sound feedback based on the characteristics of the brain electrophysiological signals of the individual is achieved. According to the system, personalized sound feedback for the same individual is achieved, and meanwhile, real-time sound feedback is achieved.

Owner:候俊英

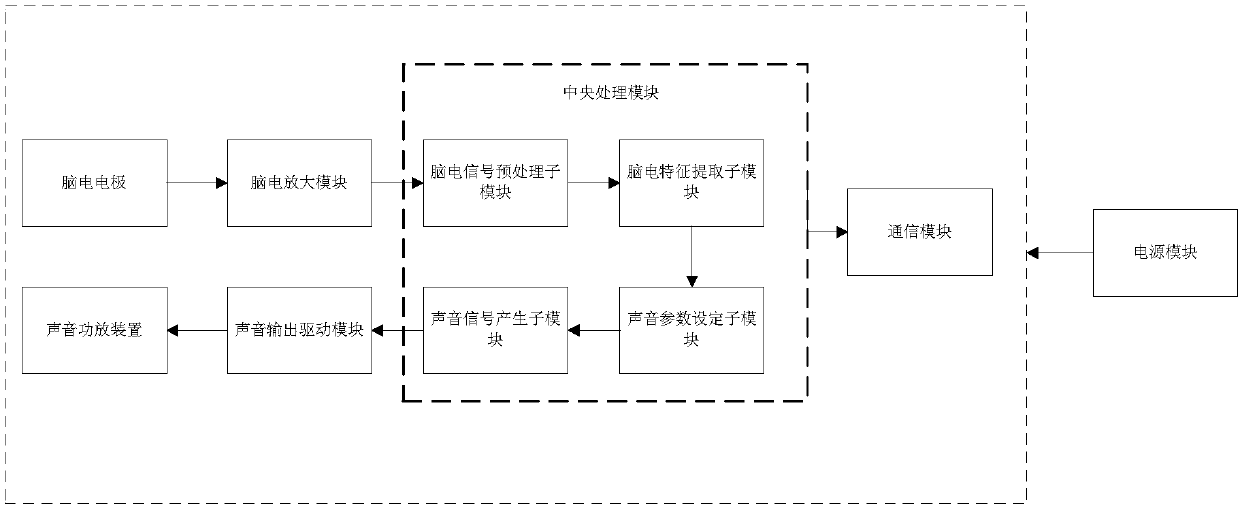

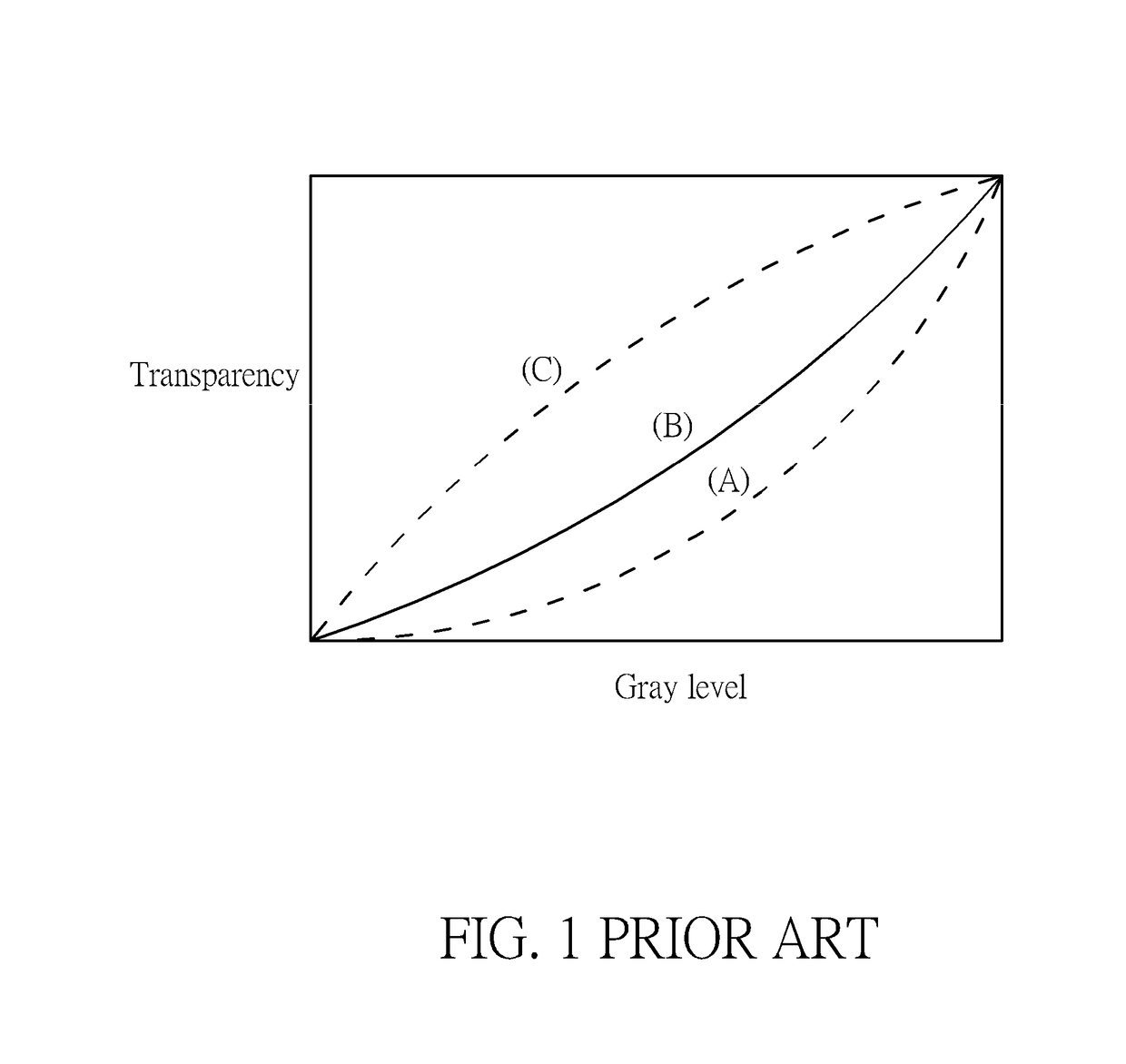

Image adjusting method and related display

ActiveUS9858850B2Improve image qualityDecrease in luminanceTelevision system detailsStatic indicating devicesComputer graphics (images)Display device

An image adjusting method and a related display are applied to automatically adjust luminance of an image according to analyze of a gray level histogram of the image. The image adjusting method includes generating the gray level histogram of the image, dividing the gray level histogram into at least one first zone and one second zone, comparing a total amount of pixels in the first zone with a threshold, and utilizing a modification function to adjust luminance of each pixel within the first zone according to a comparison result. A grey level of the first zone is greater than a grey level of the second zone. Luminance of the first zone is decreased by the modification function while the total amount of pixels in the first zone is greater than the threshold.

