Two-layer solid wood composite floorboard and manufacturing method thereof

A solid wood composite floor and surface board technology, applied in the field of wood processing, can solve the problems that the strength does not meet the requirements, the product is prone to warping, and the cost of raw materials is high, and achieves the advantages of beautiful appearance, reduced coating amount, and reduced formaldehyde emission. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

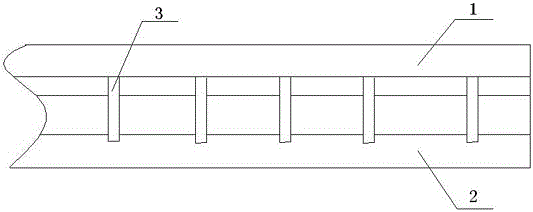

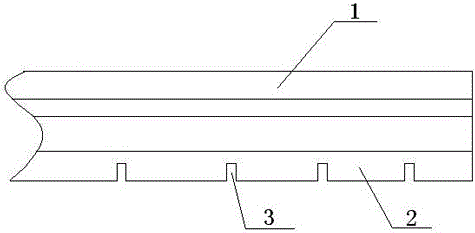

[0023] Example 1. (1) Panel processing: use logs to process boards and squares according to the specifications required by the floor. The panels and squares are processed into panels 1 with a length of 3000 mm, a width of 300 mm, and a thickness of 6 mm. Dry to a pass rate of 30%, dry in a kiln for 15 days, moisture content 5.5%, and balance health for 80 hours;

[0024] (2) Substrate processing: use logs to process substrate 2 boards with a length of 3000 mm, a width of 300 mm, and a thickness of 20 mm, pre-dried to a pass rate of 30%, and dried in a kiln for 15 days, with a pass rate of 7%. , 80 hours of balanced health preservation;

[0025] (3) Grooving: sanding the solid wood substrate, and groove 3, wherein the width of the groove is 2.0 mm, the distance between adjacent grooves is 60 mm, and the depth of the groove is 15 mm;

[0026] (4) Hot pressing: Apply glue to the back of the prepared panel, the amount of glue applied is 200g / ㎡, place the panel and the substrate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com