Muffler of double-section expansion chamber of automobile

A technology of expansion chamber and muffler, applied in the direction of intake muffler, muffler device, machine/engine, etc., to achieve the effect of wide muffler frequency range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

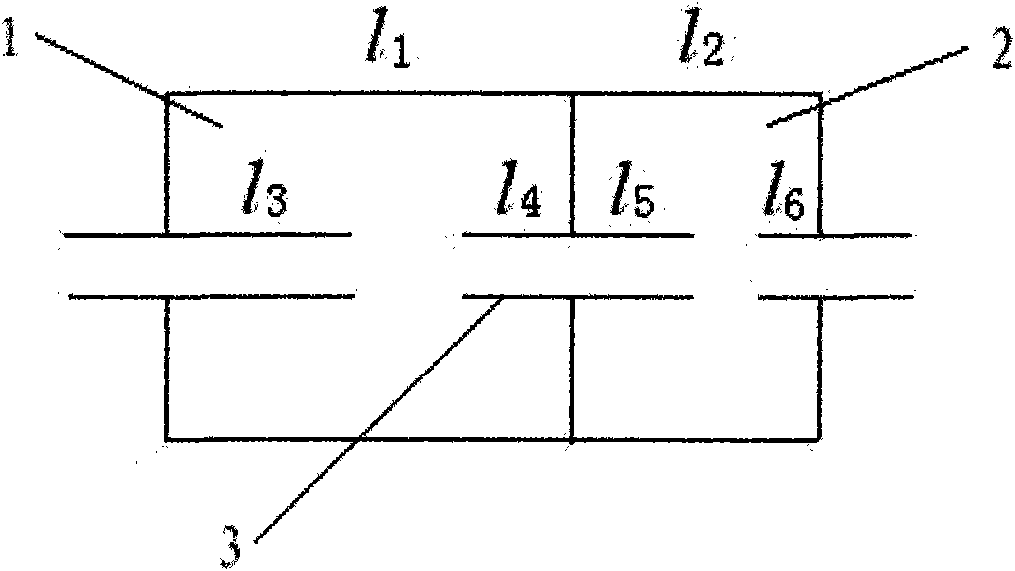

[0037] Such as image 3 As shown, the expansion chamber is composed of two left and right expansion chambers 1 and 2, and the inlet and outlet of each expansion chamber are provided with insertion tubes, wherein the inlet of the left expansion chamber and the outlet of the right expansion chamber share the same insertion tube 3. The double-section expansion chamber is in the shape of a cuboid as a whole, and the cross-section is a square. The cross-section of the expansion chamber is open at the center, and the diameters of the insertion tubes corresponding to the inlet and outlet of the expansion chamber are the same.

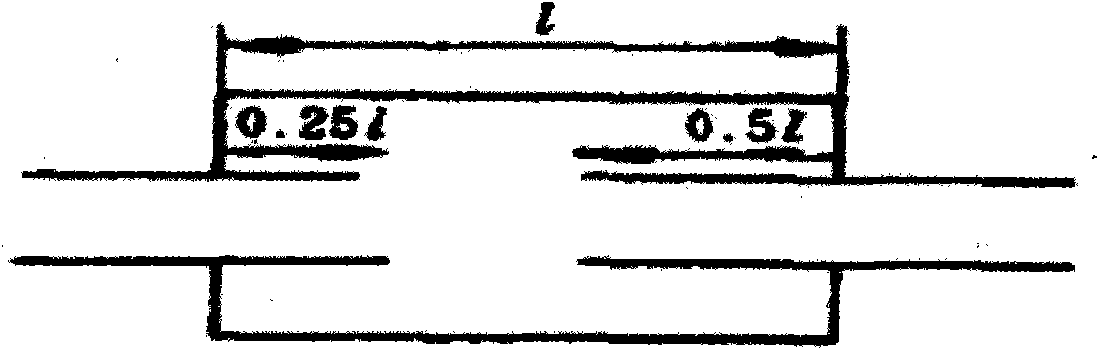

[0038] l 1 = 2l 2 , where l 1 is the length of the left expansion chamber 1, l 2 is the length of the right expansion chamber 2.

[0039] l 3 =1 / 2l 1 , l 4 =1 / 2l 2 , l 2 = l 3 = 2 l 4 = 2 l 5 = 4 l 6 , where l 3 is the length of the insertion tube at the inlet of the left expansion chamber in the expansion chamber, l 4 is the length of the inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com