Owner:BENQ CORP +1

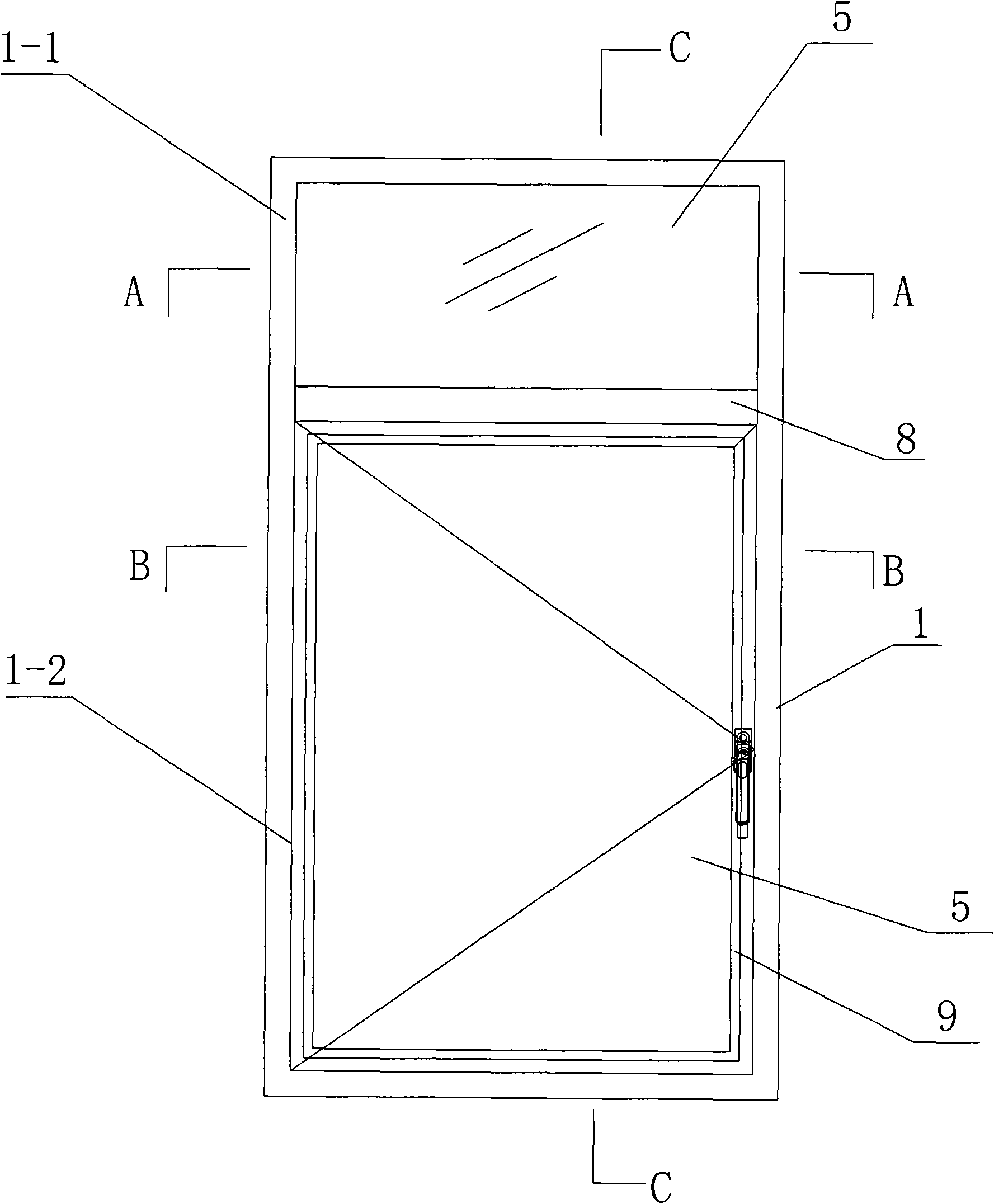

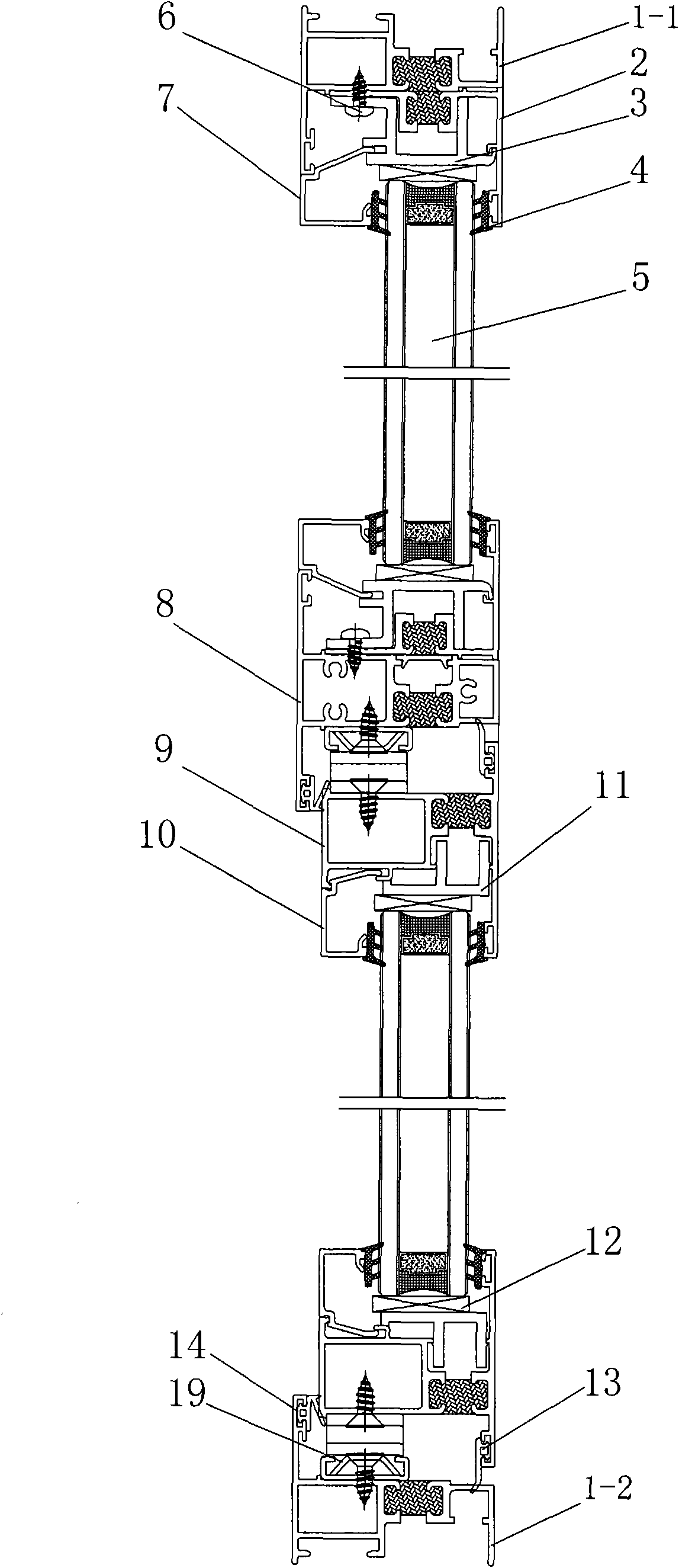

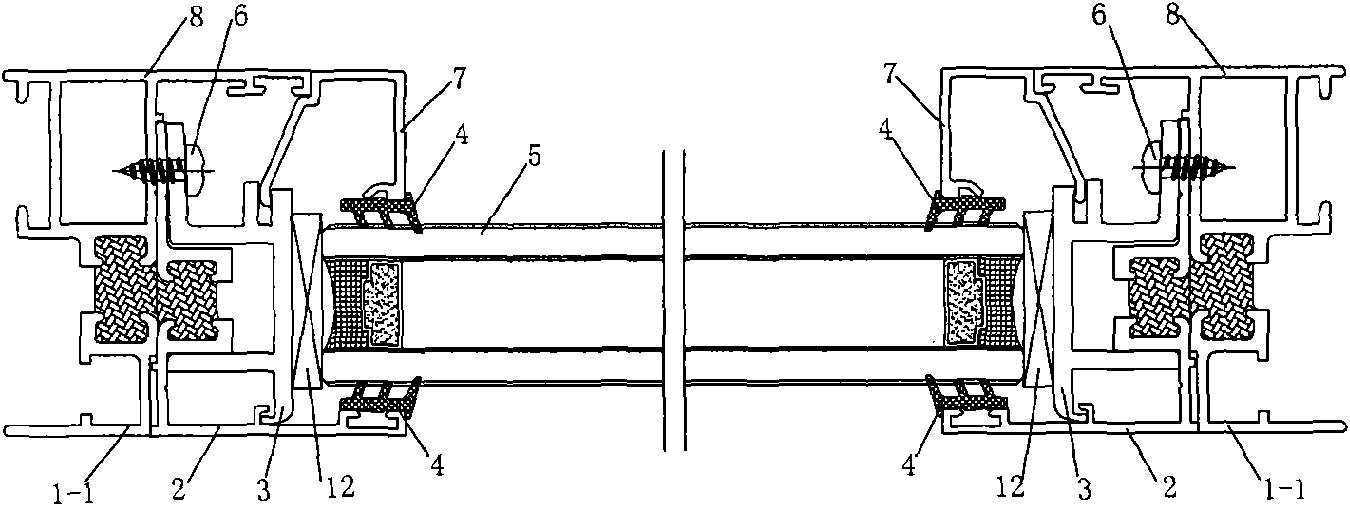

Energy-saving casement window

The invention relates to a building door and window, in particular to an energy-saving casement window with good sealing property. The invention aims to provide an energy-saving casement window with good sealing property, which has the characteristics of simple reasonable structure, factory production, quick and convenient mounting and better heat insulating and energy saving effect. The inventionadopts the technical scheme that the energy-saving casement window is provided with a frame comprising a left rim and a right rim which are opposite to each other, as well as an upper rim and a lowerrim which are vertically connected. The energy-saving casement window is characterized in that the frame is divided into a fixed frame and an open frame through a mullion; the fixed frame is internally embedded with glass, and the open frame is provided with at least one movable sash which is connected with the open frame through a friction hinge; and the movable sash is also internally embeddedwith glass.

Owner:杭州新域郡邦建筑材料有限公司

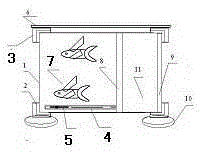

Glass-bed fish bowl

InactiveCN105325349ANice appearanceUnique appearancePisciculture and aquariaEngineeringToughened glass

The invention discloses a glass-bed fish bowl, which comprises a double-bed-sized fish bowl made of tempered glass, wherein each joint of the bottom of the fish bowl is wrapped with a wood material layer, the wood material layer is externally wrapped with a metal material layer, the two broadsides of the fish bowl are provided with a sliding door, a partition plate is arranged in the fish bowl, and each corner of the bottom of the fish bowl is provided with a conical spring support made of iron. The glass-bed fish bowl disclosed by the invention is beautiful and unique in appearance; and people sleeping on the glass-bed fish bowl feel cool and comfortable in summer, so that people fall asleep easily after a hard day's work.

Owner:李星明

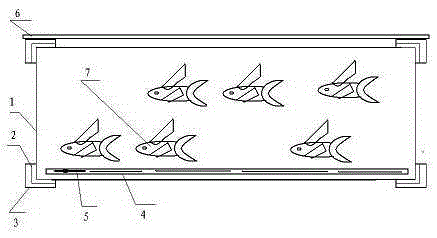

Control system of intelligent reminding device for incorrect sitting posture

InactiveCN112137292AVersatileEasy to installStuffed mattressesMeasurement devicesLiquid-crystal displayLaser ranging

The invention provides a control system of an intelligent reminding device for incorrect sitting posture, and relates to the field of incorrect sitting postures. The control system is composed of a main control single-chip microcomputer, an OLED liquid crystal display module, a laser ranging module, a pressure monitoring module, a sound prompt module, a key control module and a power supply module. According to the invention, the system realizes multi-dimensional comprehensive monitoring, and is humanized in design. Different wrong sitting postures such as humpback sitting, prone sitting and inclined sitting are monitored in an up-and-down and left-and-right multi-dimensional mode, and reminding threshold values such as pressure and distance difference are customized by the user accordingto the actual situations such as different heights and weights of students and different sizes of chairs. According to the set parameters, the device intelligently judges the sitting posture of the student, and once the sitting posture is incorrect, correction is reminded in time. The device also has the functions of sedentariness duration reminding and winter heating. The device is good in expansibility, a WIFI module can be added in the later period, and parents can check the sitting posture condition of the child on a mobile phone.

