A built-in prestressed wooden beam

A prestressed, built-in technology, applied in the direction of joists, girders, trusses, etc., can solve problems such as poor structural appearance, structural damage, weak fire resistance, etc., and achieve high bearing capacity, light weight, and improved ductility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

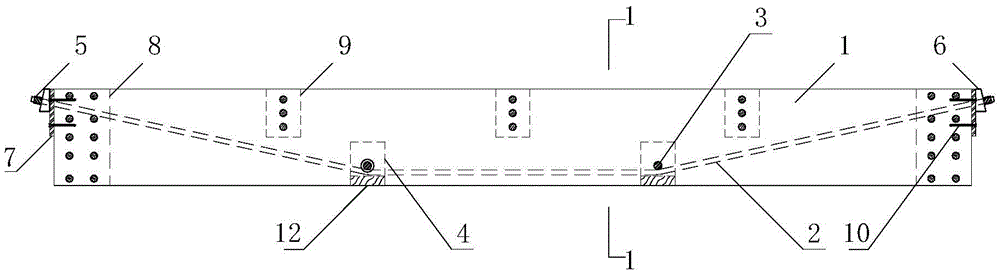

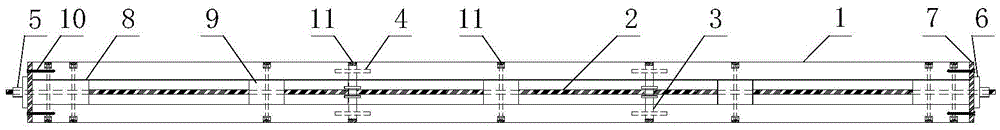

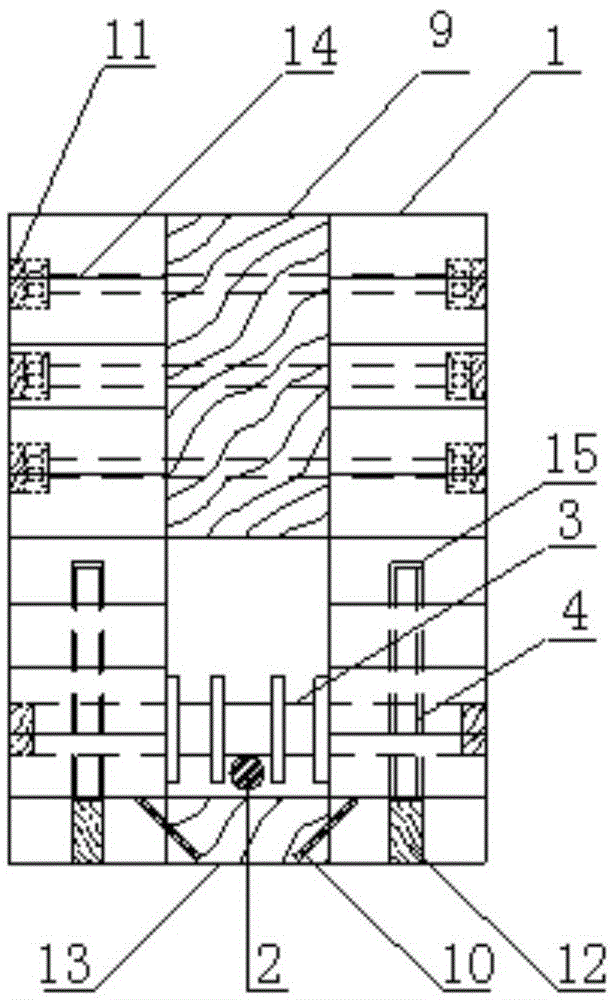

[0041] like Figure 1-13 Shown: a built-in prestressed wooden beam, including a wooden beam 1, a prestressed tendon 2, a steering device and an anchoring device;

[0042] The wooden beam 1 is a double beam, and the spacer 9 between the beams, the spacer 8 at the anchoring end and the bolt 14 are used to connect the two parallel beams into a whole, and the bolt 14 is provided with a log plug 11;

[0043] The prestressed tendons 2 are arranged in the middle gap of the double-spanning beam, and one or more are arranged. Part of it is fixed in the middle of the double beam through the steering device;

[0044] Described anchoring device comprises anchor tool 5, steel pad 6 and anchor backing plate 7, and described anchor backing plate 7 is connected with wooden beam 1, and wooden beam junction is provided with reinforcing self-tapping screw 10 or planting bar, and described anchor The backing plate 7 is provided with a steel pad 6, and the steel pad 6 is provided with an anchor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com