Pressure cooker having packaged discharging temperature controlled switch

A technology of pressure and discharge devices, applied in pressure cookers, household utensils, kitchen utensils, etc., can solve problems such as mechanism failure, complicated manufacturing process, and shortened life span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

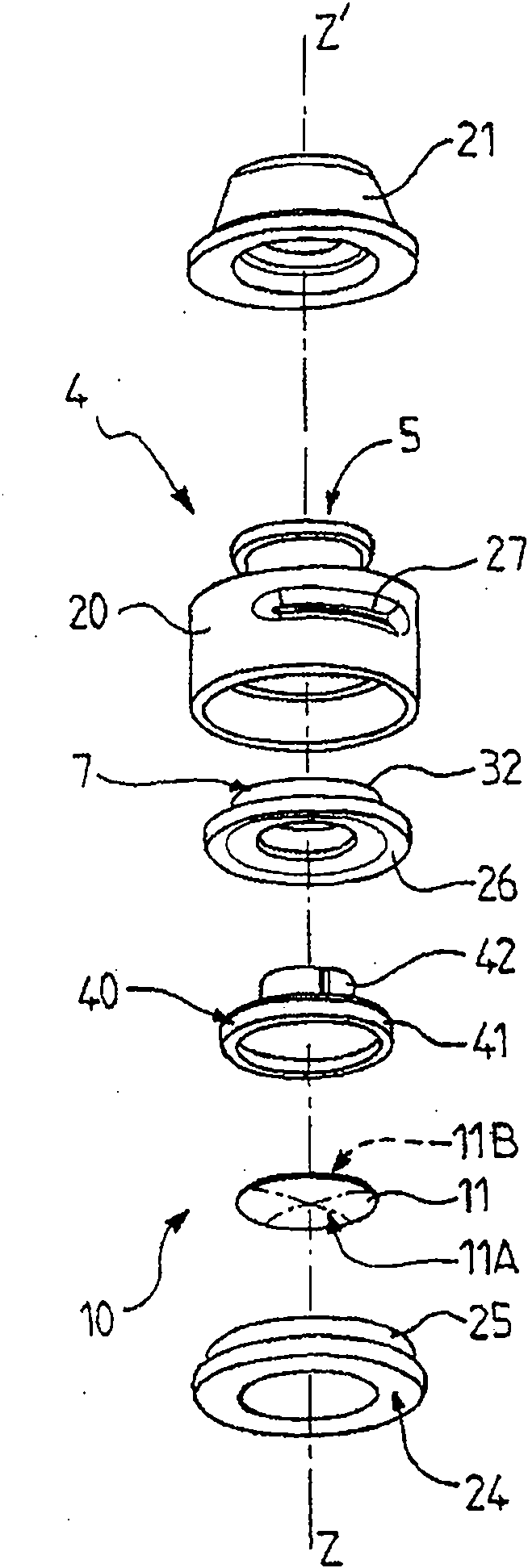

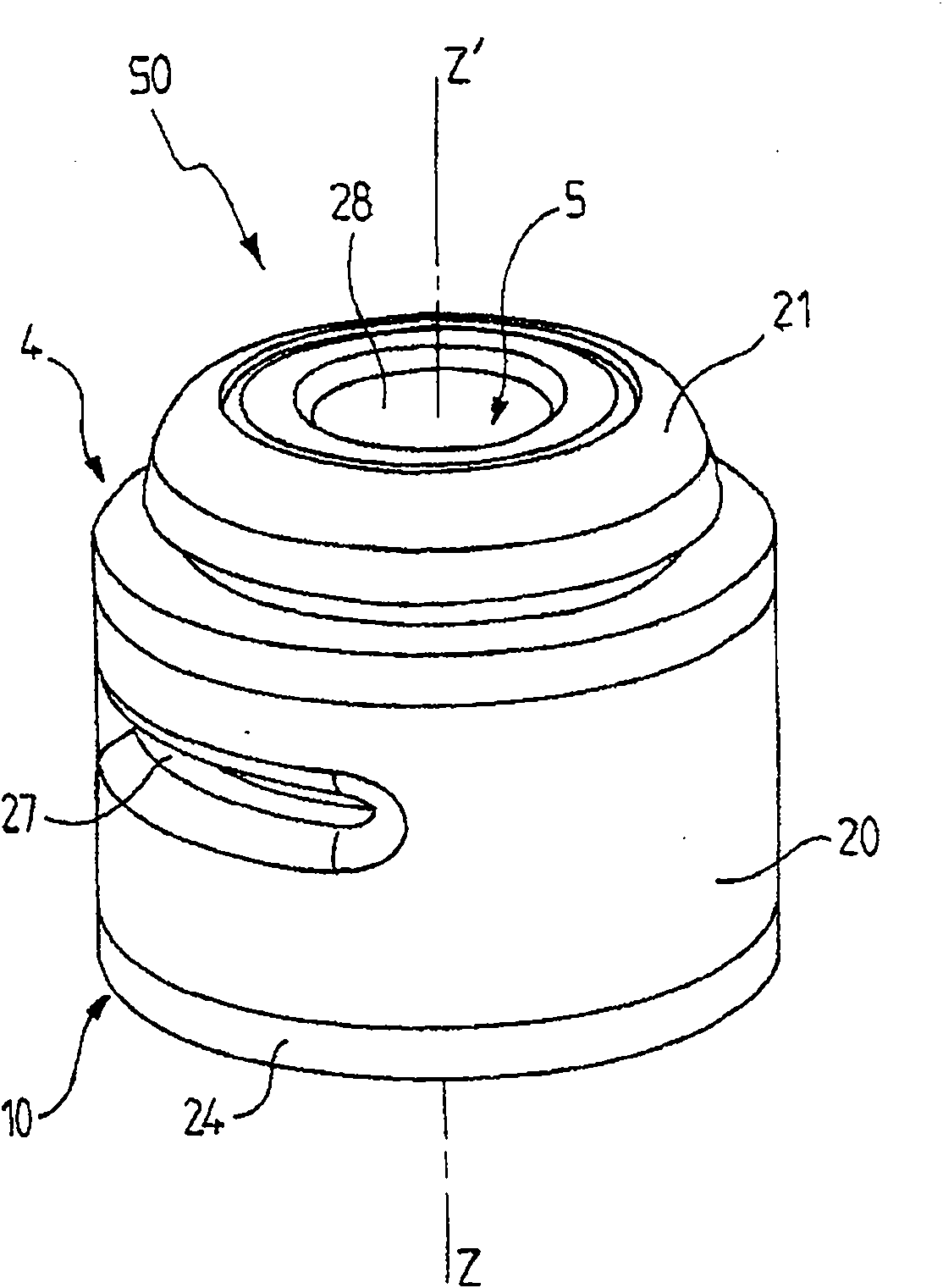

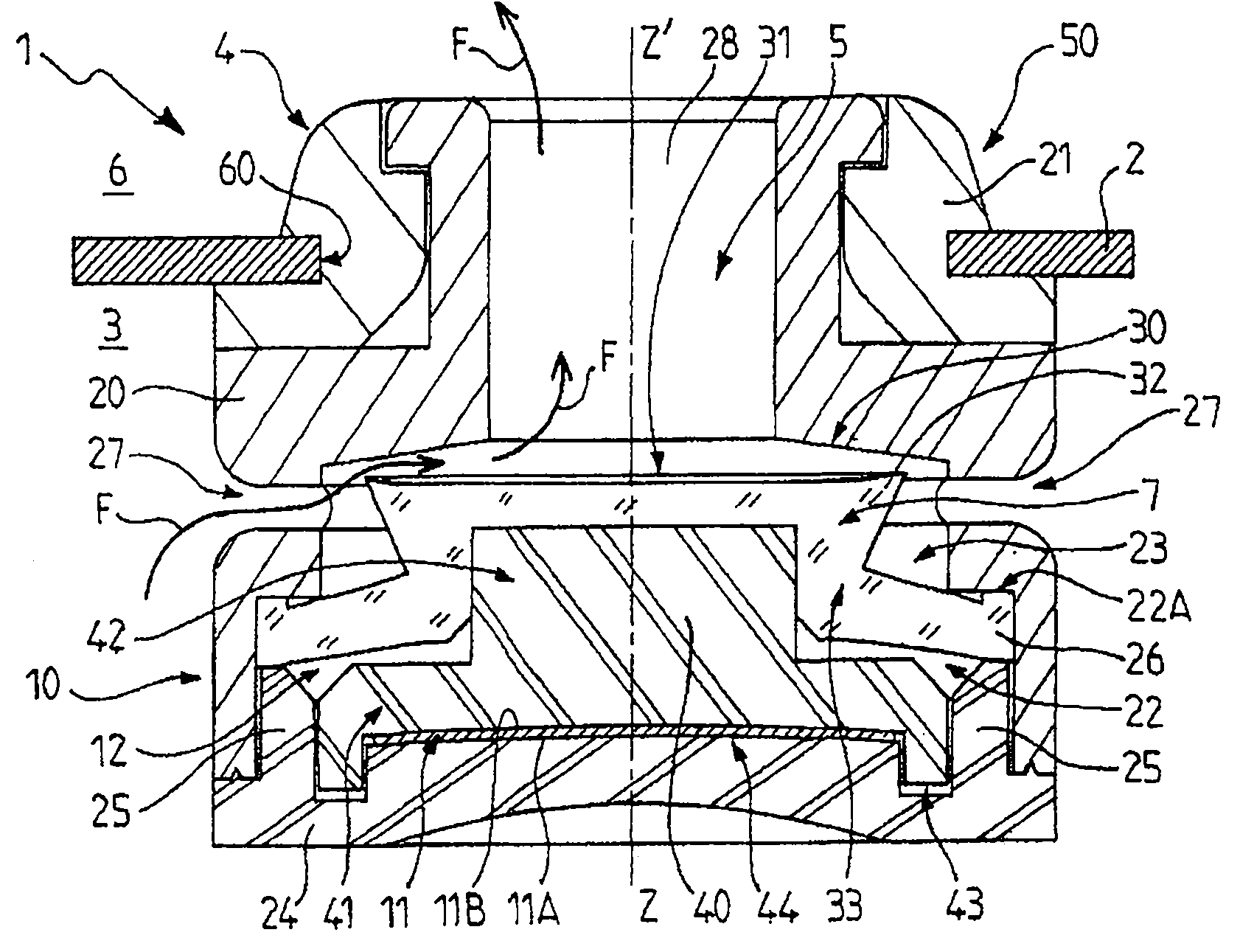

[0028] The invention relates to an appliance 1 of the pressure cooker type for cooking food under pressure, designed to cook food in a medium consisting of steam maintained at a pressure and temperature higher than the ambient atmospheric pressure and temperature.

[0029] According to the invention, the cooking appliance 1 comprises a container (not shown) and a lid 2 designed to be fastened on said container so as to define a casing 3 which is substantially airtight and intended to contain food.

[0030] For this purpose, said cover 2 may be provided with locking means of the type of clips, pliers, bayonets, etc. or any other equivalent system known to those skilled in the art.

[0031] The lid 2 may also be provided with one or more peripheral sealing gaskets for enabling it to fit in a tight manner on the container.

[0032] The cooking appliance 1 according to the invention may also comprise one or more regulators and safety systems for keeping the pressure prevailing ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com