Owner:方翊霖

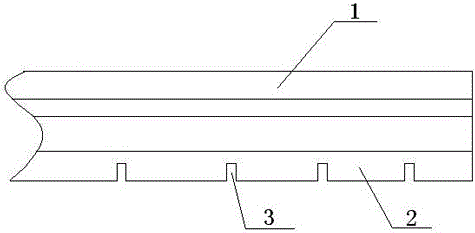

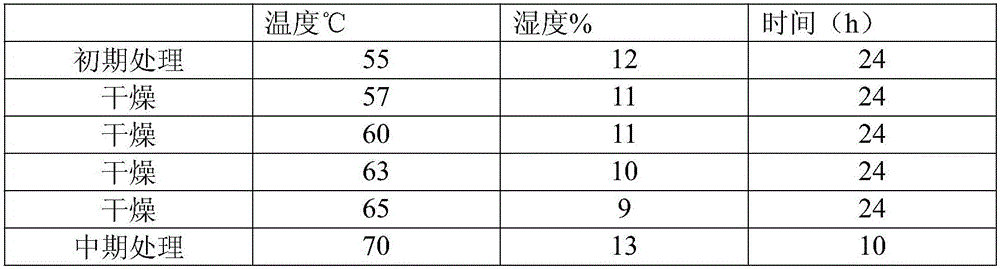

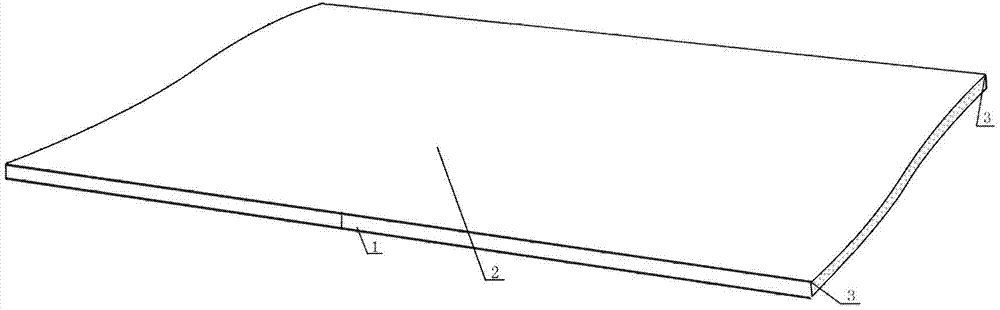

Two-layer solid wood composite floorboard and manufacturing method thereof

InactiveCN106182216AReduced stabilityGuaranteed stabilityWood veneer joiningWood layered productsSolid woodTransverse groove

A two-layer solid wood composite floor and a preparation method thereof, which belong to the technical field of wood processing. The two-layer solid wood composite floor is made by bonding a surface plate and a base plate. The wood grain direction of the surface plate and the base plate is the same, and one side of the base plate has a transverse groove , one or the other side of the substrate with grooves is bonded to the back of the panel to make solid wood composite flooring. The preparation method is completed by adopting the steps of separately drying the surface plate and the base plate, slotting the base plate, hot-pressing the surface plate and the base plate, and the like. The solid wood composite floor of the present invention is a two-layer floor combined with wood grain vertically, which saves wood resources, reduces costs, reduces the amount of glue coating, reduces the amount of formaldehyde release, ensures environmental protection, and solves the stress caused by the two layers being in the same direction. problem, to ensure the stability of the floor.

Owner:吴殿满 +1

Trimming-free novel flexible foam rubber and plastic heat insulation product and preparation method thereof

The invention provides a trimming-free novel flexible foam rubber and plastic heat insulation product and a preparation method thereof. By adopting a multi-roll calender and additionally arranging an excess material recovery device in an extrusion and trimming process, the surface of a product is smooth, and the side surface of the product is not trimmed and has no broken holes. The interior of the novel flexible foam rubber and plastic heat insulation product is uniform in foaming, the surface of the product is smooth and has no die lines, the novel flexible foam rubber and plastic heat insulation product has high tear strength, the edges are comfortable, and the transverse thickness is uniform. The product is not trimmed and has no broken holes, a broken hole heat dissipation channel is plugged, so that vacuum water absorption and heat conductivity coefficient are lowered and the heat insulation effect is improved. Furthermore, the product is not trimmed, thus improving the raw material use efficiency, lowering the cost, generating no solid waste, and being beneficial to environment conservation, energy conservation and emission reduction.

