Mountable and replaceable type low yield point compound energy dissipation multiple-seam type coupling beam system

A low-yield point, low-yield point steel technology is applied in the field of shock absorption control and prefabricated structures of structural engineering, which can solve the problems of insufficient seismic capacity and reduce the damage degree of the main structure, so as to achieve high ductility damage, reduce Main body destruction, clear effect of energy consumption mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

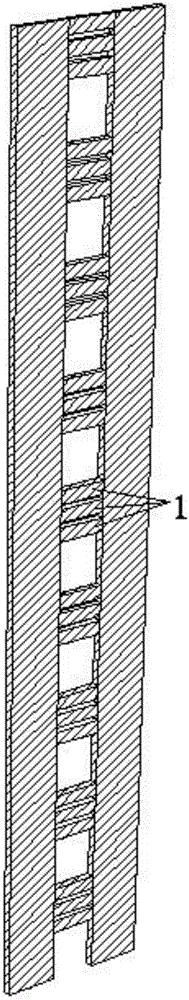

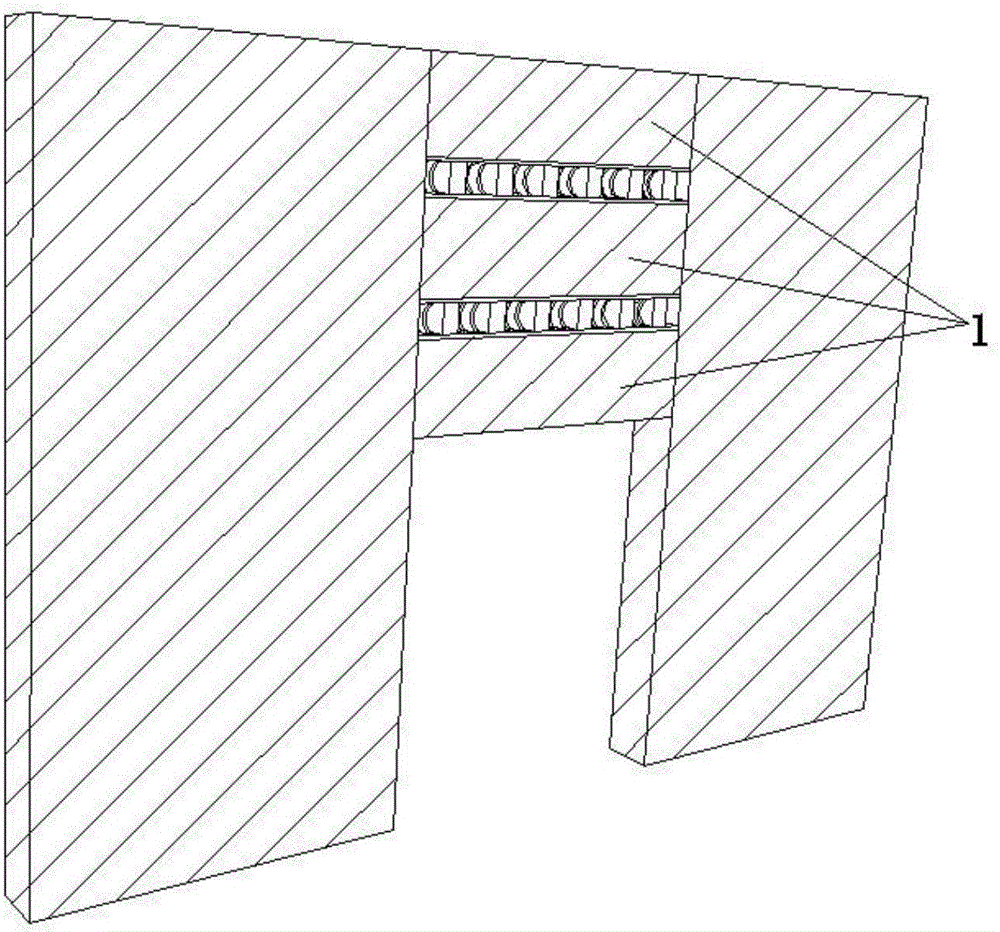

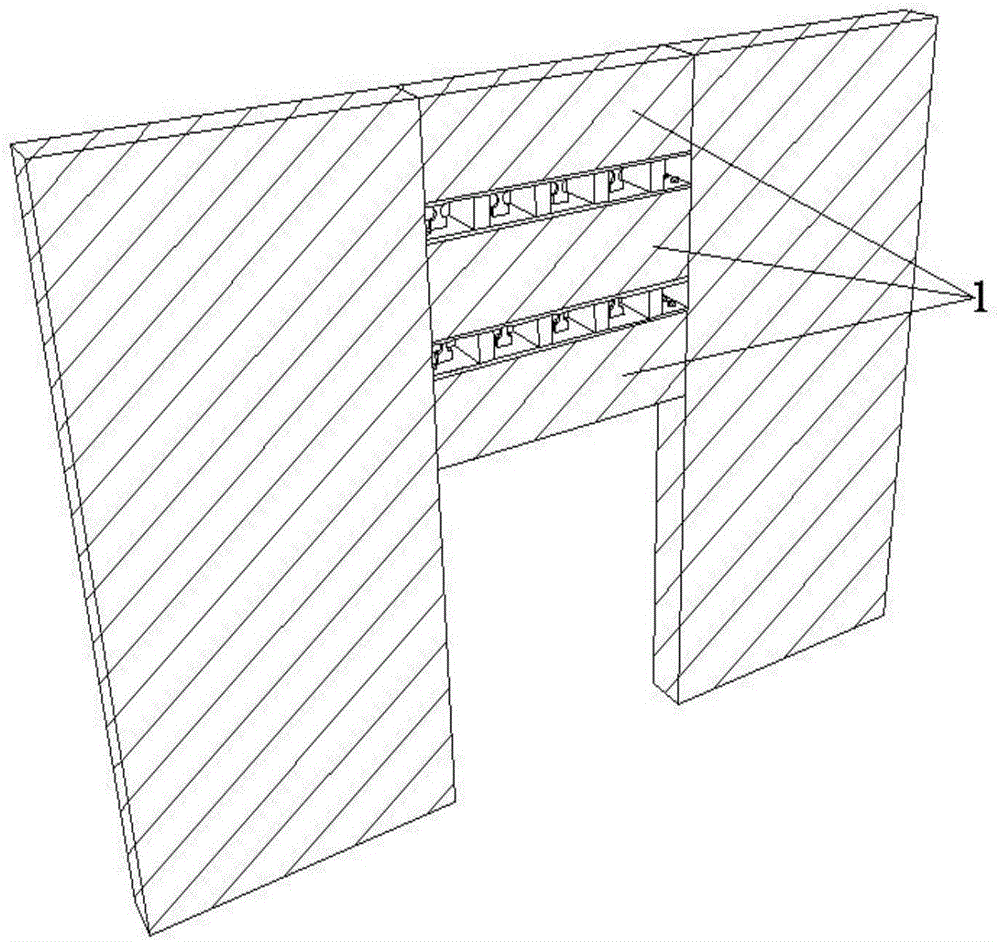

[0037] as attached figure 2 , 3As shown, it is an embodiment of the present invention's assembleable and replaceable low-yield point composite energy-dissipating multi-slit coupling beam system in a reinforced concrete shear wall structure, including: reinforced concrete multi-slit coupling beam 1, composite energy-consuming The upper cover plate 2 of the energy device, the lower cover plate 3 of the composite energy dissipation device, the low yield point steel 4, the energy dissipation lead block 5, the environmental protection paint 6, the bolt 7 and the bolt hole 8; The upper cover plate 2 of the energy-dissipating device and the lower cover plate 3 of the composite energy-dissipating device are welded, the energy-dissipating lead block 5 is connected with the upper cover plate 2 of the composite energy-dissipating device and the lower c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com