Owner:HEBEI HUAMEI CHEM & BUILDING MATERIALS GRP

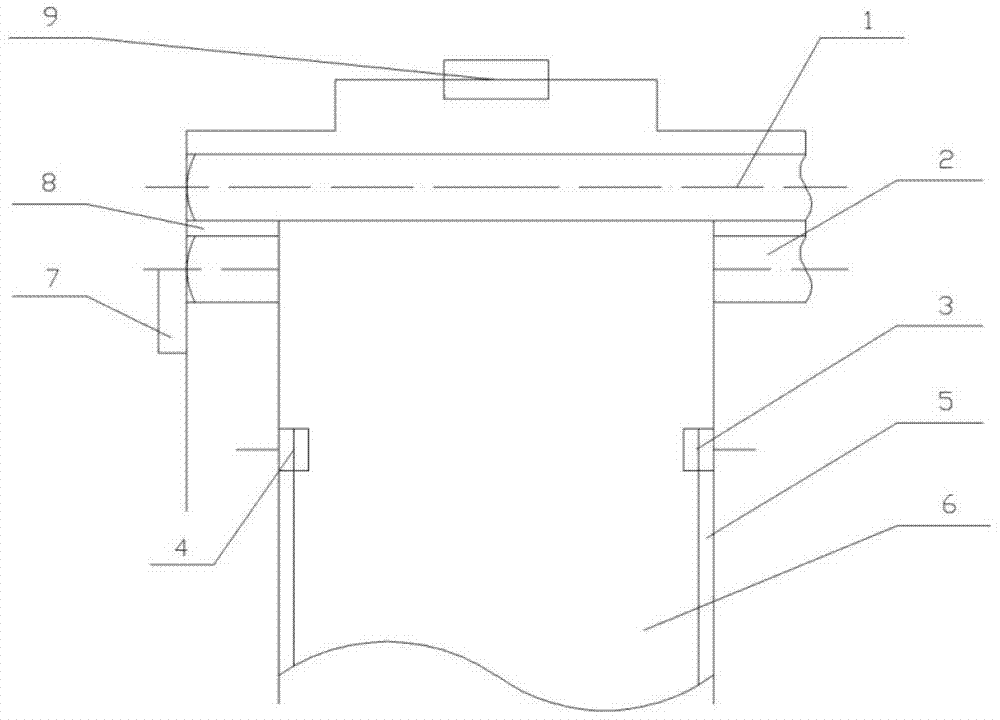

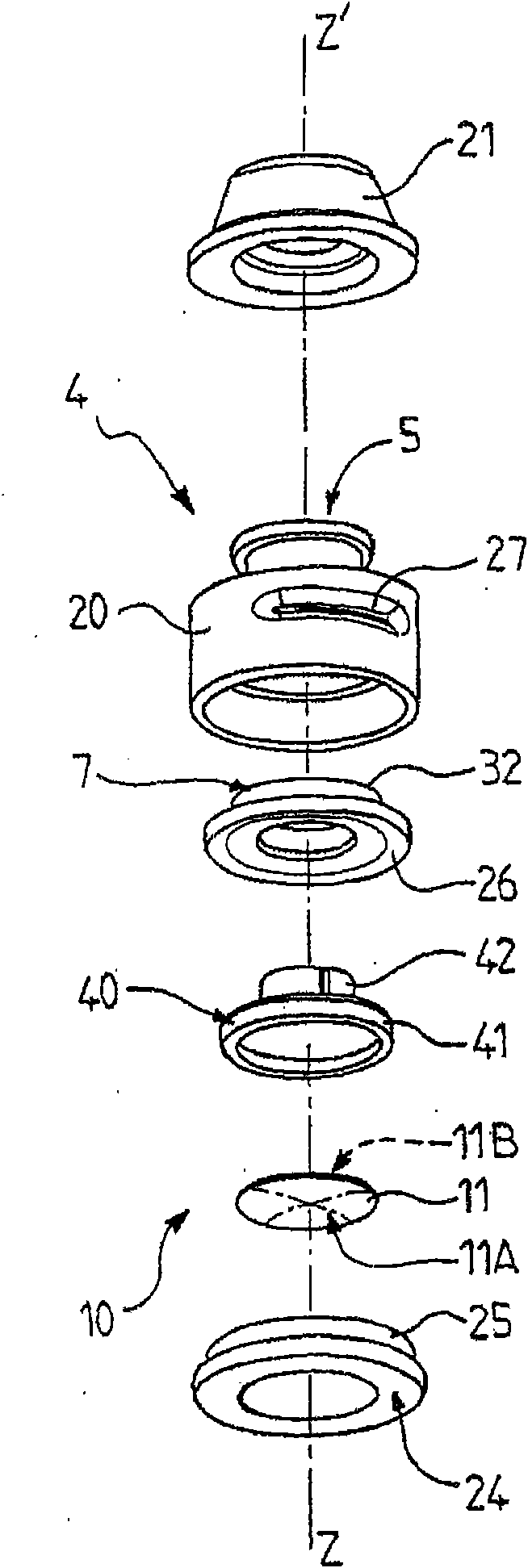

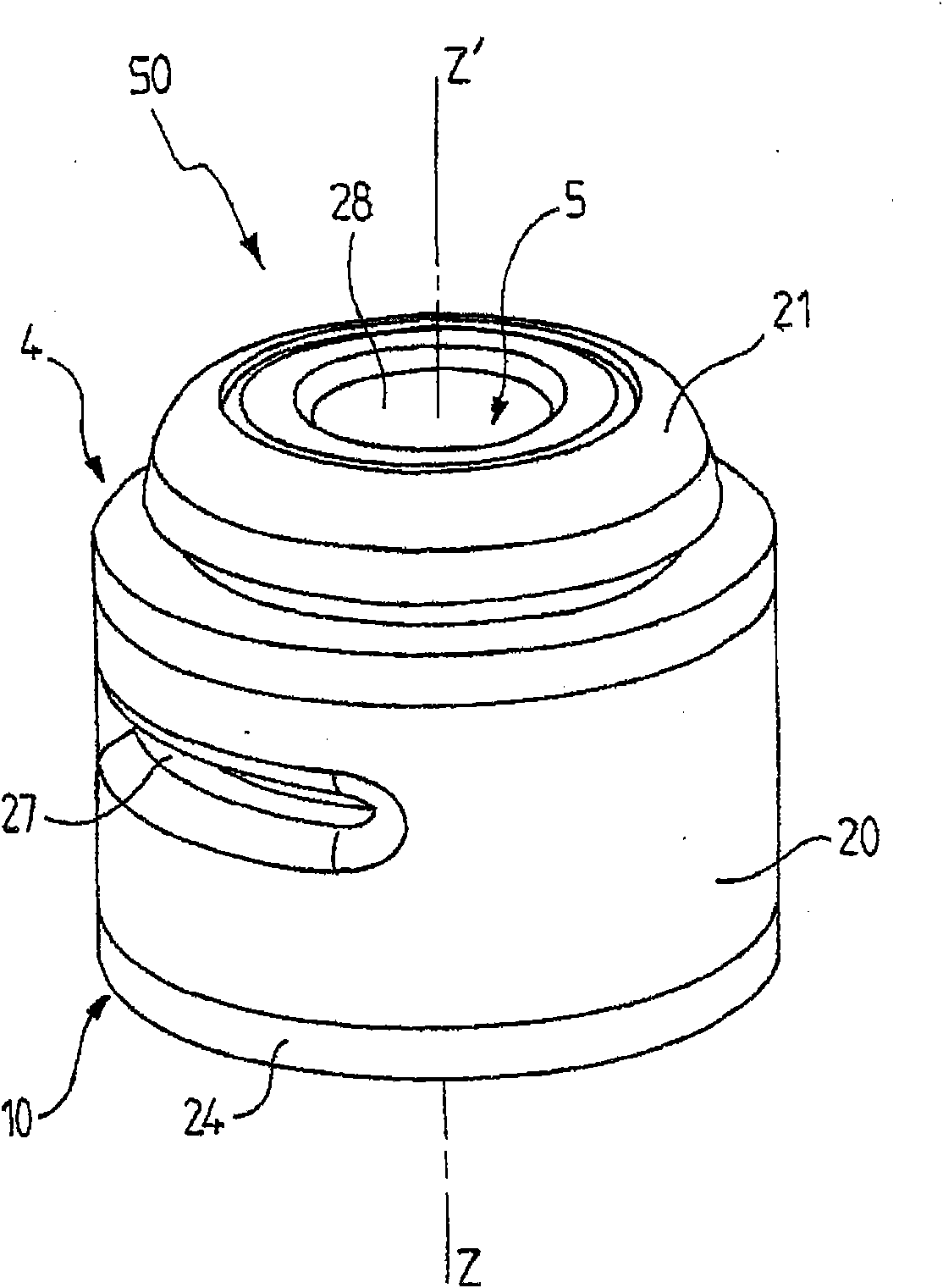

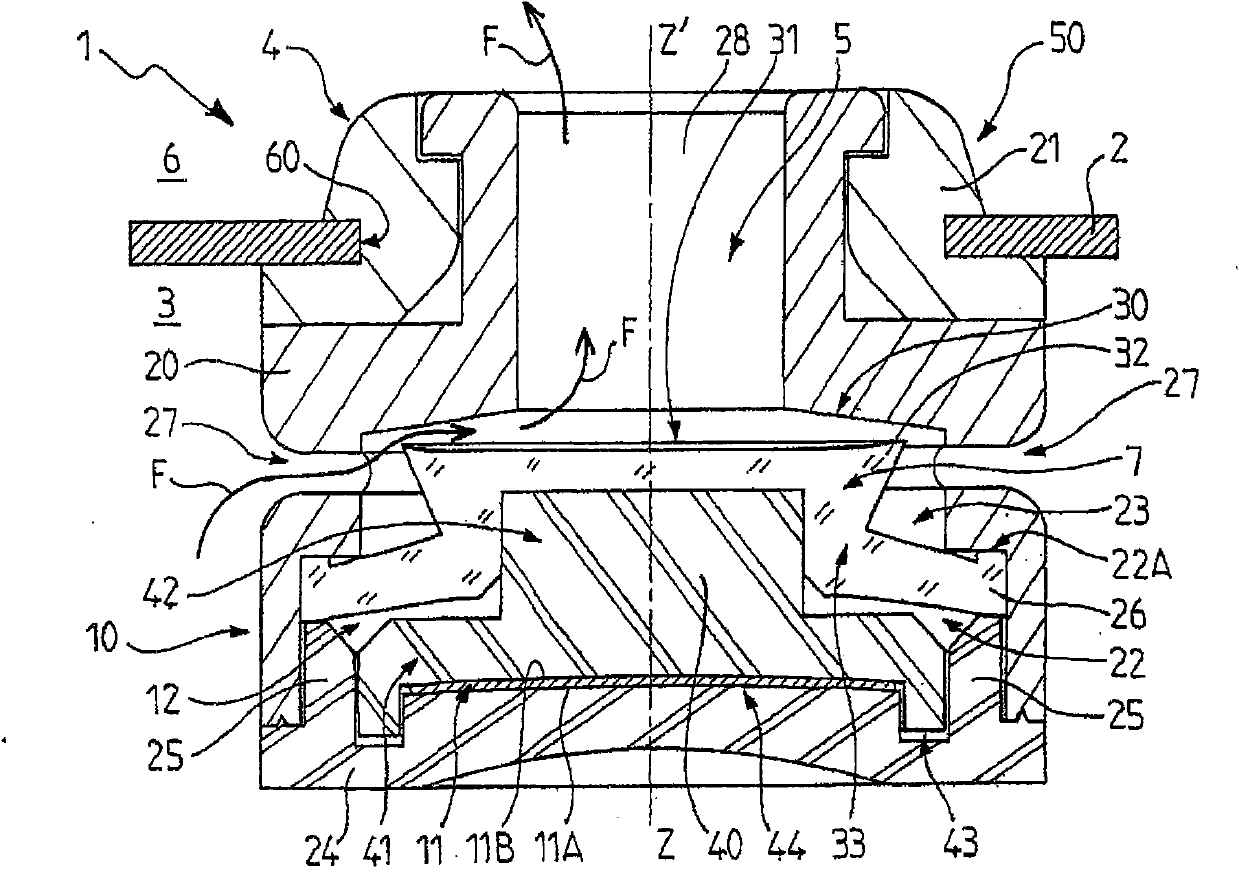

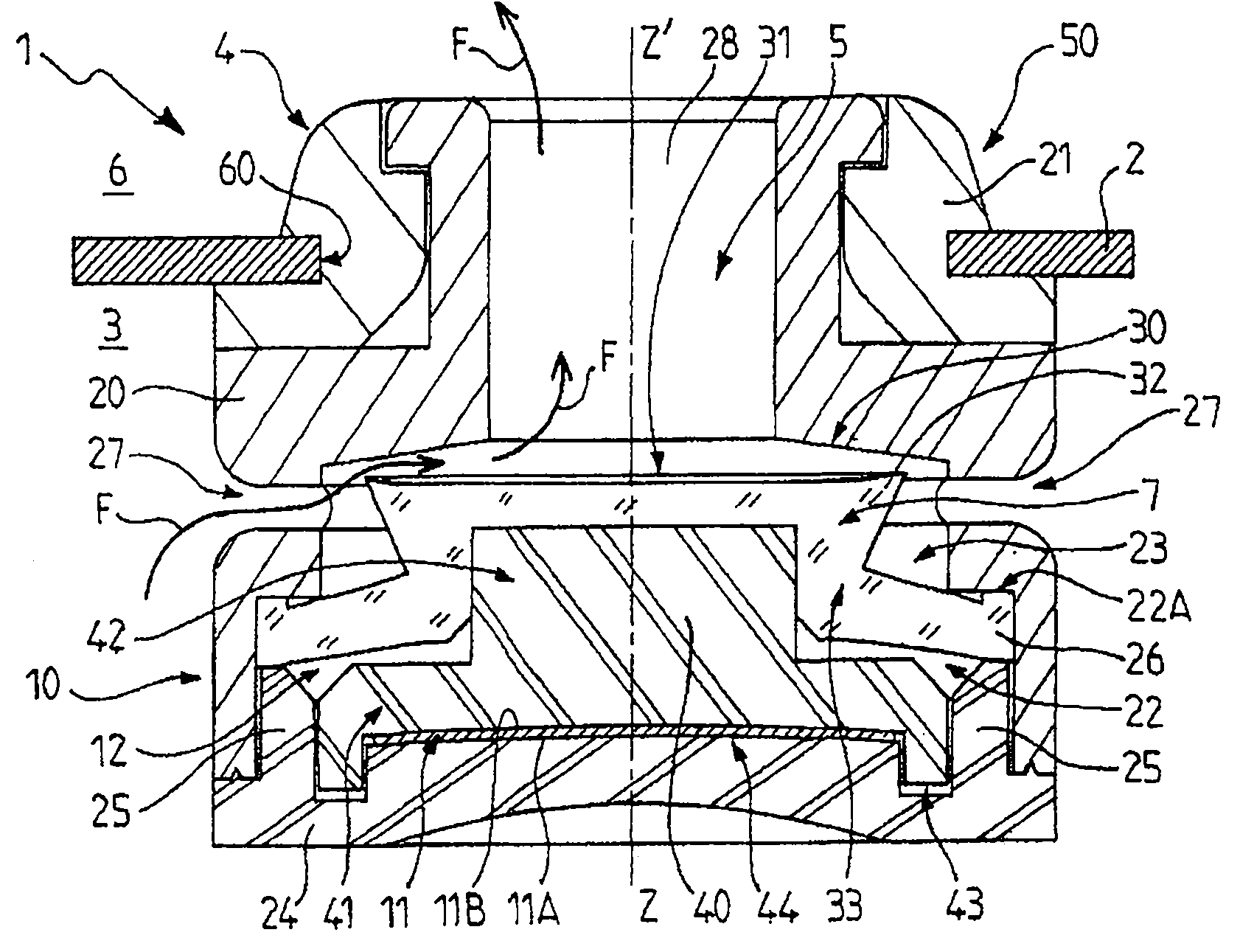

Pressure cooker having packaged discharging temperature controlled switch

The present invention relates to an apparatus (1) for cooking food under pressure. The apparatus has a discharging device (4) capable of expelling air from a housing of the apparatus when the cooking is started, and a control device (10) that is designed to make the discharging device (4) change the structure from opening to closing. The apparatus is characterized in that the control device (10) comprises a solid actuator component (11) that is contained in a basic airtight restricting zone (12), and the restricting zone is suitable for separating the actuator component (11) from an air current (F) incoming from the housing (3).

Owner:SEB SA

Shopping cart with a magnifying glass

InactiveUS8746709B2Improve protectionComfortable appearanceCarriage/perambulator accessoriesVehicle bodiesMagnifying glassEngineering

A magnifying glass that is mounted on the shopping cart can be moved from a protected neutral position into the reading position only when no key is in the coin deposit lock, and the key can be inserted into the lock only after the magnifying glass has been placed into the protected neutral position.

Owner:WIETH FRANZ +1

A built-in prestressed wooden beam

ActiveCN104533014BImprove fire performanceImprove thermal insulation performanceBridge structural detailsGirdersWhole bodyPre stress

Owner:NANJING TECH UNIV

Anti-corrosion treatment method for logs for pet houses

InactiveCN110696128AQuality assuranceGuaranteed uniformityWood treatment detailsWood impregnation detailsCelluloseCopper naphthenate

The invention discloses an anti-corrosion treatment method for logs for pet houses, which is characterized by comprising the following steps: S1, cutting the logs transversely and longitudinally by using a cutting mechanism to ensure that the cut surface of the logs is flat and the logs have a cubic structure to obtain a wood board F1; and S2, calibrating the wood board F1 by using an infrared level meter, and if the surface of the wood board F1 has a large inclination, cutting again by using the cutting mechanism to obtain a wood board F2. According to the invention, a copper naphthenate solution preservative coats the surface of the logs for a plurality of times, so that the permeation uniformity of the preservative is ensured; and then the preservative is injected into the board throughair compression, so that the chemical reaction process of some effective components of the preservative and starch, cellulose and sugar in the wood is completed, the living environment required by bacteria and insects causing wood decay is damaged, the preservative performance in the wood is ensured, and meanwhile, the wood preservative performance can be further improved by matching with a formalin solution.

Owner:福建龙兴九源科技股份有限公司

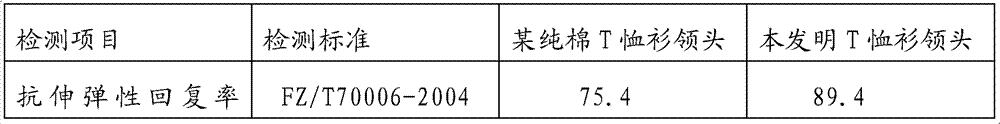

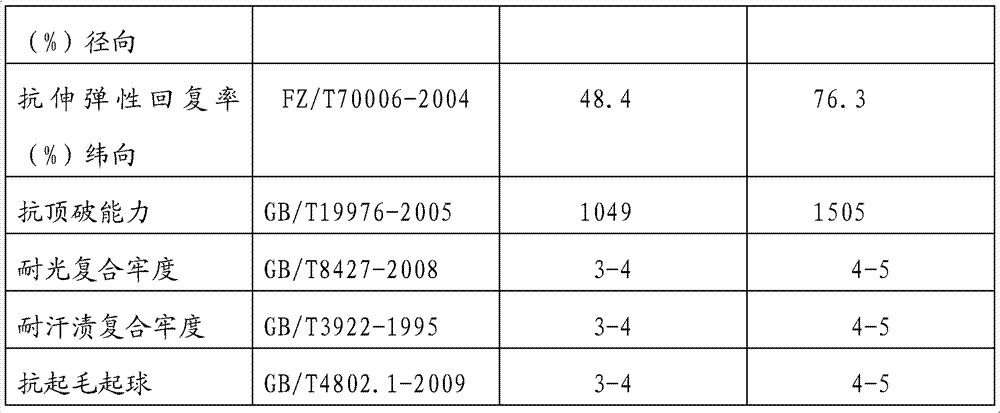

Cotton coated yarn collar and production method thereof

The invention relates to a collar, in particular to a cotton coated yarn collar and a production method thereof. The collar is woven by adopting the following components in percentage by weight: 52 to 56 percent of cotton yarns, 27 to 31 percent of polyester yarns and 15 to 19 percent of polyurethane coated yarns. Compared with the prior art, the invention has the advantages that: the polyester yarns and the polyurethane coated yarns with low cost are adopted for greatly substituting cotton yarns to weave the collar, and the performance of the produced cotton coated yarn collar is even superior to that of a pure cotton collar, so that the production cost of the collar is greatly reduced, the collar is hardwearing and durable, and the market competitiveness of the collar is improved; and proved by detection, the produced collar keeps the original appearance of the pure cotton collar, is close to the skin and comfortable, has thermal insulation property and air permeability, is light, elastic, stiff and smooth, and is not easily deformed or pilled.

Owner:泉州市劲超针织实业有限公司

Prestress embedded steel bar connection splicing wood beam

PendingCN114592649AIncrease stiffnessImprove ductilityRoof improvementGirdersLong spanMechanical engineering

The invention discloses a prestressed embedded steel bar connection spliced wood beam which comprises a plurality of wood beam sections which are connected into a complete wood beam through nodes, and each wood beam section is formed by cutting off a complete giant wood beam according to actual transportation conditions; the joint comprises hardware at the two ends of the wood beam section and an inhaul cable at the bottom of the wood beam. The hardware is implanted into the two ends of the wood beam section through the screws connected with the hardware in a bolted mode, the inhaul cable is buckled in a cable groove in the bottom of the wood beam through a matched cable saddle, and the end of the inhaul cable is anchored to the hardware through a sleeve. And hardware at the end parts of different wood beam sections is connected through field welding. According to the prestressed embedded steel bar connection spliced wood beam disclosed by the invention, the hardware is fixed on the wood beam at the end part in an embedded steel bar screw mode, and the tensile property of the wood beam at a rigid node is improved by utilizing an embedded steel bar connection rift-grain force transfer mode, so that the brittle failure of tensile splitting of a wood tensile area is avoided. And meanwhile, for the outer-layer embedded steel bars under the action of long-term high-strength load, the zippers additionally embedded into the wood beam at the bottom of the beam can play a role in replacement when the zippers fail to work. The method is high in bearing capacity, reliable and stable in system and easy to machine. The method is suitable for the structural fields of large-span buildings, bridges and the like.

Owner:SUZHOU CROWNHOMES TIMBER STRUCTURE TECH CO LTD

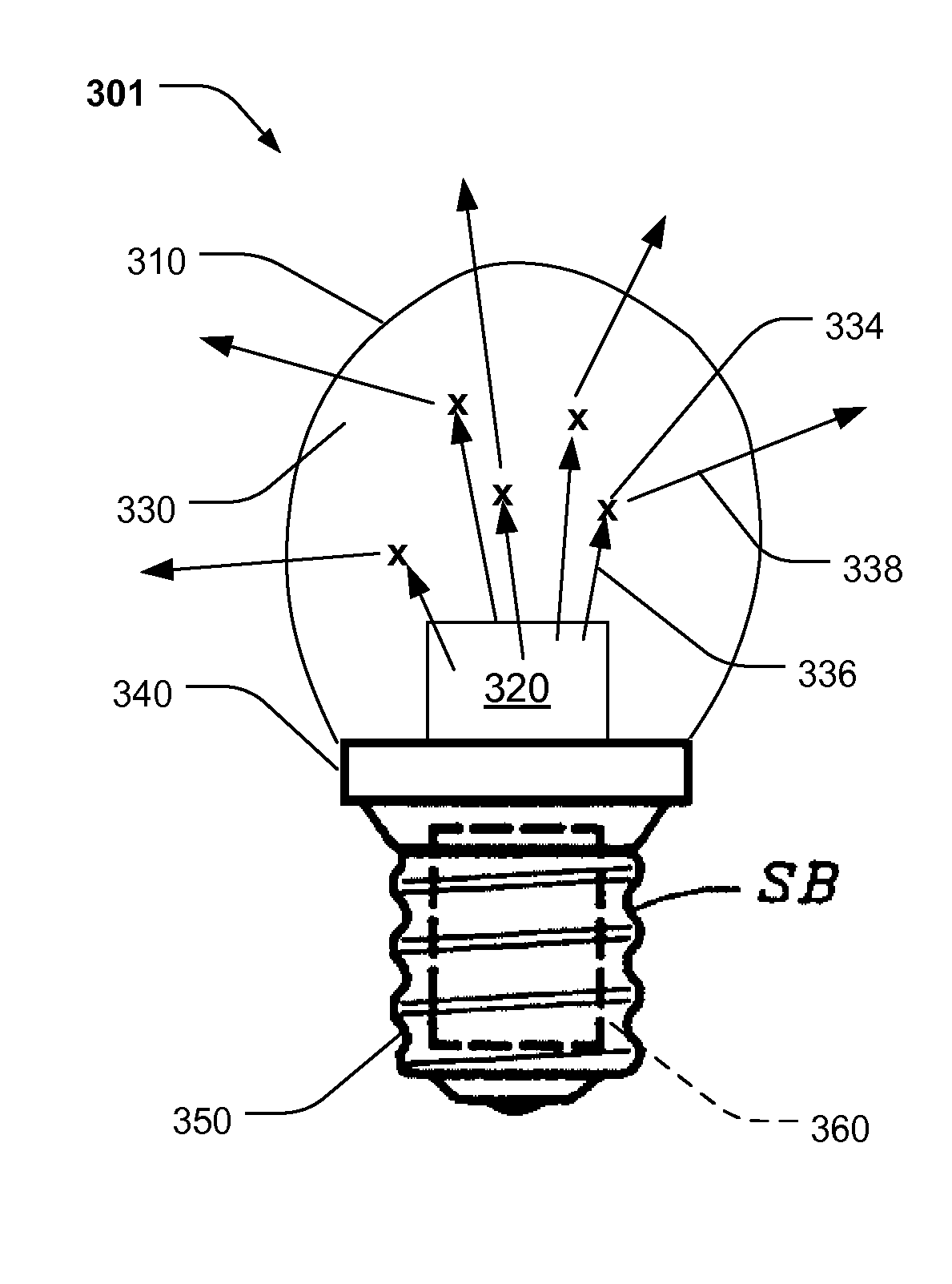

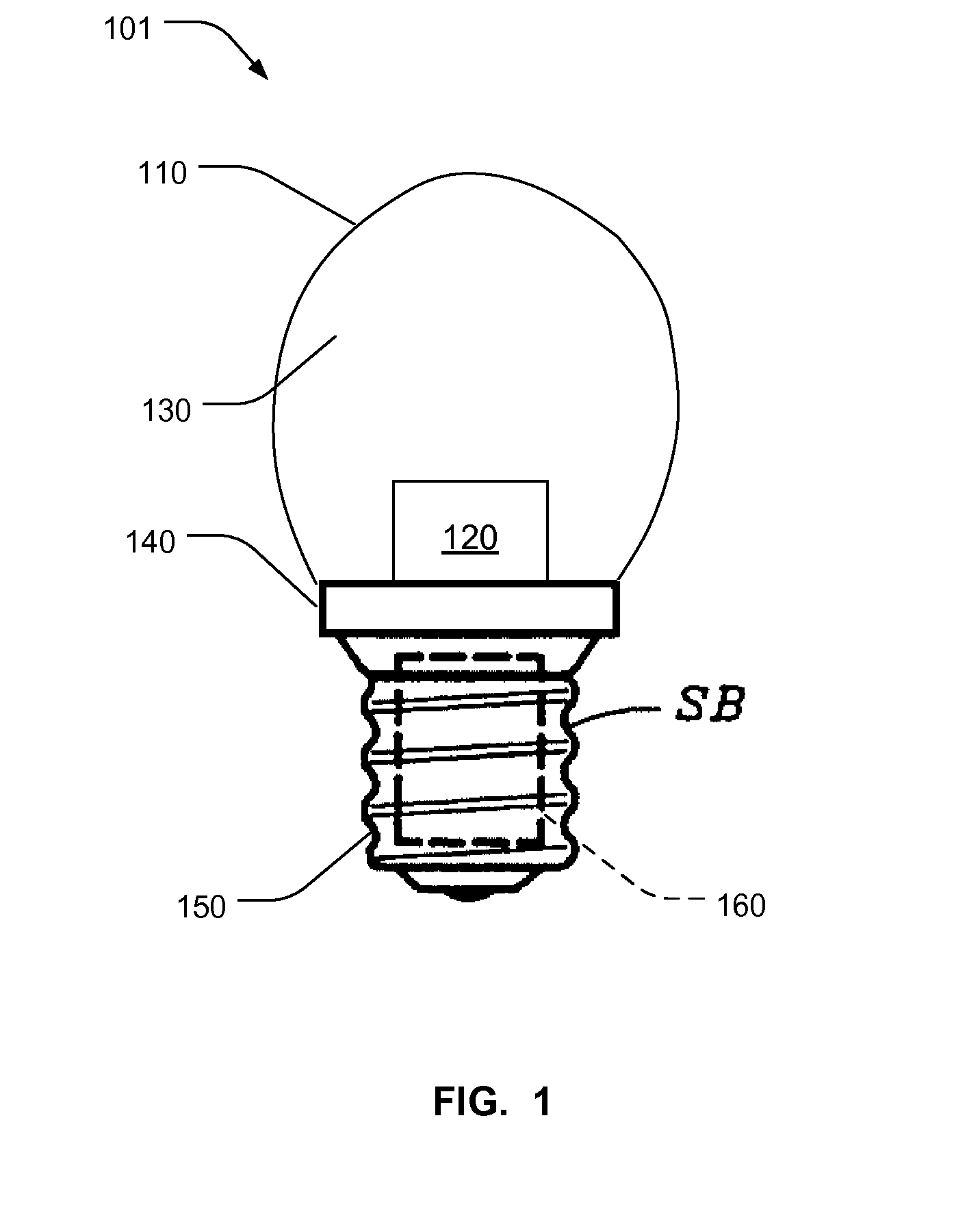

Lighting system using dispersed fluorescence

InactiveUS20140361680A1Disadvantage be reduceLarge light outputDischarge tube luminescnet screensLighting heating/cooling arrangementsLighting systemBright spot

A system for generating light using a blue or ultraviolet light emitter as excitation source for dispersed fluorescent material is disclosed. A light transmissive dispersant, which may colloidally suspend or chemically dissolve a fluorescent material, acts to distribute the fluorescent material over a spatial region. The combination of primary and secondary light emission results in a broader light spectrum than the primary emitter alone would produce. Extending the light transmissive dispersant medium containing fluorescent material over a spatial region spanning beyond point sources will minimize or eliminate bright spots, which might otherwise result from point sources. Use of a liquid dispersant may result in convective cooling of the emission sources.

Owner:Q TECH CO LTD

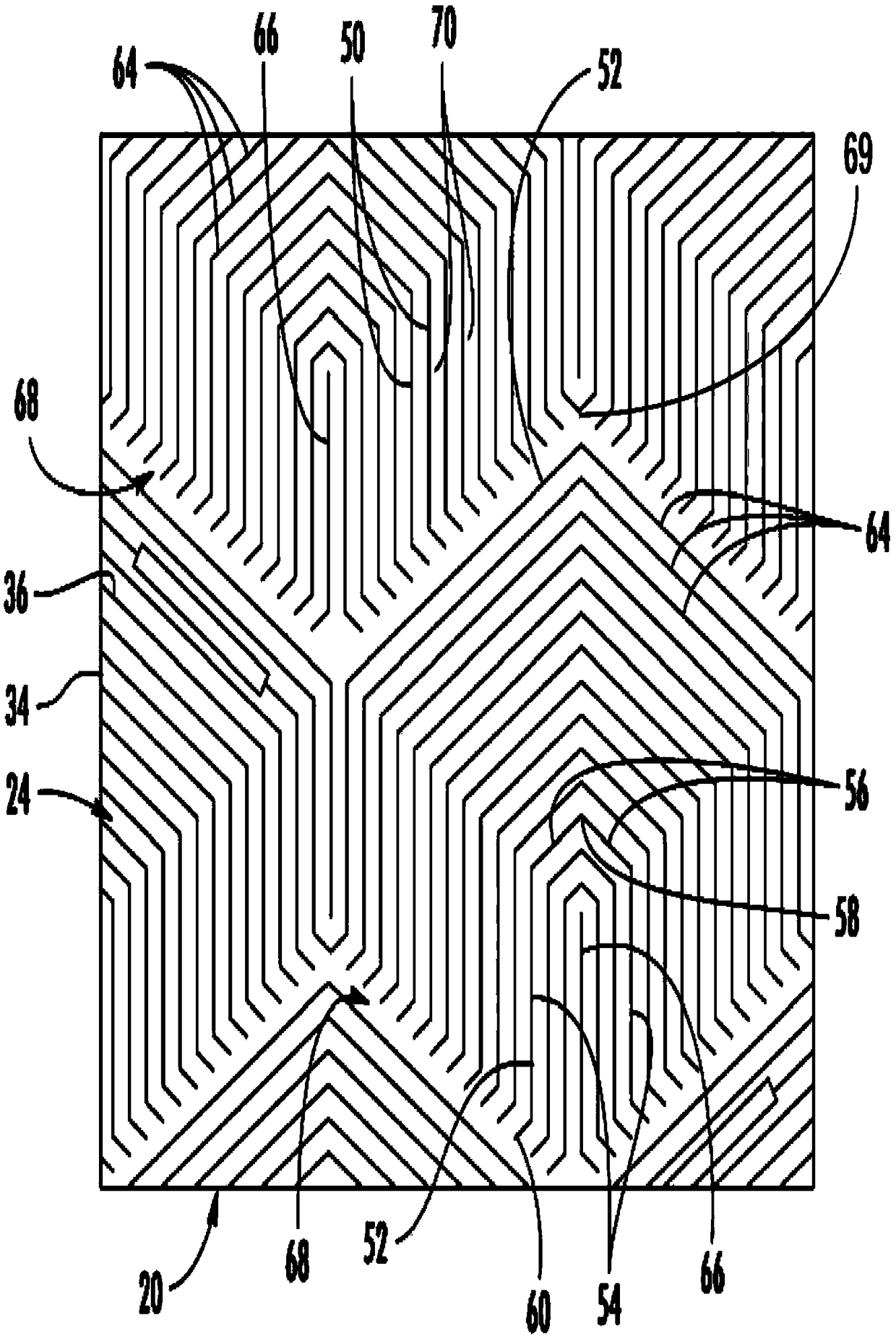

Garment with warmth-keeping layer and manufacturing method thereof

InactiveCN108618212AImprove thermal qualityIncreased durabilityUndergarmentsShirtsPrinting inkNinetieth percentile

A garment article comprises a fabric portion which has an inner side and an outer side limited by the garment article. A ceramic print is provided on the inner side of the fabric portion and comprises, by weight, at least 5% of ceramic and covers at least 10% of the inner side of the fabric portion. A making method of the garment article includes: printing ink containing, by weight, at least 5% ofceramic on a first side of the fabric portion to provide fabric and further includes: combining the fabric with the ceramic print in a garment to enable the first side of the fabric portion to be exposed on the inner side of the garment. The fabric has the ceramic print and covers at least 10% to 90% of the inner side of the fabric portion. The invention provides a garment with excellent heat-insulating quality and retaining high durability, air breathability and moisture wicking quality. The garment provides comfortable appearance and feeling to a wearer.

Owner:RUGAO LANTU KNITTING CLOTHING CO LTD

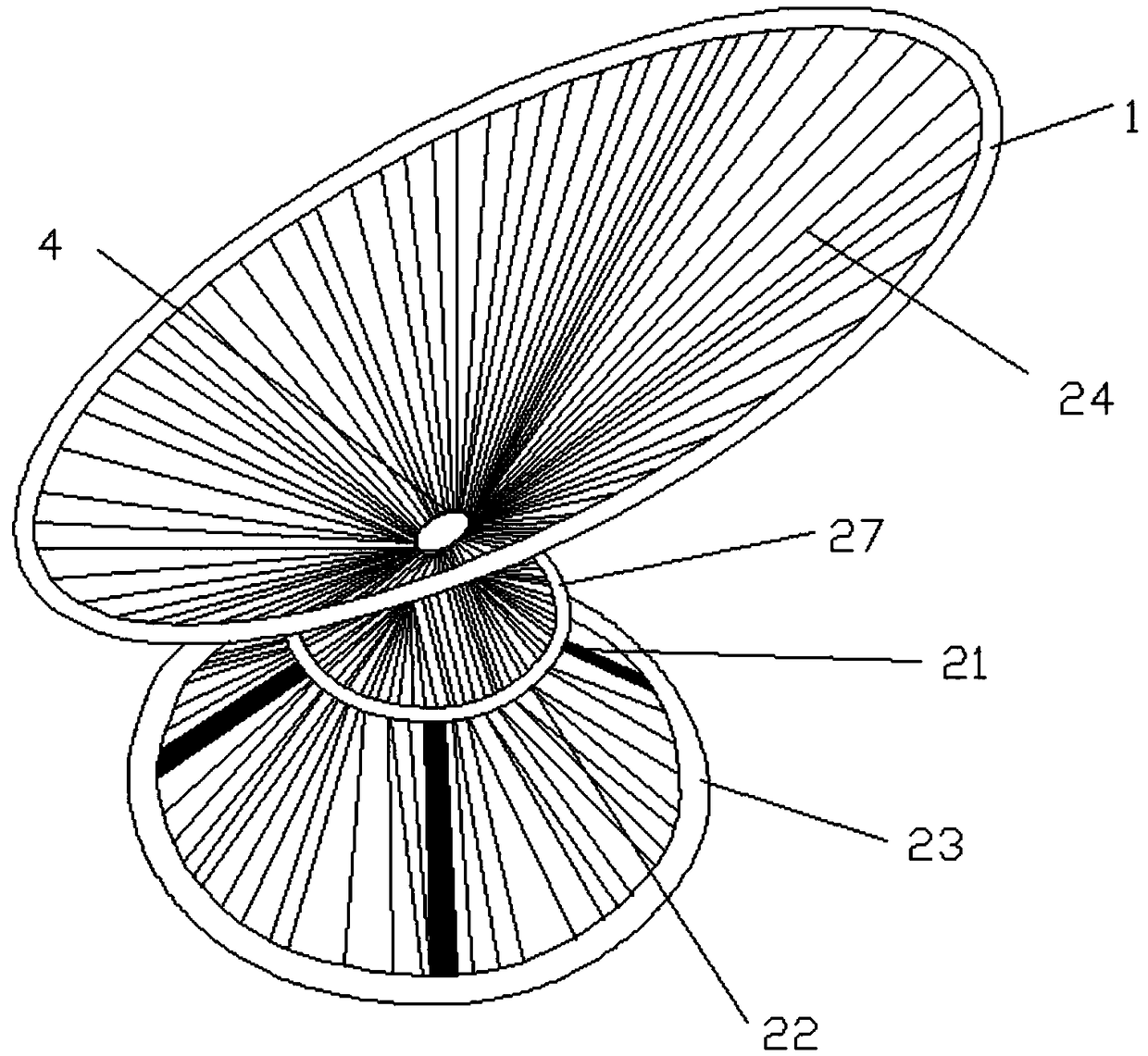

Goose egg-shaped multifunctional leisure chair

InactiveCN108713916ABeautiful appearanceComfortable appearanceStoolsAdjustable chairsLife qualityFixed frame

The invention relates to the technical field of leisure chairs and particularly relates to a goose egg-shaped multifunctional leisure chair. The goose egg-shaped multifunctional leisure chair comprises a support round frame and a sleeve, wherein a support frame is welded to the side wall of the support round frame, a fixing frame is welded to one end, far from the support round frame, of the support frame, a column body is vertically and downwards welded to the bottom of the fixing frame, and a fixing block is welded to one end, far from the fixing frame, of the column body; and a rotating mechanism is arranged on the inner wall of the sleeve, a through hole I is formed in the bottom of the sleeve, a screw I is in threaded connection to one end of the rotating mechanism in the sleeve, theinner wall of a top port of the rotating mechanism is sleeved with a bearing, a fixing column is fixedly connected to one end, far from the bearing, of the connecting column, the outer wall of the fixing column is sleeved with a triangular cushion block, and a screw II sequentially connected with a cushion block I and an elastic piece in a penetration manner. The goose egg-shaped multifunctional leisure chair has the beneficial effects that the appearance is attractive and comfortable, so that the art sense is added for the life, and the life quality is improved; and the leisure chair can be rotated by 360 degrees and can swing front and back, so that the experience level is increased, and the comfort level is increased.

Owner:易明钱

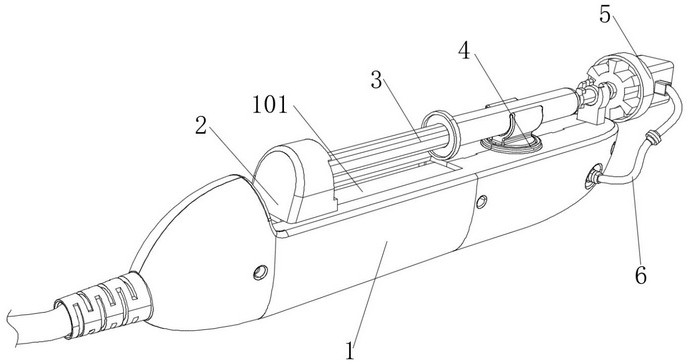

Injection device capable of injecting liquid

InactiveCN114848973AElasticWith electrical connectionAutomatic syringesMedical devicesMedicineMechanical engineering

The invention relates to the technical field of skin beautifying equipment, in particular to an injection device capable of injecting liquid, which comprises a shell, a hydro-optical needle is arranged at the top end of the shell, an automatic injection mechanism is arranged in the shell, and the top end of the automatic injection mechanism penetrates through the shell and is connected with one end of the hydro-optical needle; a clamping identification mechanism is arranged between the hydro-optical needle and the shell; the clamping recognition mechanism in the device can automatically recognize the specification of the needle cylinder, the link of manually inputting the specification of the needle cylinder is avoided, the risk of manual input errors is avoided, the safety of an injection person is ensured, meanwhile, medical accidents are reduced, time and labor are saved, and compared with an air pipe directly arranged outside the shell, the device is more convenient to use. The probability that a worker extrudes the air pipe can be reduced, normal circulation of the air pipe is guaranteed, the situation that when a traditional air pipe needs to change the airflow direction, the air pipe is bent by 90 degrees, and an air channel is easily blocked is avoided, and blocking is effectively reduced.

Owner:深圳市普朗医疗科技发展有限公司

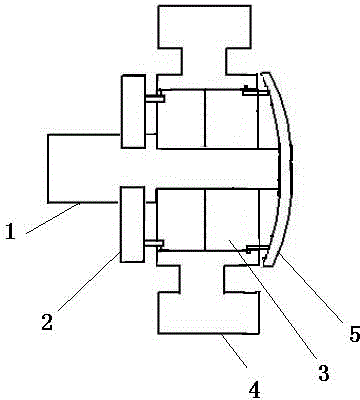

Pressure cooker having packaged discharging temperature controlled switch

#CMT# # / CMT# The appliance has a lid fixed on a vessel to define a sealed enclosure to contain food. A purging unit (4) has an escape opening (5) connected to an interior of the enclosure to an exterior of the appliance. A control unit (10) passes the purging unit from an opening configuration to a closing configuration when a temperature or pressure in the enclosure rises beyond predetermined triggering thresholds. The control unit has a secure activation unit (11) placed in a sealed confinement zone (12) to isolate the activation unit from a gas flow (F) coming from the enclosure. #CMT# : # / CMT# The activation unit is formed by a bimetal element. #CMT#USE : # / CMT# Pressurized food cooking appliance i.e. domestic pressure-cooker. #CMT#ADVANTAGE : # / CMT# The appliance is simple and compact in structure so as to limit the manufacturing cost of the appliance and to improve the aesthetic appearance of the appliance, so that the appliance is easy to maintain. The activation unit is encapsulated in the confinement zone which is sufficiently sealed to separate the activation unit from the gas flow contained in the enclosure and permits the activation unit to escape from the gas flow primarily containing air or water vapor, so that the activation unit is protected from the physicochemical aggressions of the gas flow. The design of the appliance protects the control unit from corrosion, clogging or scaling, thus limiting the risks of mechanical default of the control unit such as triggering threshold or course of moving parts. The purging unit purges the air effectively and accelerates the supply of the air at operating temperature and operating pressure and the integrity and the operation of the purging unit and the control unit to each other is durably preserved, so that robustness of the purging unit and the control unit is improved, thus guaranteeing performance reliability, robustness and longevity of the appliance. The separation of the activation unit and the gas flow allows avoiding any pollution of the cooking atmosphere and food by the units constitutive of the control unit, thus durably guaranteeing the food quality of the appliance. The design of the appliance avoids complexity of manufacture and implementation of the storage and transport units of the fluid such that risk of escape or bursting and failure of the control units related to the fluid exposure at high temperatures and pressures is avoided. #CMT#DESCRIPTION OF DRAWINGS : # / CMT# The drawing shows a longitudinal sectional view of a purging module including a purging unit and a control unit, with the purging unit in an opening configuration. F : Gas flow 4 : Purging unit 5 : Escape opening 10 : Control unit 11 : Secure activation unit 12 : Sealed confinement zone.

Owner:SEB SA

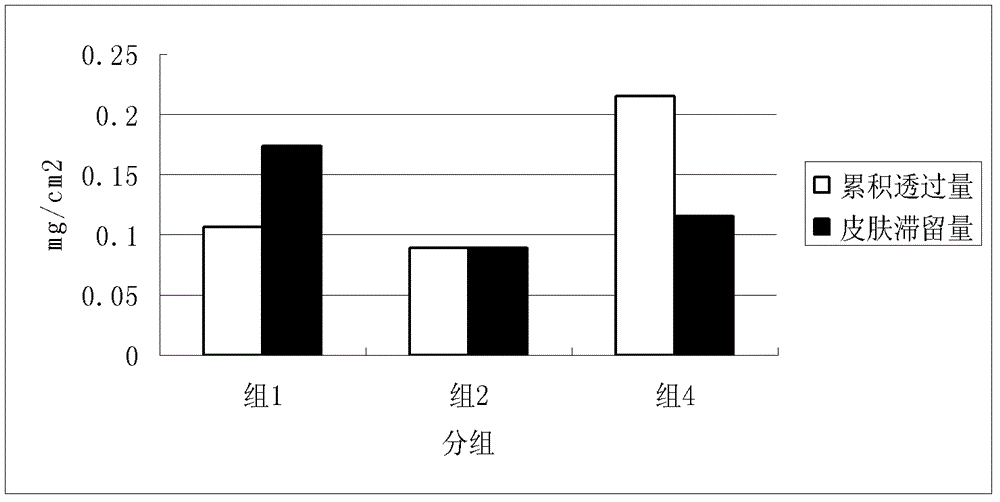

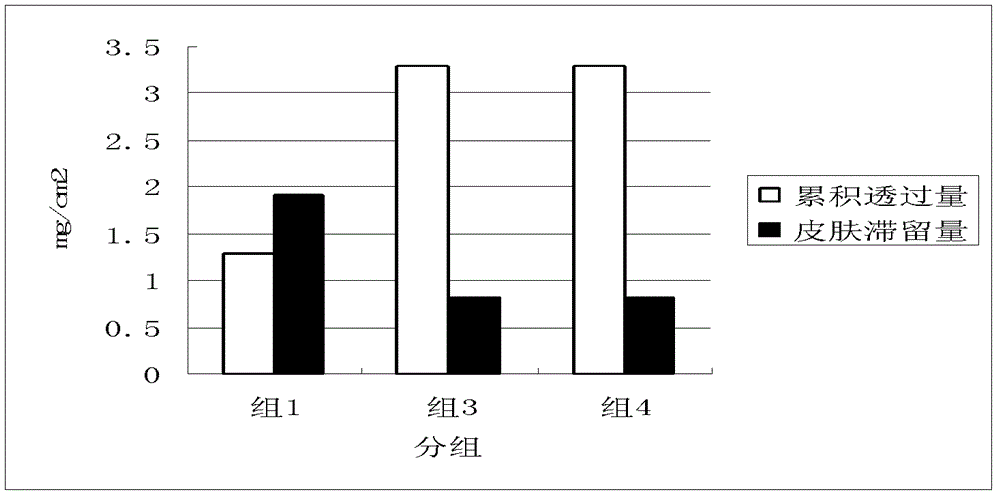

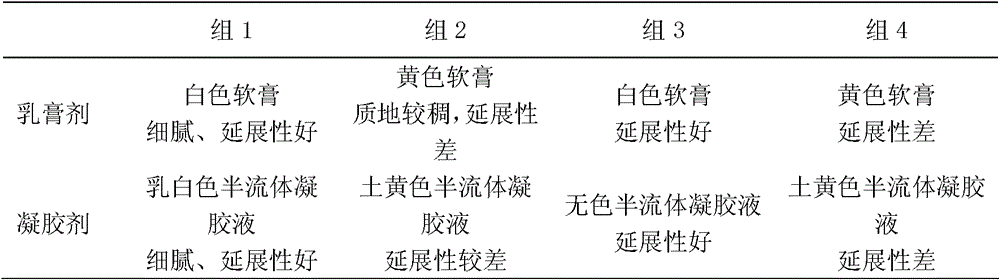

Composite cyclodextrin clathrate of licorice flavones and ferulic acid and preparation method and applications thereof

ActiveCN102274145BImprove stabilityGood whitening effectCosmetic preparationsToilet preparationsAdditive ingredientCyclodextrin

Owner:GUANGDONG SOUTHERN JIELING TECH IND

Projector mount

InactiveCN101226323BEasy to installComfortable appearanceProjectorsStands/trestlesSupporting systemProjection screen

A low profile projector mount for media projectors, enabling images of a media projector to be sufficiently aligned with a projection screen upon which the images are to be displayed. The alignment of the low profile projector mount is achieved through pitch, roll, and / or yaw adjustment mechanisms incorporated into the low profile projector mount. The low profile projector mount can be flush mounted to a ceiling or attached to an extension column or other intermediary support system. A quick-release system allows a projector attached to the low profile, projector mount to be removed without disturbing the low profile, projector mount. In addition, retractable members for effectuating the pitch, roll, and / or yaw adjustments are utilized.

Owner:PEERLESS INDS

Waterproof wheel of floor washer

The invention provides a waterproof wheel of a floor washer. The waterproof wheel comprises a wheel, a bearing, a shaft core and an outer sealing cover which is arranged on the outer side of the bearing and fixed with the shaft core. The inner side of the bearing is provided with an inner sealing cover which is sleeved on the periphery of the shaft core. The shaft core is provided with an inner barrier and a groove, the inner sealing cover is covered on the outer periphery of the groove, the inner barrier is placed between the inner sealing cover and the bearing, so that the shaft core and the inner sealing cover are combined perfectly, and outside water vapor is prevented form entering into the bearing. Meanwhile, the inner sealing cover and the outer sealing cover are directly embedded into a bearing hole through a convex ring which is made of polyurethane, so that embedding of the inner sealing cover and the outer sealing cover and the wheel is very firm, the inner sealing cover and the outer sealing cover can be easy to mount, not easy to age and abrade, and accordingly the service life of the waterproof wheel is prolonged.

Owner:安徽誉林新材料科技有限公司

Method for producing a structured microfilament nonwoven

InactiveCN107849765AExcellent mechanical propertiesSatisfied with the use characteristicsOrnamental textile articlesBed linenNonwoven fabricMaterials science

Method for producing a structured microfilament nonwoven, in which microfilaments and / or composite filaments that are able to be split into microfilaments are spun to form at least one fibre layer, drafted and laid to form a nonwoven; the nonwoven is thermally preconsolidated; the thermally preconsolidated nonwoven is treated with a pressurized medium in order to at least partially break up the thermal preconsolidation; the nonwoven resting on a structuring surface is subjected again to a pressurized medium, whereby a structured microfilament nonwoven is obtained.

Owner:CARL FREUDENBERG KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com